Rubber and plastic plasticizing and toughening machine

A rubber and plastics and toughening machine technology, applied in the field of rubber and plastics processing, can solve the problems of rubber and plastic impurities with more toughness and less toughness, and achieve the effect of low cost, simple and practical structure, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

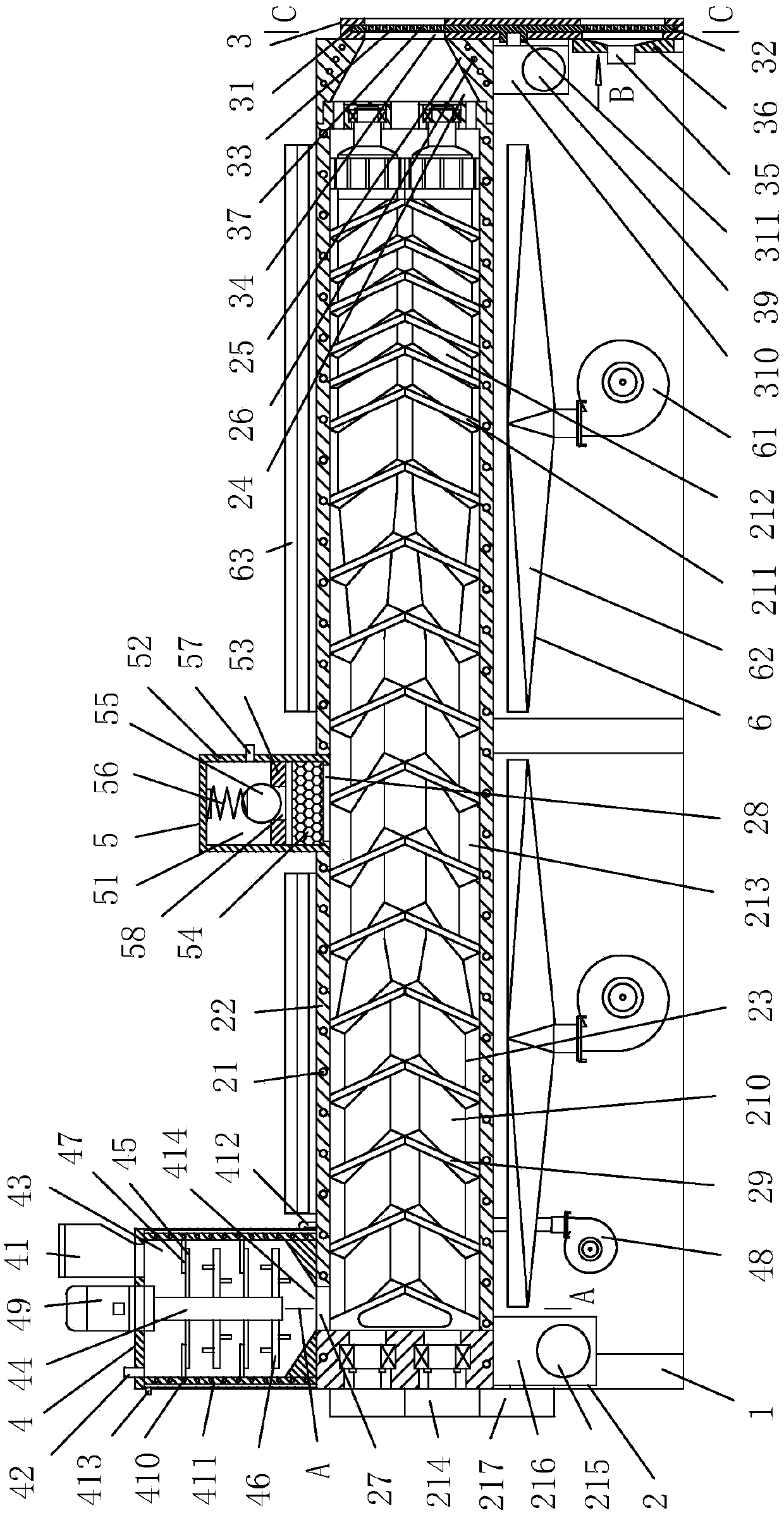

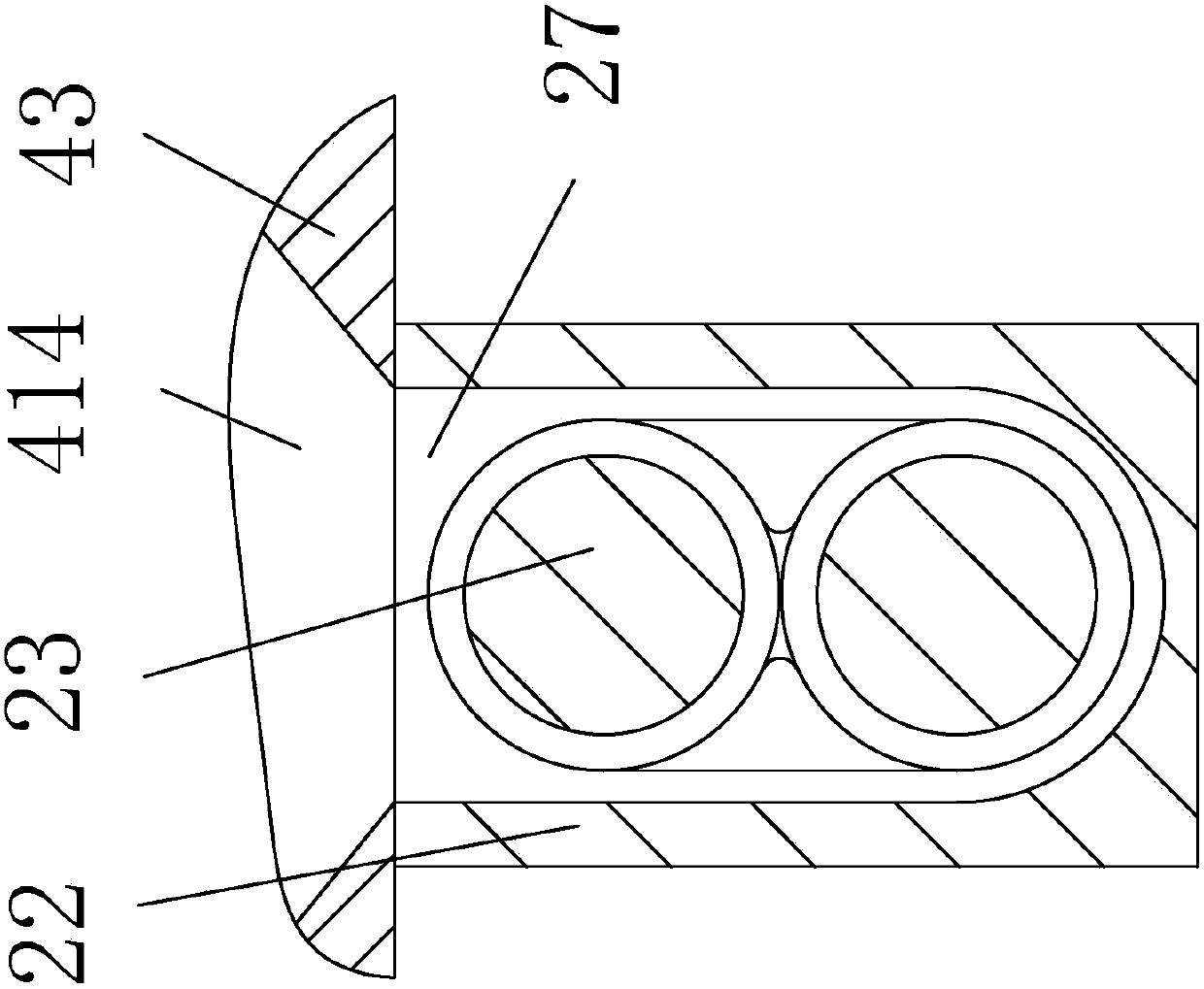

[0022] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 Shown: a rubber and plastic plasticizing and toughening machine, including a frame 1, a plasticizing and toughening device 2, a filtering device 3, a pre-plasticizing device 4, an exhaust device 5, and a cylinder cooling device 6.

