Household garbage refined classifying system and treatment method

A technology of refined classification and waste purification, applied in chemical instruments and methods, grain processing, solid separation, etc., can solve the problems of inability to achieve separation processing and fine classification processing requirements, and achieve low cost and high efficiency Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

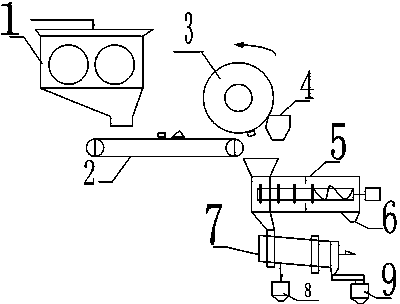

[0040] like Figure 1 to Figure 7 as shown,

[0041] Refined domestic waste classification system, including a conveyor 2, a garbage crusher 1 and a magnetic separator 3 are arranged above the conveyor 2, the outlet of the garbage crusher faces the upper surface of the conveyor 2, and the discharge port of the conveyor 2 A plastic recycling machine 5 is arranged below, a trommel 7 is arranged below the outlet of the plastic recycling machine 5, and a composting raw material bin 8 and an incineration raw material bin 9 are arranged under the drum sieve.

[0042] In the above system, the garbage is crushed by the garbage crusher 1; the garbage is put on the conveyor 2, and the garbage is placed on the conveyor 2 flat; the magnetic separator 3 is used to absorb and separate the metal objects on the conveyor 2; the plastic The recycling machine 5 separates the plastic bags in the garbage; the drum sieve 7 is used to separate the composting raw materials of small particles into th...

Embodiment 2

[0053] The processing method based on the fine classification system of domestic waste includes the following steps:

[0054] A. Garbage shredding step: shred the garbage through the garbage shredder 1;

[0055] B. Conveying step: put the garbage after step A on the conveyor 2, and place the garbage on the conveyor 2 evenly;

[0056] C. Metal body sorting step: adopt magnetic separator 3 to absorb and separate the metal objects on conveyor 2;

[0057] D, plastic bag separation step: adopt plastic recycling machine 5 to separate the plastic bags in the garbage;

[0058] E. Separation of composting raw materials and separation of incineration raw materials: using drum sieve 7 to separate small particles of composting raw materials into composting raw material bin 8, and using drum sieve 7 to separate small particles of incinerated raw materials into incineration raw material bin 9.

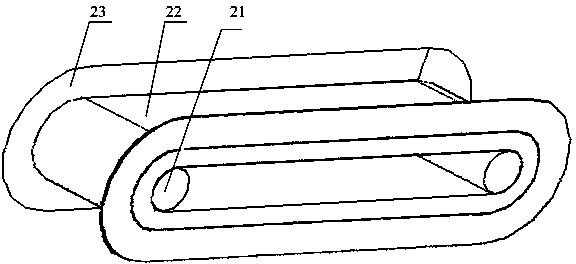

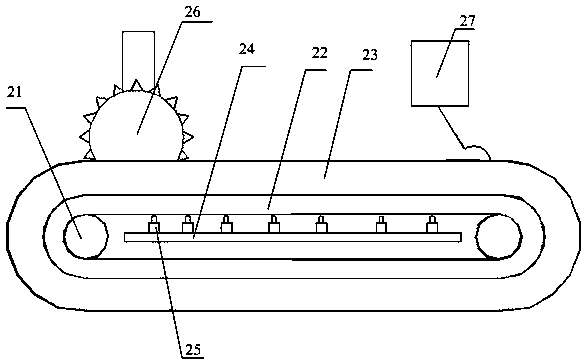

[0059] In the conveying step, the rubbish is leveled by using the carding machine 26 for stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com