Method for rapid assessing high-temperature oxidation resistance of lubricating grease

A high-temperature anti-oxidation and anti-oxidation performance technology, applied in the field of grease, can solve the problems of restricting the development and research of grease products, low test temperature, long test time, etc., and achieve rapid monitoring of service life, good accuracy, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

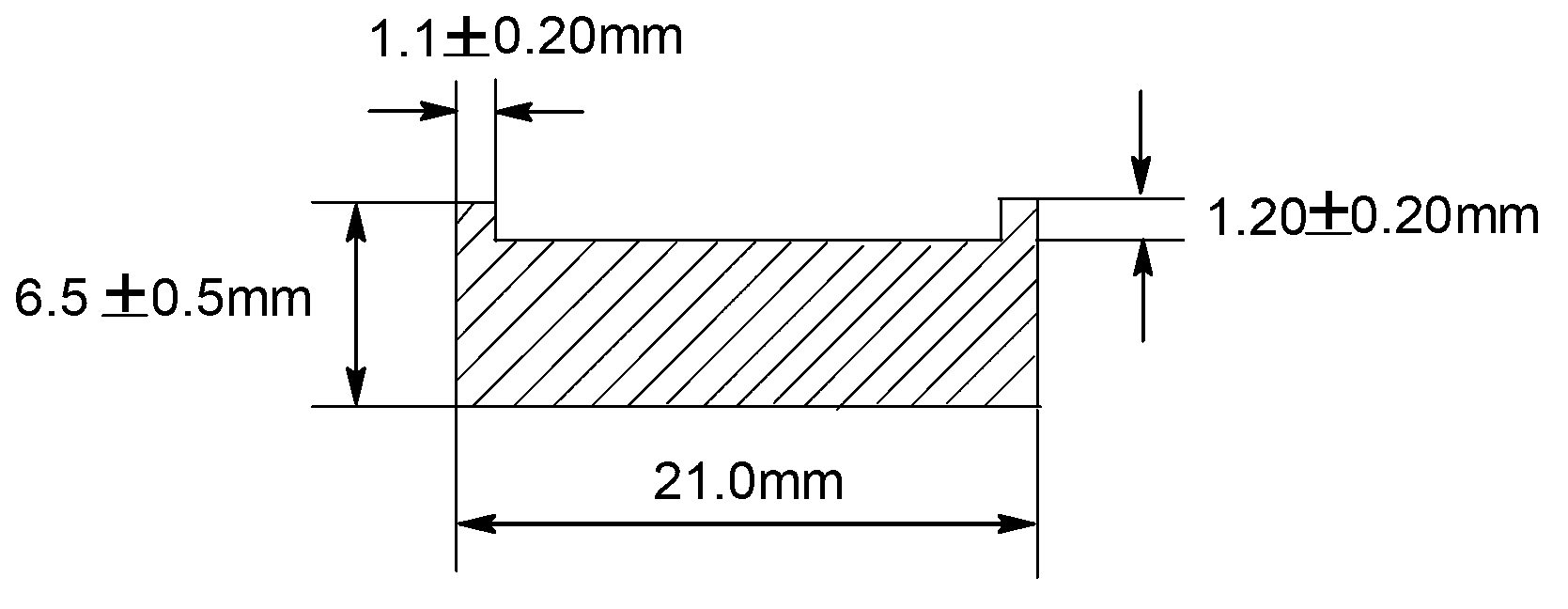

[0027] (1) Test conditions

[0028] The lubricating grease used in the test is self-prepared, in which sample component 1 is composed of lithium complex grease and 1.0% amine antioxidant; sample component 2 is composed of lithium complex grease, 1.5% amine antioxidant and 1.0% phenolic Antioxidant composition. The amount of test sample is 40mg, the low-carbon steel metal grease cup, the heating temperature is 220 ℃, no air is introduced, the oxidation time is 20min, 30min, 40min, 50min, 60min, 70min, the washing solvent is petroleum ether, analytically pure.

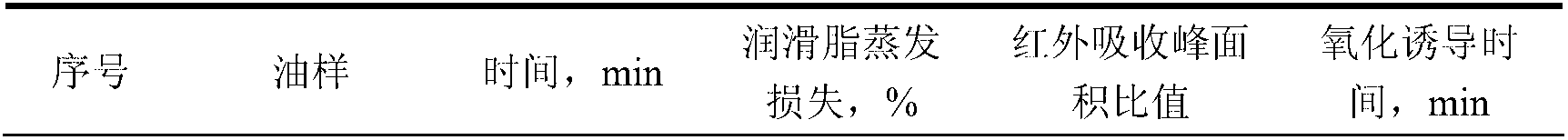

[0029] (2) Test results

[0030] Table 1 Oxidation performance test results of different grease components

[0031]

[0032]

[0033] From the evaporation loss results of sample component 1 and sample component 2 in Table 1, it can be seen that as the oxidation time increases, the evaporation loss of the grease gradually increases, and the oxidation degree of the grease continues to deepen. The evaporation loss ...

Embodiment 2

[0035] (1) Test conditions

[0036] The greases used in the test are commercially available calcium-based grease A, aluminum-based grease B, lithium-based grease C, and barium-based grease D. The amount of test sample is 20mg, the copper metal grease cup, the heating temperature is 180°C, and the air flow rate is 80mL·min -1 , the oxidation time is 40min, 50min, 60min. The washing solvent is isopropanol, analytically pure.