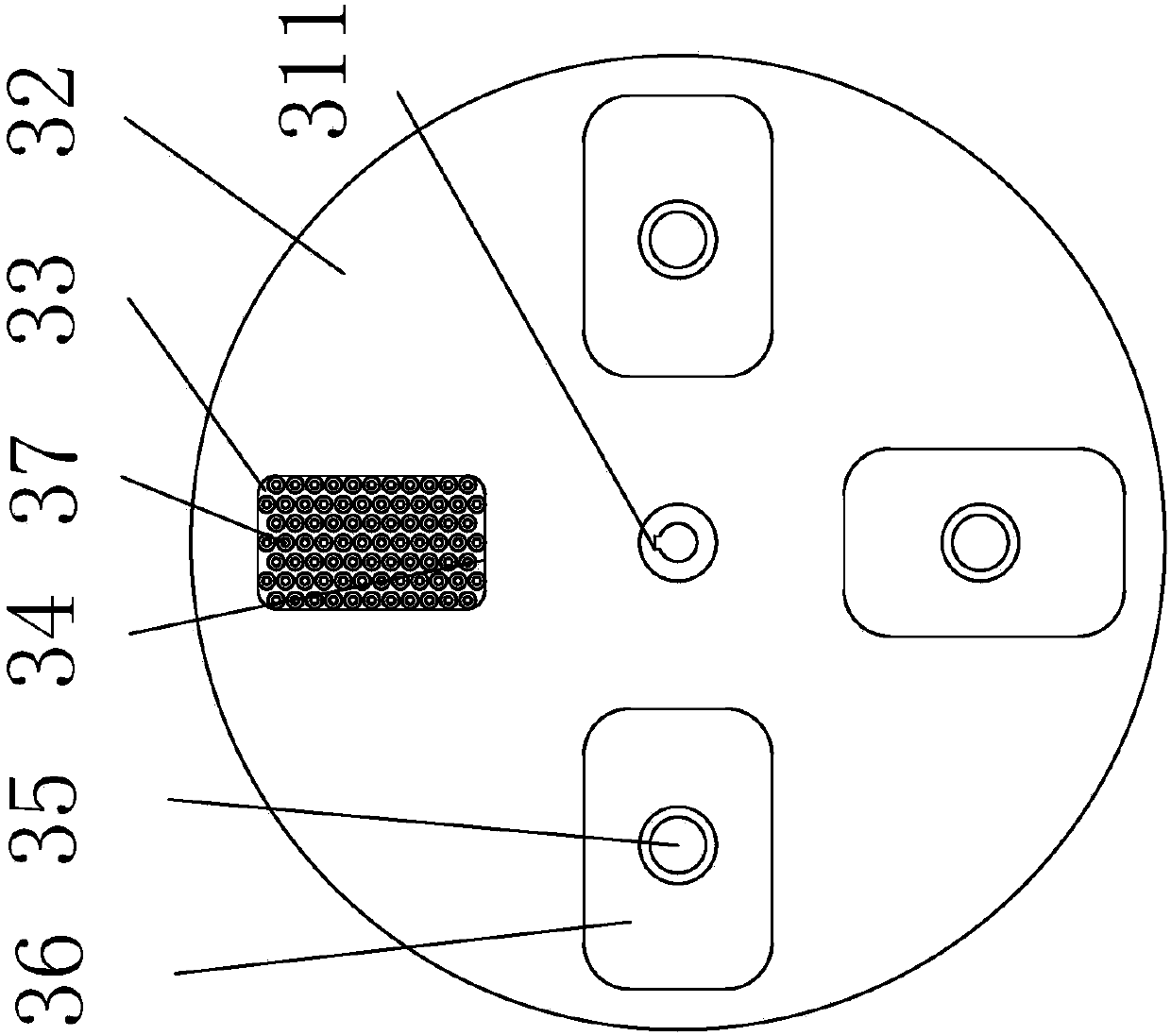

[0023] Described filtering device 3 comprises the turntable seat 32 that is provided with circular cavity 31, is positioned at circular cavity 31 and is provided with the turntable 33 of several filter hole groups uniformly distributed along the circumference, and the turntable that is connected with frame 1 Driving device; the turntable seat 32 is provided with several through holes 34 corresponding to the filter hole groups; the rear end of the first through hole 34 communicates with the outlet end of the plasticizing and toughening device 2; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com