A preparing method of an anti-shock polypropylene special-purpose material with a high melt index

A technology of polypropylene and high-melting fingers, applied in the production of bulk chemicals, etc., which can solve the problems of easy yellowing of polypropylene, limited application, and high content of volatile organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

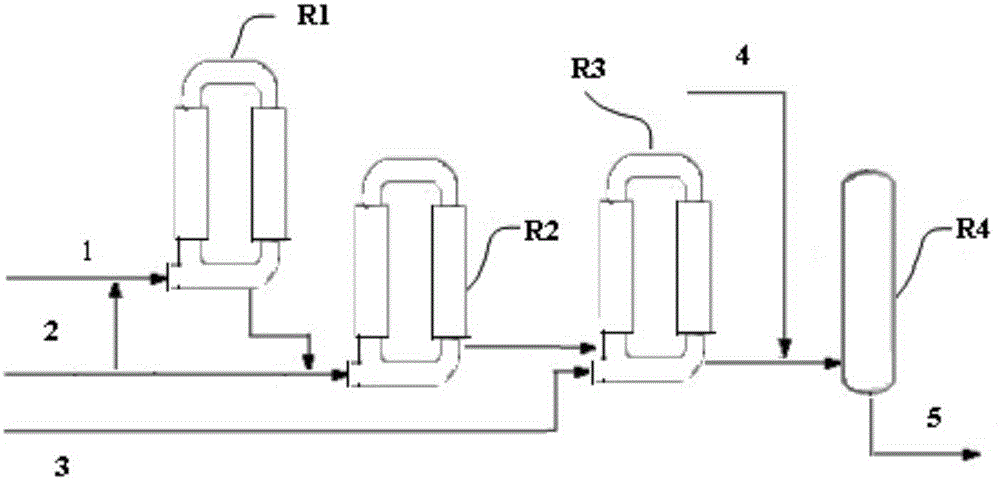

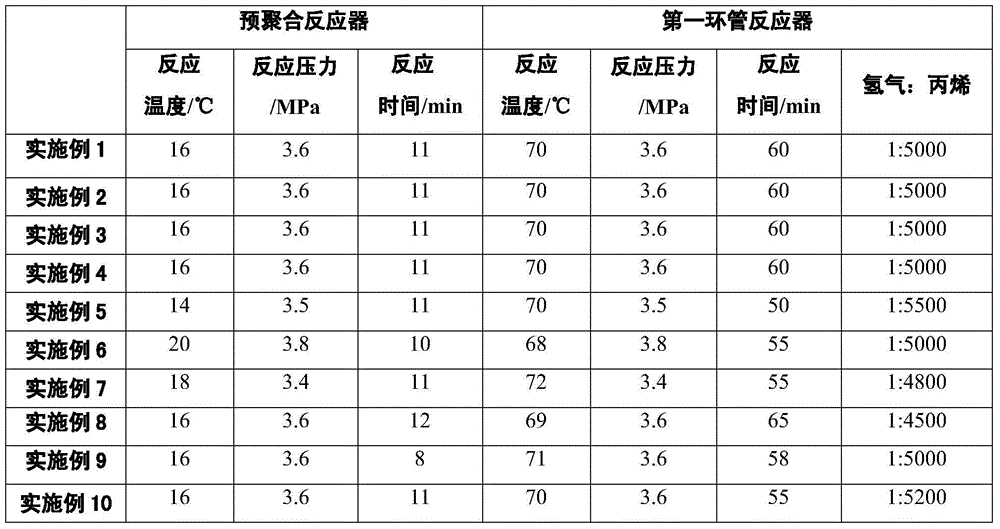

[0025] Under the joint action of the main catalyst, co-catalyst and external electron donor 1, propylene 2 undergoes pre-polymerization R1 (4L), the first loop reactor R2 (235L), the second loop reactor R3 (235L) and the gas phase Reactor R4 (950L) synthesizes polypropylene. During the synthesis process, the proportion of reaction raw materials, the amount of catalyst and the operating conditions of each reactor are shown in Table 1, Table 2 and Table 3. The indicators of polypropylene resin products are shown in Table 4

[0026] Table 1

[0027]

Cocatalyst: Propylene

Cocatalyst: external electron donor

Catalyst: Propylene

Example 1

1:6250

3

1:190000

Example 2

1:6250

1.5

1:170000

Example 3

1:6250

2.2

1:180000

Example 4

1:6250

1.8

1:180000

Example 5

1:5700

2

1:180000

Example 6

1:5700

2

1:190000

Example 7

1:6700

2

1:170000

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com