Waste plastic recycling dewatering machine

A waste plastic and dehydrator technology, applied in plastic recycling, recycling technology, dryers and other directions, can solve the problems of seal failure, easy deformation of the casing, long dehydration time, etc., to protect the bearing seat, support reliable, work well reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific examples.

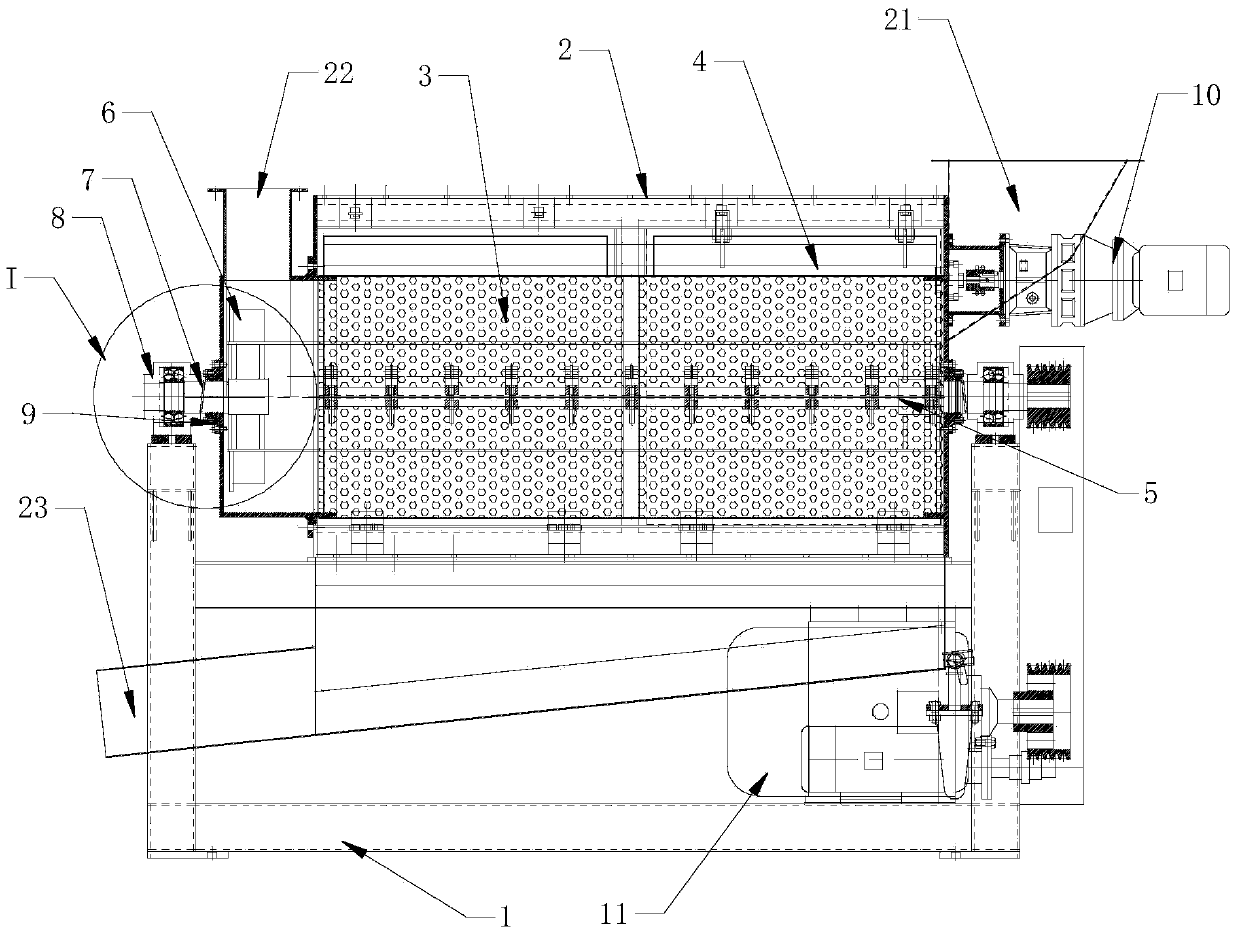

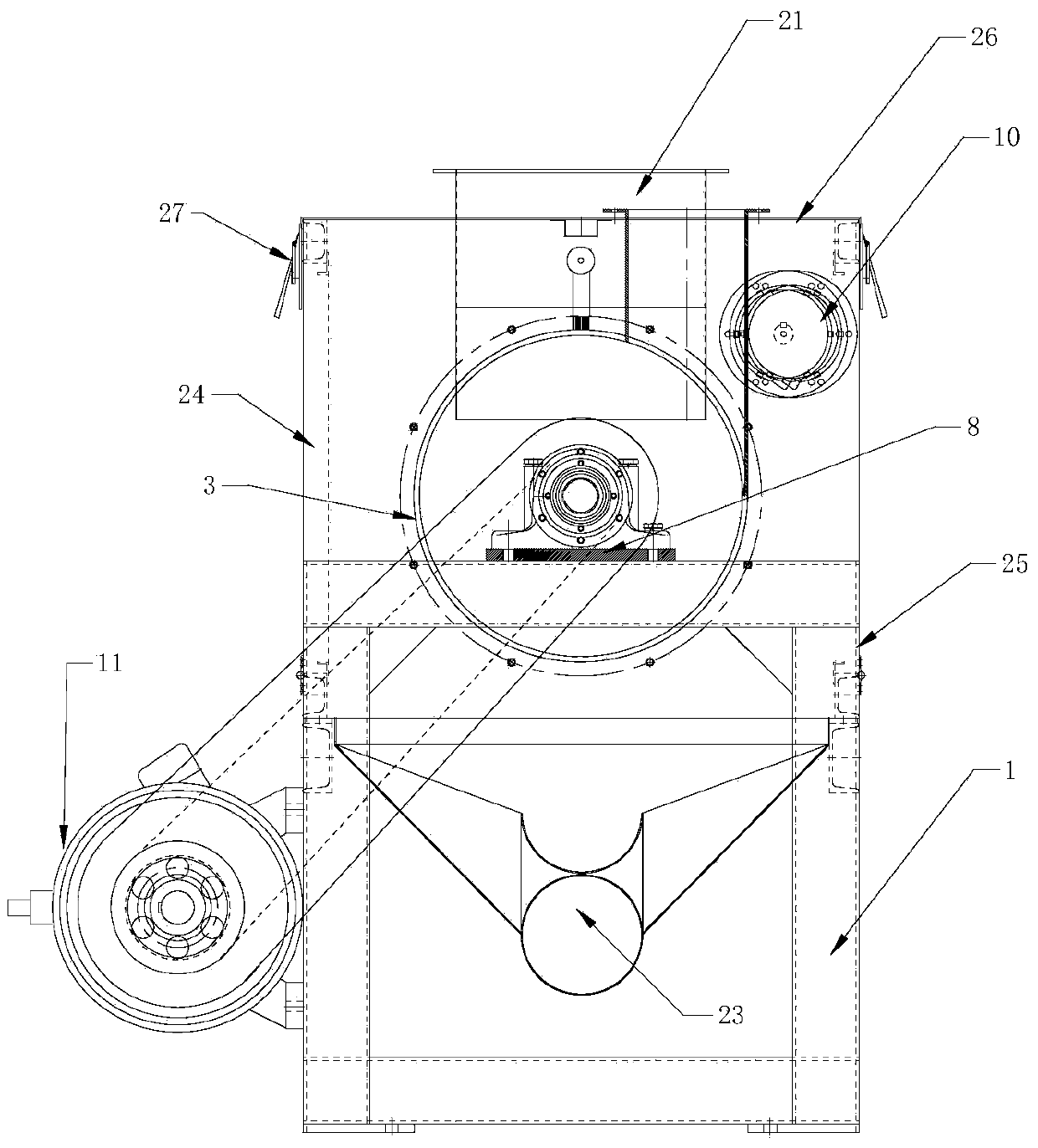

