Waste rubber plastic toughening device

A plastic and toughening technology, applied in the field of waste rubber and plastic toughening equipment, can solve the problem of high cost, achieve good effect, prevent excessive temperature, and facilitate exhaust air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

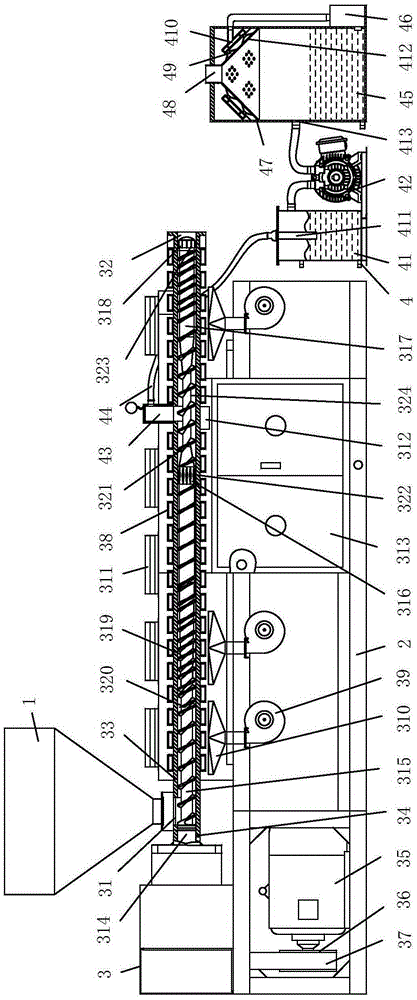

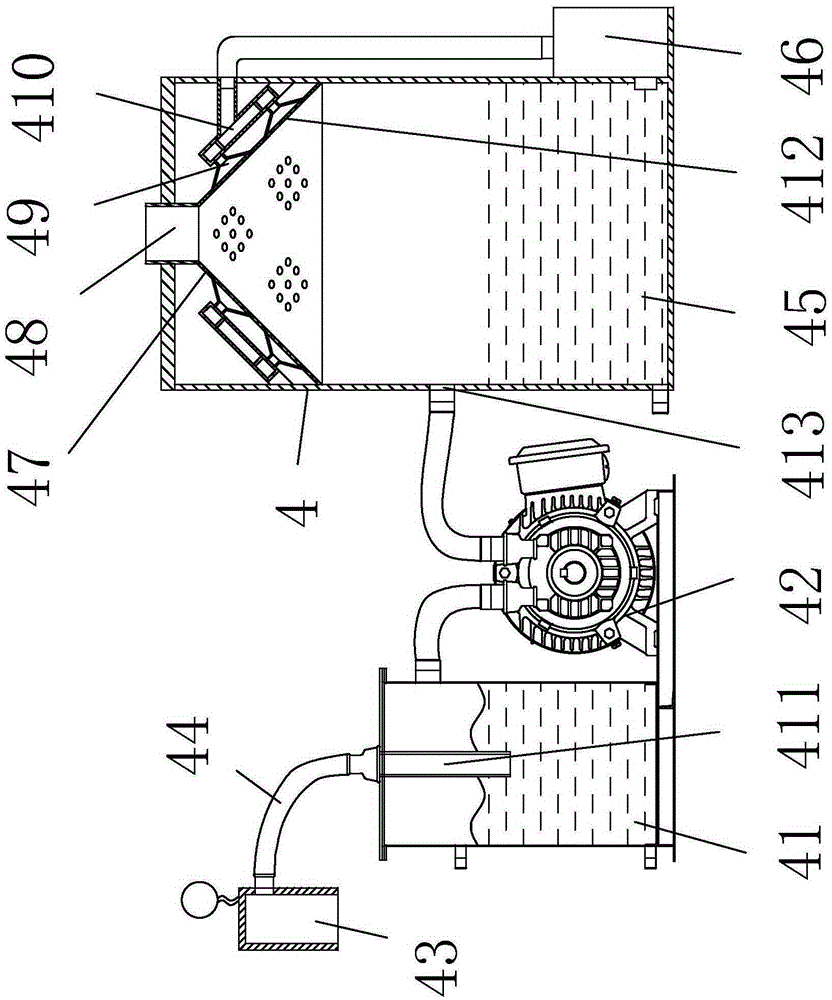

[0018] as attached figure 1 , attached figure 2 , attached image 3 Shown: a waste rubber and plastic toughening equipment, including a frame 2 with a hopper 1, a toughness enhancing device 3 connected to the outlet of the hopper 1 with a feed inlet 31, and a vacuum degassing device connected to the toughness enhancing device 3 at the inlet device 4.

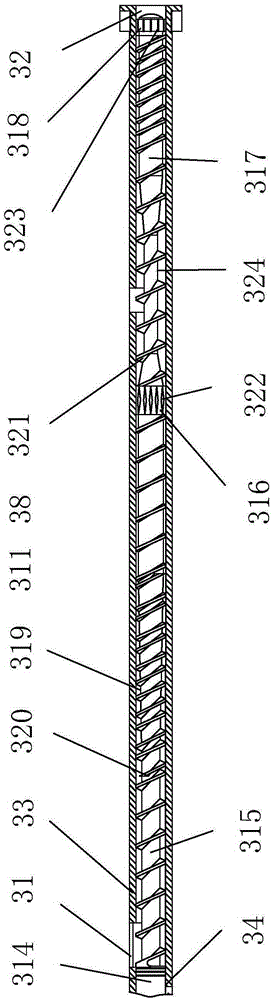

[0019] The toughness enhancing device 3 includes: a cylinder 33 screwed to the frame 2, a screw push rod 34 pivotally connected to the cylinder 33, a motor 35 screwed to the frame 2, and a keyed connection with the output shaft of the motor 35 The driving wheel 36, the driven wheel (not shown in the accompanying drawings) that is keyed to the rear end of the screw push rod 34, the transmission belt 37 that is respectively connected to the driving wheel 36 and the driven wheel, and the heating tube 38 that is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com