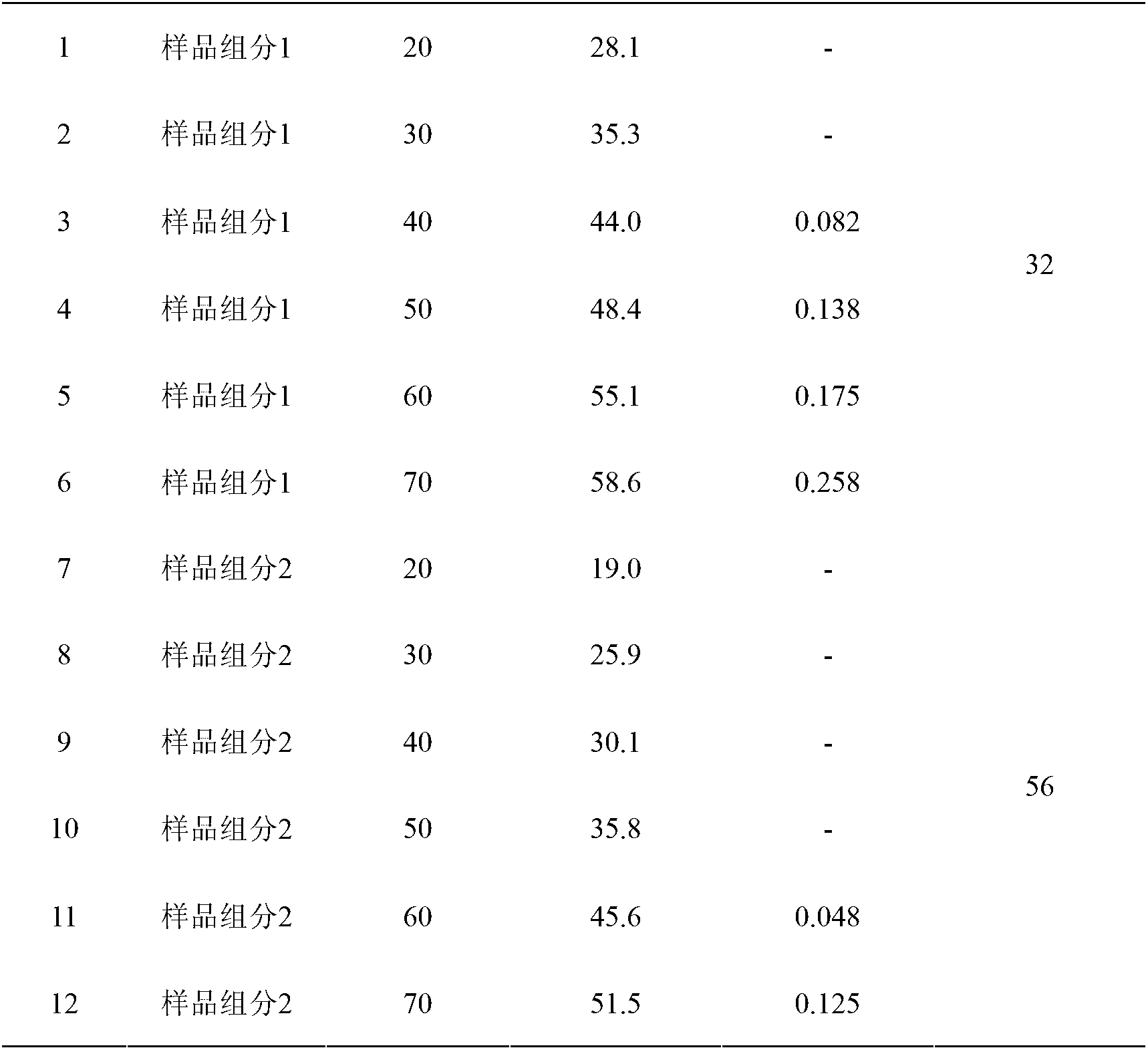

[0037] (2) Test results

[0038] Table 3 Oxidation performance test results of different soap base greases

[0039]

[0040] It can be seen from the measurement results of the oxidation properties of the four soap-based greases in Table 2 that in the inventive method, there is a good correlation between the evaporation loss value of each grease sample and its oxidation induction time at the same oxidation time It fully shows that the anti-oxidation behavior of lubricating grease is very related to the numerical value of the two indexes. By comparin...

Embodiment 3

[0042] (1) Test conditions

[0043] The greases used in the test are commercially available lithium complex grease D, calcium complex grease E, and aluminum complex grease F. The amount of test sample is 80mg, the steel metal grease cup, the heating temperature is 230°C, and the air flow is 20mL·min -1 , the oxidation time is 30min, 40min, 50min. The washing solvent is petroleum ether, analytically pure.

[0044] (2) Test results

[0045] Table 3 Oxidation performance measurement results of different complex soap base greases

[0046]

[0047]As can be seen from the measurement results of the oxidation properties of three kinds of complex soap-based greases in Table 3, in the inventive method, the evaporation loss value and the oxidation induction time of each grease sample under the same oxidation time are superior to those of composite lithium-based grease D. Composite calcium-based grease E and composite aluminum-based grease F; From the comparison of the measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com