Ore crushing device

An ore pulverizing and crushing device technology, applied in the field of ore, can solve the problems of not meeting people's needs, unable to pulverize ore, poor pulverization effect, etc., and achieve the effect of reasonable design, good pulverization effect, and complete pulverization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

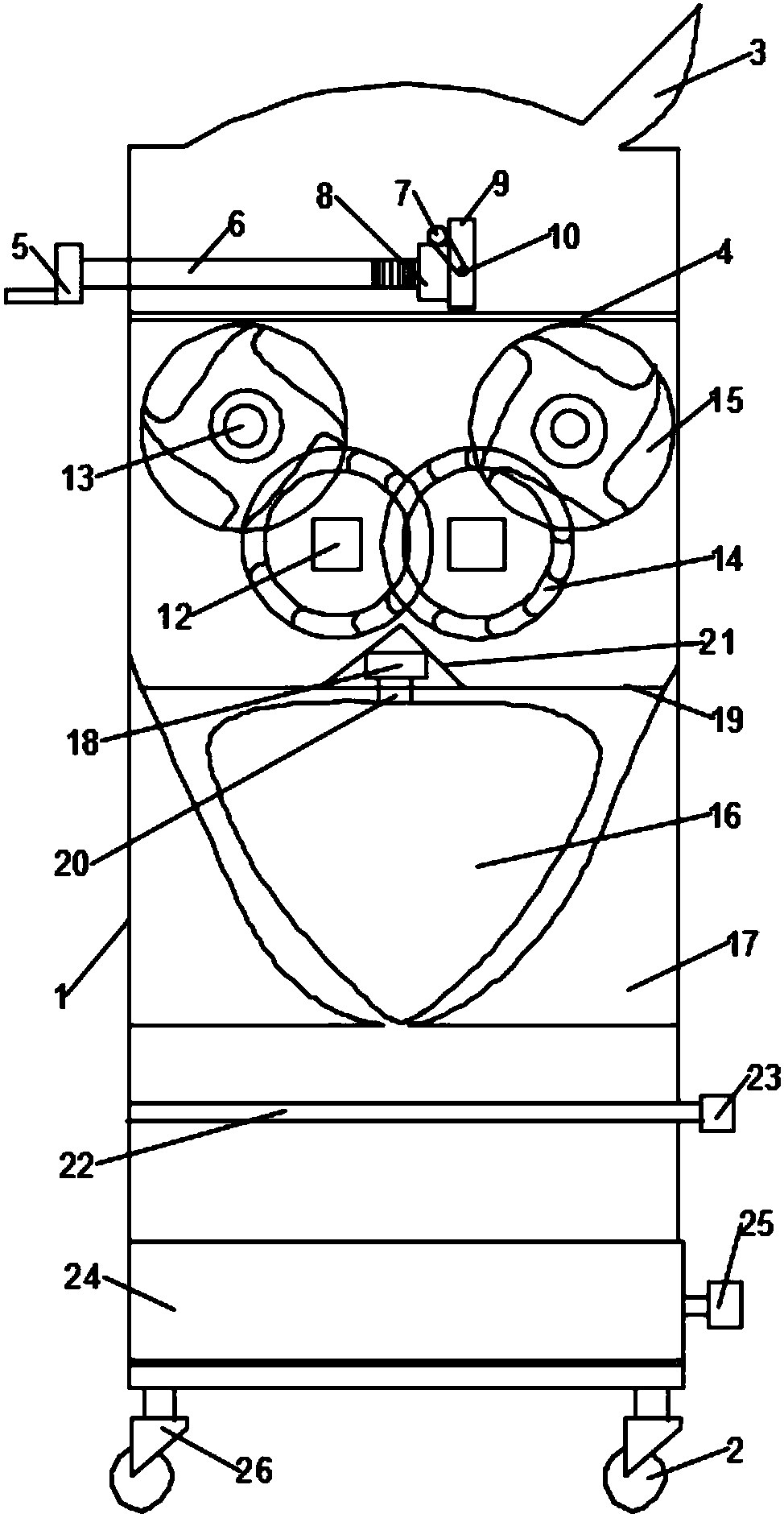

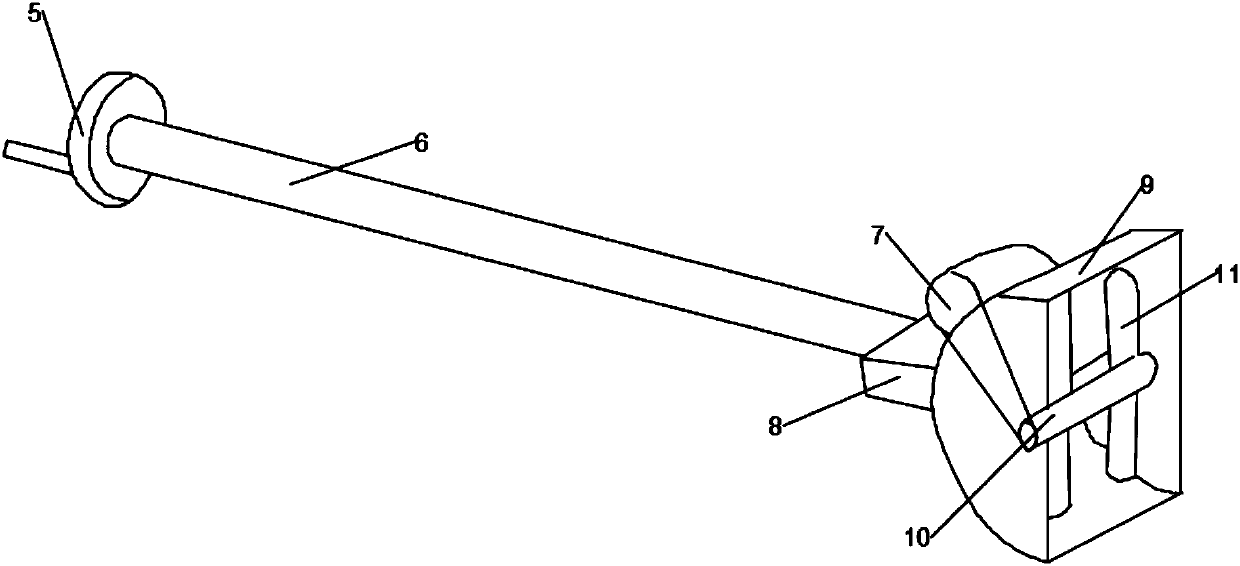

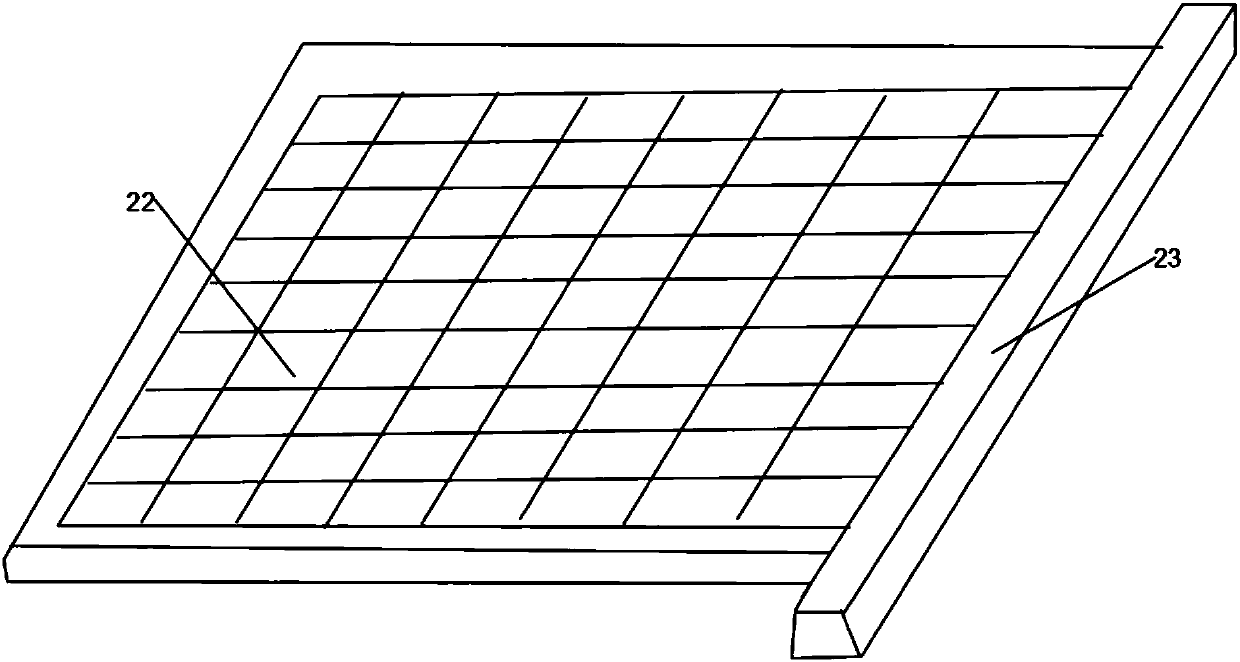

[0019] see Figure 1-3 , an ore crushing device, comprising a body 1, universal wheels 2 are installed at the four corners of the bottom of the body 1 and each universal wheel 2 is provided with a brake fixing member 26, and the top of the body 1 is provided with a feed hopper 3 , the inside of the body 1 is equipped with a beating device, a crushing device and a grinding device, the beating device is located below the feed hopper 3 and the lower end of the beating device is provided with a first screen 4, the first screen 4 is detachably connected to the body 1 Inside, the beating device includes a hand crank 5, an explosion-proof motor 7, a hammer shield 9, a rotating shaft 10 and a hammer 11, the hand crank 5 is installed outside the body 1, and the explosion-proof motor 7 is connected to the hammer shield 9 through a motor holder 8. The hammer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com