Two-stage vacuum hot chemical treating and recovering process and apparatus for halogen-containing waste plastic

A technology for thermochemical treatment and waste plastics, which is applied in the field of two-stage vacuum thermochemical treatment and recovery devices for halogen-containing waste plastics. It can solve the problems of high halogen content, high cost, and inability to regenerate, so as to achieve complete separation of halogens and increase volatility. , the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

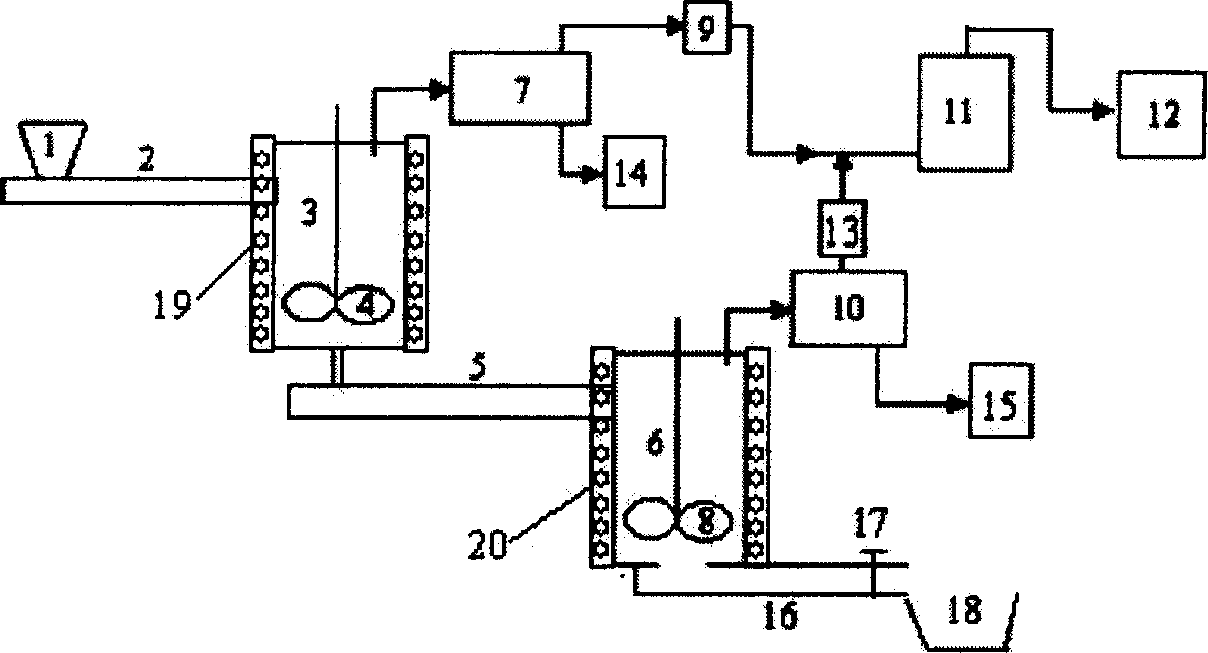

Image

Examples

Embodiment 1

[0028] The main plastic components are HIPS, ABS, PP and PS mixed plastic crushed materials for home appliance shells, and it is found that the main flame retardants are decabromodiphenyl ether, octabromodiphenyl ether, tetrabromobisphenol A, etc., containing bromine 10 %about.

[0029] Crushing and melting the above-mentioned halogen-containing waste plastics to obtain a melt;

[0030] The melt is melted and separated in a vacuum melting and separating tank with a temperature of 250°C and a pressure of 10kpa for 1 hour, and the flame retardant gas and other small molecule gases in the halogen-containing waste plastic melt volatilize; the volatilized flame retardant gas and other The small molecule gas is condensed, and the condensate is collected; the non-condensable gas produced is washed with lye, and then sent to the gas treatment system for treatment; the waste plastic melt after the flame retardant is separated is heated in a vacuum at a temperature of 500°C and a pressu...

Embodiment 2

[0033] The main plastic components are HIPS, ABS, PP and PS. The mixed plastics of the home appliance casing are analyzed and found that the main flame retardants are decabromodiphenyl ether, octabromodiphenyl ether, tetrabromobisphenol A, etc., containing about 10% bromine .

[0034] Crushing and melting the above-mentioned halogen-containing waste plastics to obtain a melt;

[0035] The melt is melted and separated in a vacuum melting and separating tank with a temperature of 350°C and filled with nitrogen atmosphere for 3 hours under normal pressure, and the flame retardant gas and other small molecule gases in the halogen-containing waste plastic melt volatilize; The fuel gas and other small molecular gases are condensed, and the condensate is collected; the non-condensable gas produced is washed with lye and sent to the gas treatment system for treatment; Pyrolysis in a vacuum pyrolysis tank of 5Kpa for 60 minutes.

[0036]The yield of flame retardant liquid was 18.9%, ...

Embodiment 3

[0038] The main plastic components are HIPS, ABS, PP and PS mixed plastic crushed materials for home appliance shells, and it is found that the main flame retardants are decabromodiphenyl ether, octabromodiphenyl ether, tetrabromobisphenol A, etc., containing bromine 10 %about.

[0039] Crushing and melting the above-mentioned halogen-containing waste plastics to obtain a melt;

[0040] The melt is melted and separated in a vacuum melting and separating tank with a temperature of 300°C and a pressure of 5kpa for 2 hours, and the flame retardant gas and other small molecule gases in the halogen-containing waste plastic melt volatilize; the volatilized flame retardant gas and other The small molecular gas is condensed, and the condensate is collected; the non-condensable gas produced is washed with lye and sent to the gas treatment system for treatment; the waste plastic melt after the flame retardant is separated is heated in a vacuum at a temperature of 550 ° C and a pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com