Waste plastic recycling system

A technology of waste plastics and feeding, applied in cleaning methods and appliances, magnetic separation, solid separation, etc., can solve the problems of increasing the utilization rate of waste plastic raw materials, high recycling costs of waste plastics, and reducing investment in cleaning equipment, so as to reduce cleaning Equipment investment, simple structure, and the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

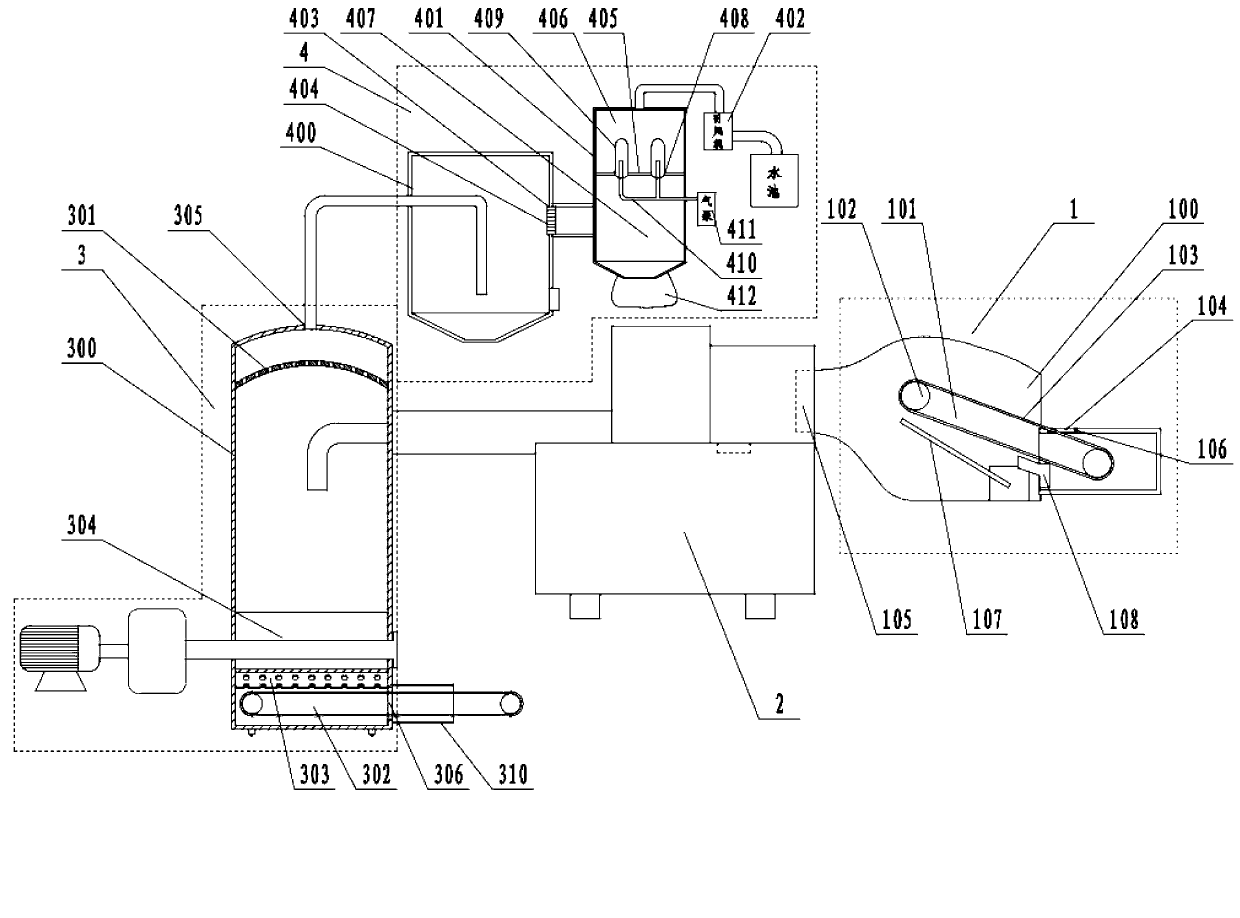

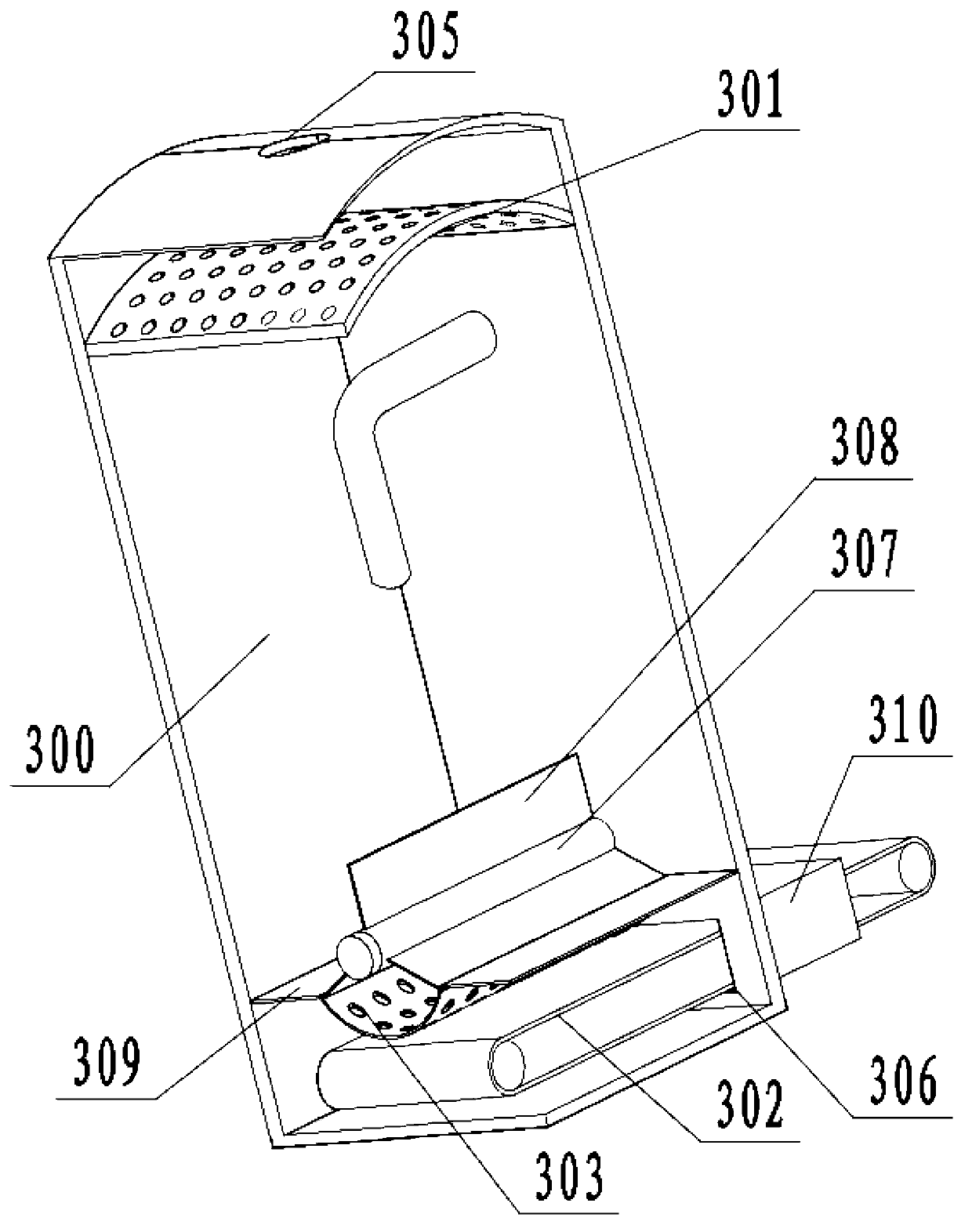

[0029] Embodiment 1: a kind of waste plastic recycling system (see attached figure 1 ), especially suitable for the recycling of waste plastics in the paper industry, including a feeding device 1, an extrusion device 2, a discharge device 3 and a dust suction device 4 connected in sequence. The feeding device comprises a closed feeding housing 100, and an inclined feeding conveying mechanism 101 is provided in the feeding housing. The feeding conveying mechanism includes two pulleys 102 and a conveyor belt 103 arranged on the two pulleys. Above the pulley at the feed end, the pulley at the discharge end has strong magnetism. The feed housing is provided with a rectangular feed port 104 and a discharge port 105 connected to the extrusion device. The side wall of the feed port is covered with a strong magnetic block 106. The bottom of the conveyor belt in the feed housing is provided with an inclined stop. Plate 107, one end of the baffle is close to the pulley position of the ...

