A new crosslinked low MFR polymer composition, power cable insulation and power cable

A technology for power cables and compositions, applied in the field of cross-linked polymer compositions, capable of solving problems such as heat dissipation of insulating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

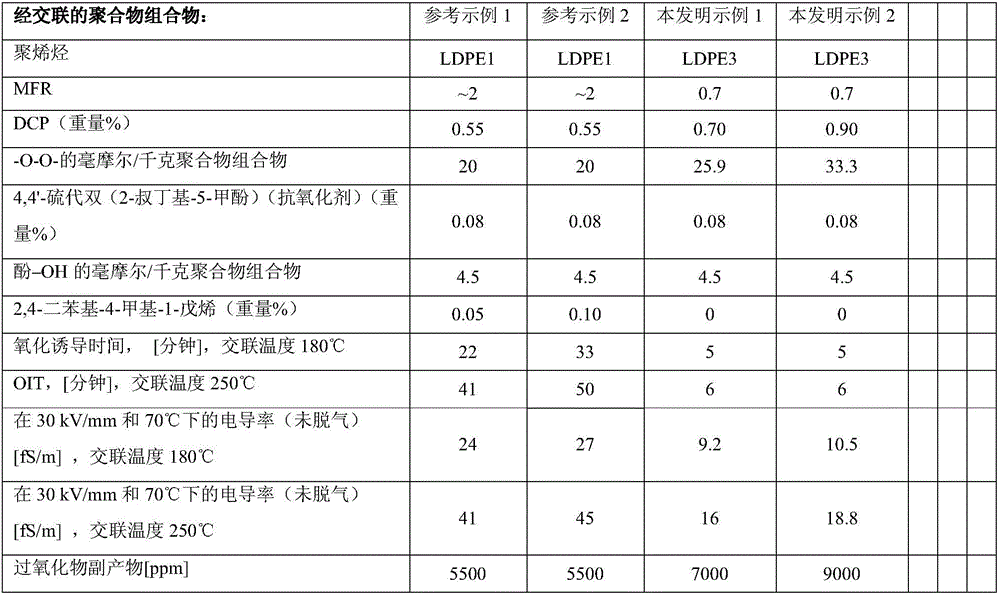

[0017] The present invention provides a crosslinked polymer composition obtained by crosslinking a polymer composition having a melt flow rate (MFR) of less than 1.7 and comprising polyolefin, peroxide and sulfur-containing antioxidants, characterized in that the crosslinked polymer composition has an oxidation induction time corresponding to Z minutes, determined with differential scanning calorimetry (DSC) according to ASTM-D3895, ISO / CD11357 and EN728 , and includes peroxide by-products in amounts corresponding to Wppm as determined by HPLC according to BTM2222, where

[0018] Z 1 ≤Z≤Z 2 , W 1 ≤W≤W 2 ,and

[0019] W≤p-270*Z, where

[0020] Z 1 is 0, Z 2 60, W 1 is 0 and W 2 is 9500, and p is 18500.

[0021] The crosslinked polymer composition comprises polyolefin and peroxide by-products in amounts as defined above, below or in the claims, and has an oxidation induction as defined above, below or in the claims time. The crosslinked polymer composition is crossli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com