Cap and label removal device for plastic bottles

A technology for plastic bottles and bottle caps, which is applied in the direction of plastic recycling and recycling technology, etc., can solve the problems of affecting the working stability of the device, the label is easy to stick to the fan, and cannot be quickly and completely separated from the label, etc., to avoid the label sticking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] see Figure 1 to Figure 6 , the present invention provides a technical solution:

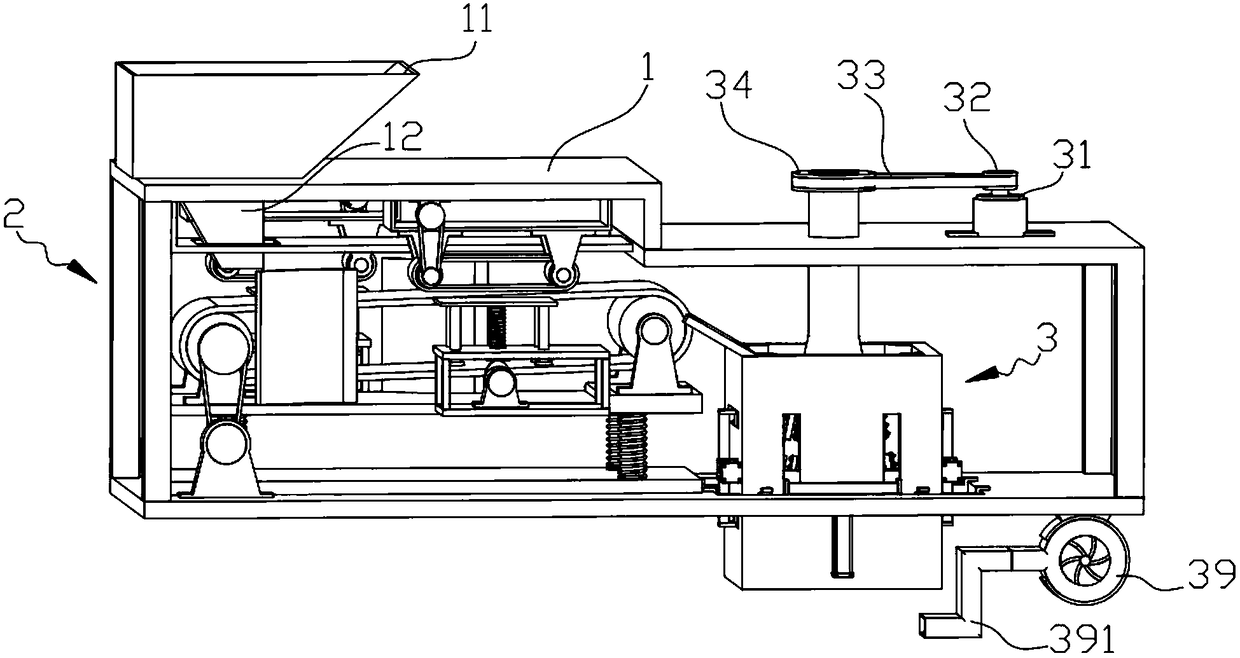

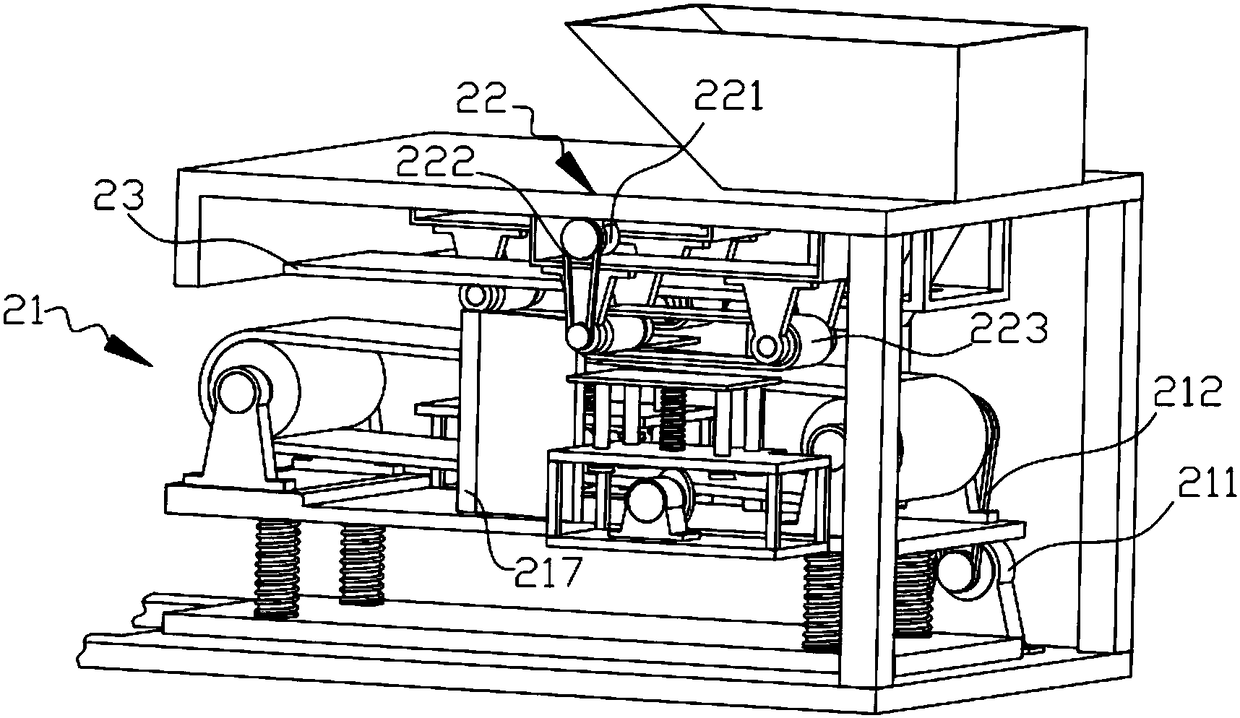

[0029] A device for removing caps and labels from plastic bottles, comprising a frame 1, a cap removal mechanism 2 and a labeling mechanism 3, wherein:

[0030] A hopper 11 is arranged on the top of the frame 1 , wherein the lower side of the hopper 11 is fixedly connected with a feed pipe 12 and communicates with it, wherein the end of the feed pipe 12 not connected with the hopper 11 extends to the conveyor belt 213 .

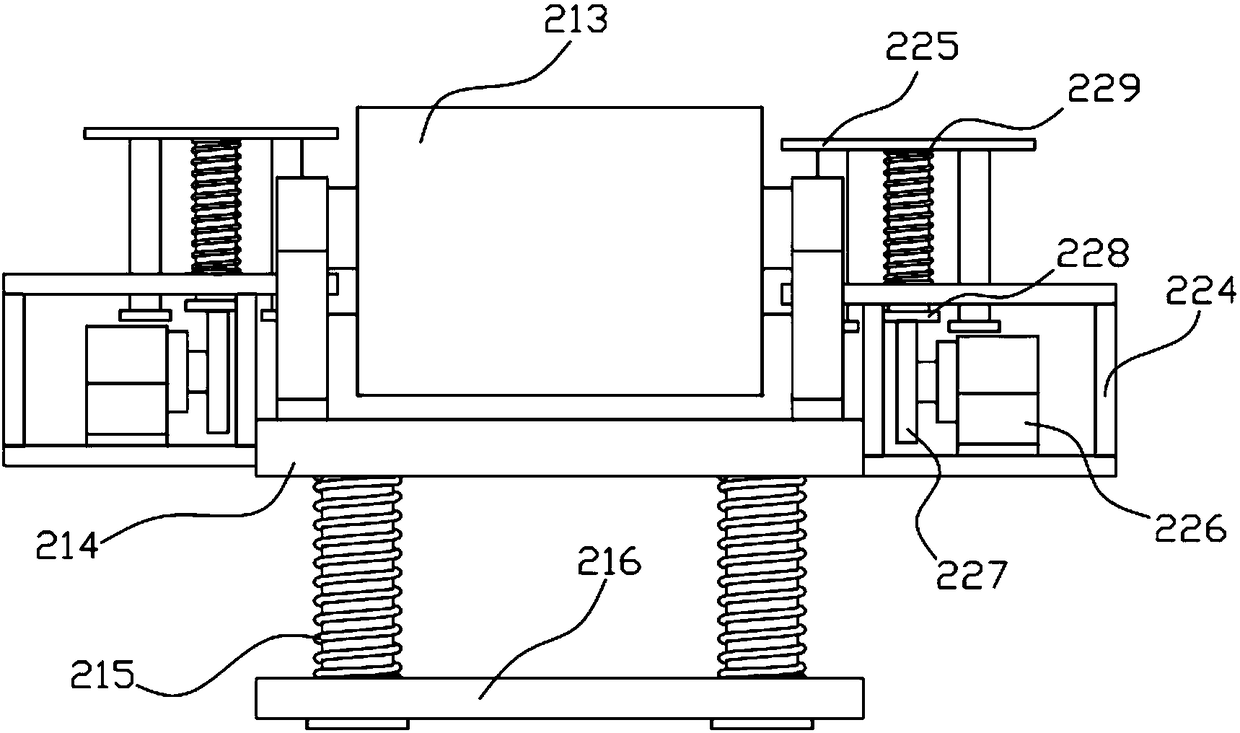

[0031] The bottle cap removal mechanism 2 includes a flexible conveying mechanism 21, a cap removing mechanism 22 and an upper baffle 23, the two cap removing mechanisms 22 are installed on both sides of the flexible conveying mechanism 21, and the upper baffle 23 is welded on the frame 1 , the upper baffle plate 23 is located directly above the conveyor belt 213 and has a gap with the conveyor belt 213, wherein the flexible conveyor mechanism 21 includes a motor I 211,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com