Embodiment 2

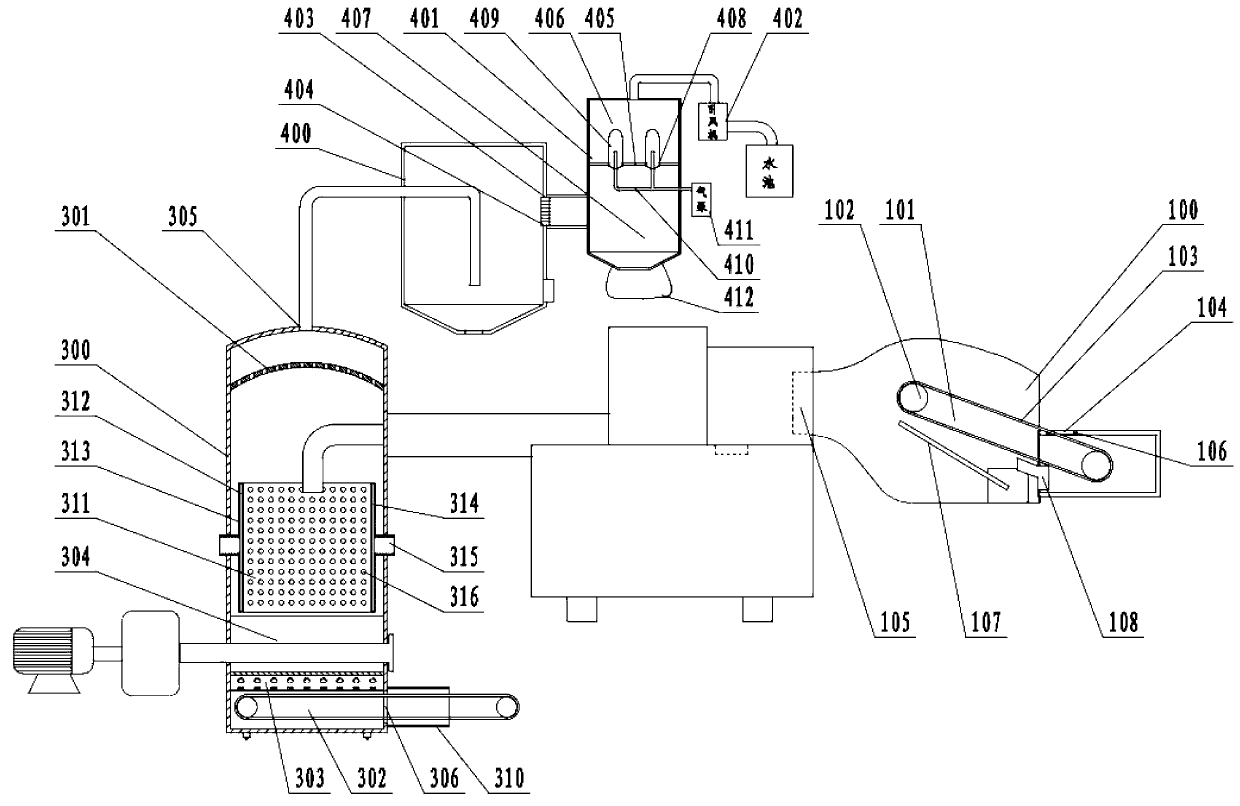

[0033] Embodiment 2: a kind of waste plastic recycling system (see attached image 3 ), its structure is similar to that of Example 1, the main difference lies in the discharge device (see attached Figure 4 )Structure. The upper end of the crushing mechanism in the discharge shell is fixedly connected with a vertical cooling cylinder 311. The cooling cylinder includes an inner cylinder 312 and an outer cylinder 313. The gap between the inner cylinder and the outer cylinder forms a cooling cavity 314, and the upper and lower ends of the cooling cavity are closed. The outer cylinder is provided with two water inlet pipes 315 communicating with the cooling chamber, and the inner cylinder wall is provided with several high-pressure injection holes 316 communicating with the cooling chamber, and the two water inlet pipes are connected with a high-pressure water pump. The axis of the high-pressure injection hole intersects the axis of the inner cylinder. Other structures are the ...

Embodiment 3

[0034] Embodiment 3: a kind of waste plastic recycling system (see attached Figure 5 ), its structure is similar to that of Example 2, the main difference lies in the discharge device (see attached Figure 6 ) structure and the structure of the feeding device. A filter cartridge 317 is fixedly connected above the cooling cylinder in the discharge housing, the axis of the filter cartridge is perpendicular to the axis of the cooling cylinder, and the two ends of the filter cartridge are fixedly connected to the inner wall of the discharge housing. Outer cylinder 319, there is a gap between the inner cylinder and the outer cylinder, several filter holes 320 are evenly distributed on the cylinder wall of the inner cylinder, and an extrusion filter is arranged on the cylinder wall of the outer cylinder close to the position directly above the cooling cylinder. Hole 321. On the outer wall of the discharge shell near the two ends of the filter cartridge, there are slag discharge h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com