Horizontal plastic waste recovering granulator

A technology of waste plastic and granulator, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of high crushing noise, dust, secondary pollution, etc., to avoid noise and dust, low energy consumption, environment-friendly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

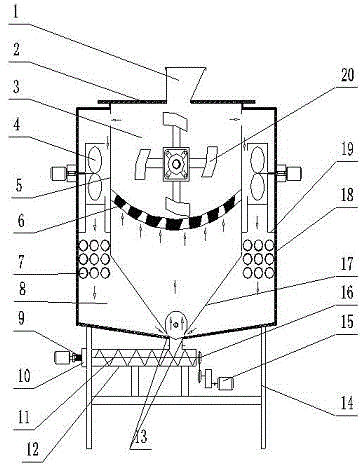

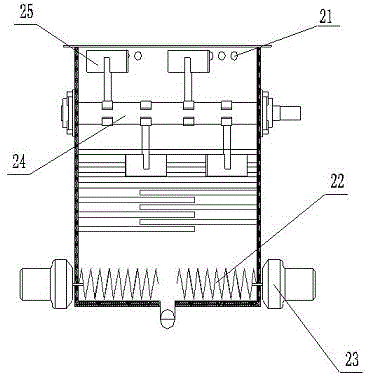

[0018] The overall structural schematic diagram of the horizontal waste plastic granulator of the present invention is as follows figure 1 and figure 2 As shown, its structure includes hopper (1), box cover (2), melting chamber (3), fan (4), square box (5), curved screen (6), heating pipe (7), hot air Circulation box (8), pelletizing mechanism (9), die (10), extrusion screw (11), barrel (12), circulating hot air inlet (13), frame (14), drive mechanism (15 ), transmission mechanism (16), V-shaped bucket (17), hot air circulation box shell (18), partition (19), stirring mechanism (20), exhaust gas circulation outlet (21), conveyor belt (22) , reducer (23), stirring shaft (24), stirring blades (25), a case cover (2) is installed above the melting chamber (3), a hopper (1) is arranged on the case cover (2), and the melting chamber ( 3) The outside is connected to the hot air circulation box (8), and the inside is equipped with a stirring mechanism (20). The bottom is a curved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com