Cleaning machine

A rack and screw shaft technology, applied in the field of cleaning equipment, plastic film and PET bottle flakes cleaning machines, can solve the problems of inability to clean specific gravity plastic films, inability to continuously discharge materials, etc., to achieve high production efficiency, continuous and stable discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

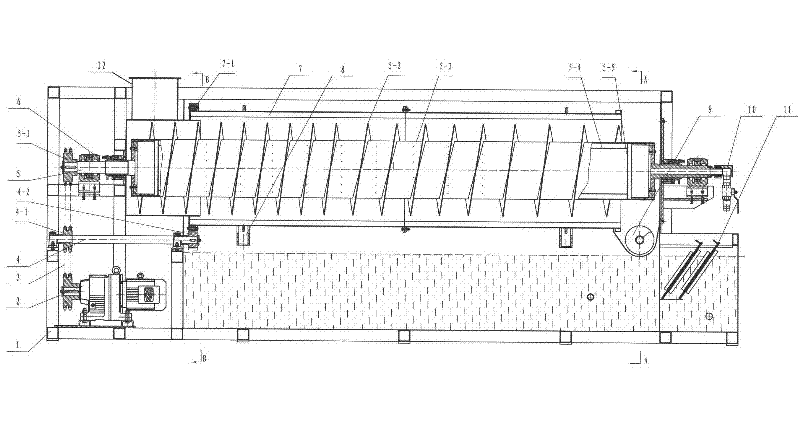

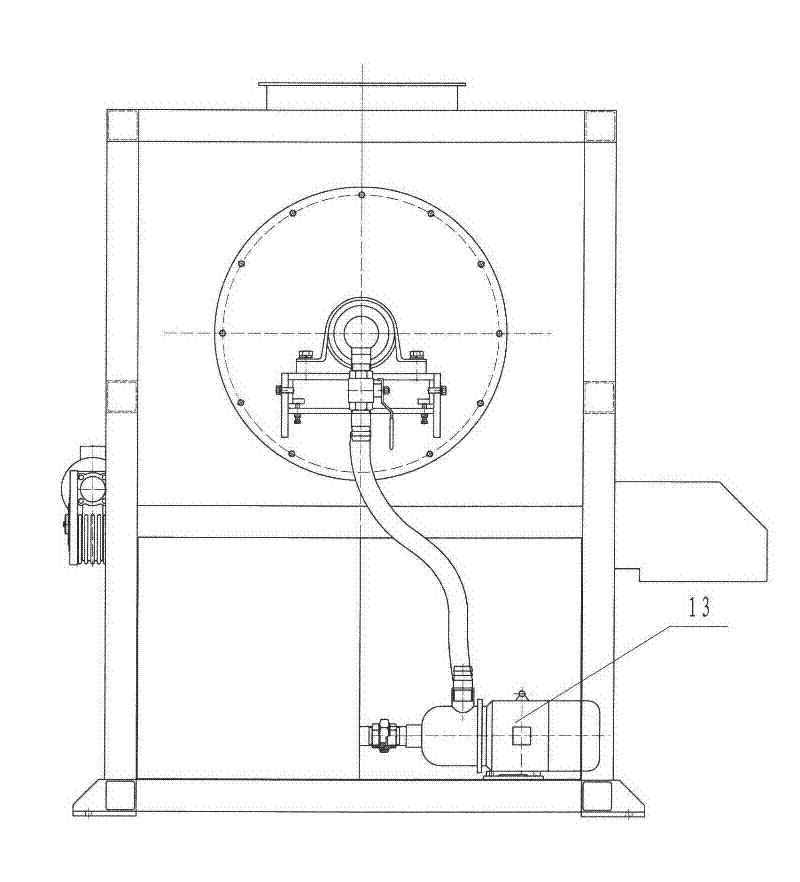

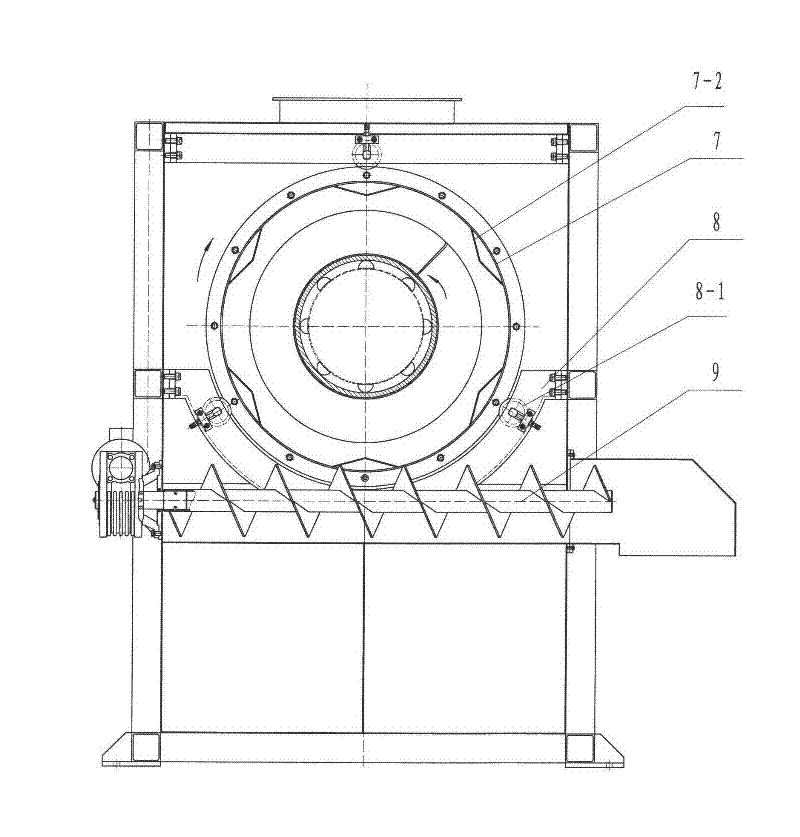

[0012] exist Figure 1 to Figure 4 Among them, a water tank is provided in the frame (1) for storing alkaline water, a filter plate (11) and a water pump (13) are installed on the right side of the water tank, and a reducer (1) is installed on the left side of the frame (1). 2) and the transition wheel assembly (4), the left end shaft of the transition wheel assembly (4) is equipped with sprocket wheel (4-1), and the right end shaft is equipped with pinion (4-2). A bearing assembly (6) is respectively installed at the left and right ends of the upper part of the frame (1), and the left and right ends of the screw shaft (5) pass through the bearing assembly (6) respectively, and a chain is installed on the left end shaft of the screw shaft (5). Wheel (5-1), the shaft at the right end of the screw shaft (5) is a hollow structure, and an inner bag (5-4) is arranged in the cylinder (5-3) of the screw shaft (5), and the inner bag (5-4) The length is less than the cylinder body (5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com