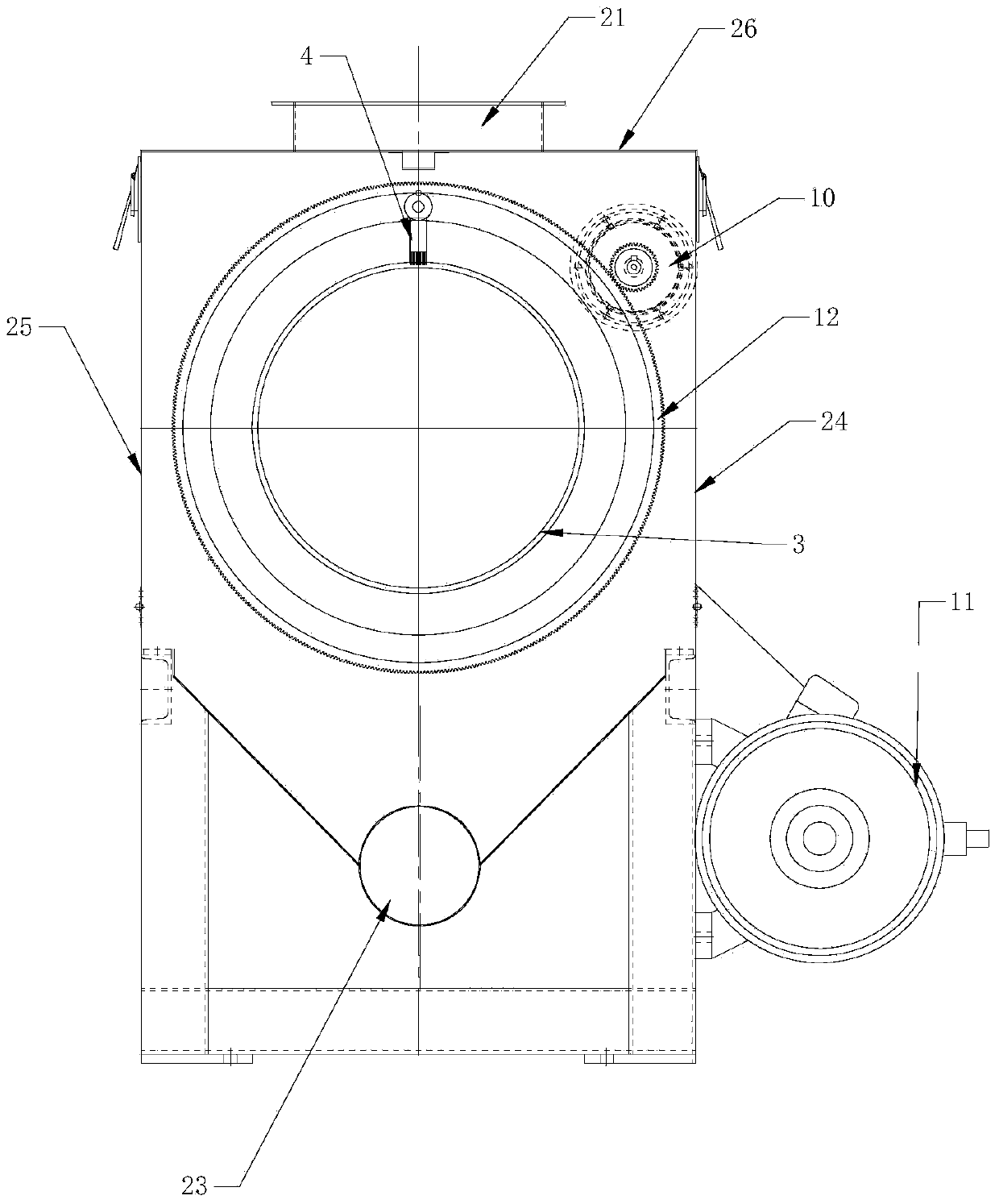

[0023] like figure 1 As shown, a waste plastic recycling dehydrator includes a base 1, a casing 2, a sieve drum and a main shaft 5 with stirring blades, the casing 2 includes a frame and a bottom plate, an upper side cover 26, a front side cover 24 and a rear Side cover 25 and two end plates, two end plates are fixed on the end of frame, and two end plates are provided with the through hole that is convenient to main shaft 5 to pass through, and upper side cover 26 is fixed on the top of frame by bolt, front side The lower ends of the cover 24 and the rear side cover 25 are hinged to the frame, and the upper ends of the front side cover 24 and the rear side cover 25 are locked and fixed with the upper side cover 26 by the buckle structure 27. Like this, the casing 2 is very easy to open. It provides greater convenience for screen replacement, internal maintenance and repairs, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com