Building waste crushing apparatus

A crushing device and construction waste technology, applied in the field of construction machinery, can solve the problems of unsorted metal, incomplete crushing, large structure, etc., and achieve the effect of easy operation, thorough crushing, and convenient crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

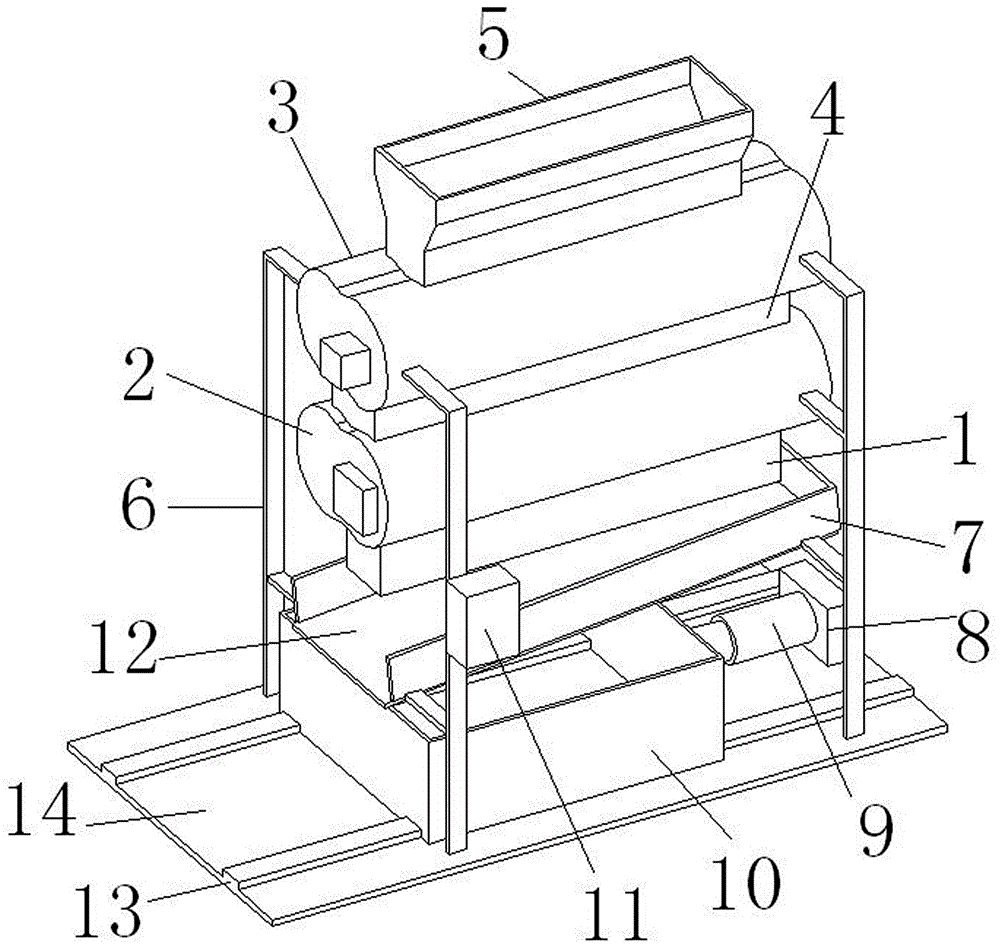

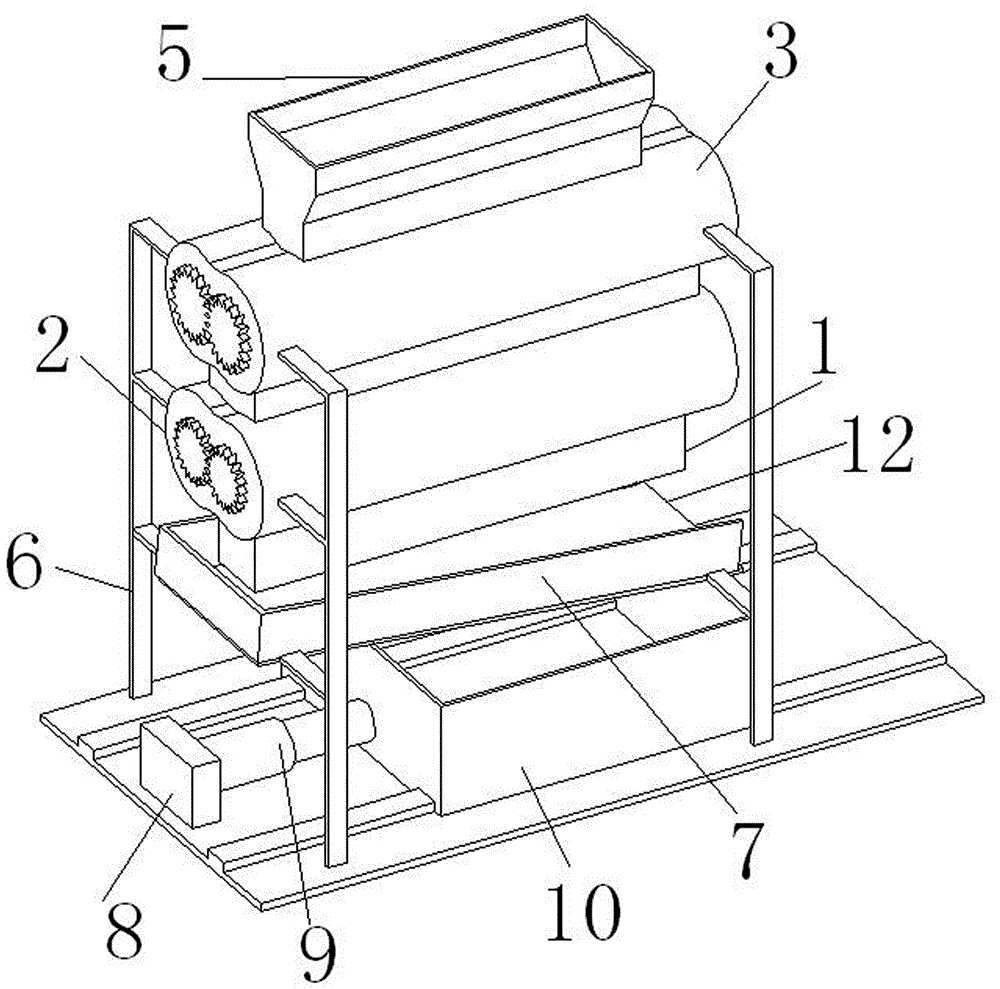

[0025] A construction waste crushing device, comprising a bottom plate 14, two corresponding support frames 6 are arranged on the upper surface of the bottom plate 14 close to two opposite long sides, and there is a primary crushing device between the upper ends of the four support frames 6 3.

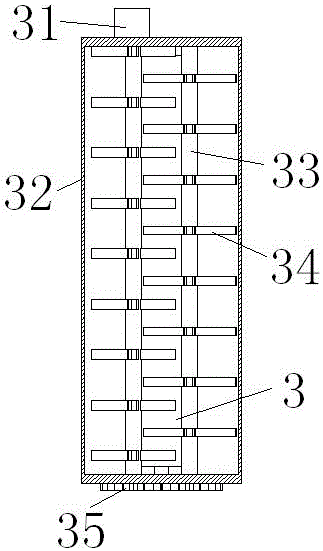

[0026] The primary crushing device 3 comprises a first crushing shell 32 and two rotating shafts 33; the upper end of the first crushing shell 32 is provided with a feeding port, and the upper end of the charging port is provided with a feeding chute 5, and construction waste can be fed from the feeding chute. 5 into the first crushing shell 32, the lower end of the first crushing shell 32 is provided with a discharge port; two rotating shafts 33 are installed in parallel in the first crushing shell 32, and the two ends of the rotating shaft 33 are respectively supported by a bearing on the On the first crushing shell 32; each of the two rotating shafts 33 is provided with mutually sta...

Embodiment 2

[0031] On the basis of Embodiment 1, the lower end of the discharge chute 1 is provided with an electromagnetic plate 12, the metal in the crushed construction waste can be absorbed by the electromagnetic plate 12, and a 15 is provided between the electromagnetic plate 12 and the upper surface of the bottom plate 14 -25 degrees of bevel, and around the upper surface of the electromagnetic plate 12 is provided with a frame 7, through the frame 7 can prevent the crushed construction waste from running out from the side, and the frame 7 at the lower end of the electromagnetic plate 12 is provided with an opening, and the electromagnetic The both sides of plate 12 are connected with support frame 6 by connecting column, and the output end of control switch 11 is electrically connected the input end of electromagnetic plate 12, and the input end of control switch 11 is electrically connected the output end of external power supply, and the upper surface of bottom plate 14 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com