Intelligent crushing treatment equipment

A technology of intelligent equipment and crushing chamber, which is applied in grain processing, chemistry, etc., can solve the problems of low efficiency of medical waste crushing and processing, and achieve the effects of improving crushing processing efficiency, fast crushing speed, and thorough crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

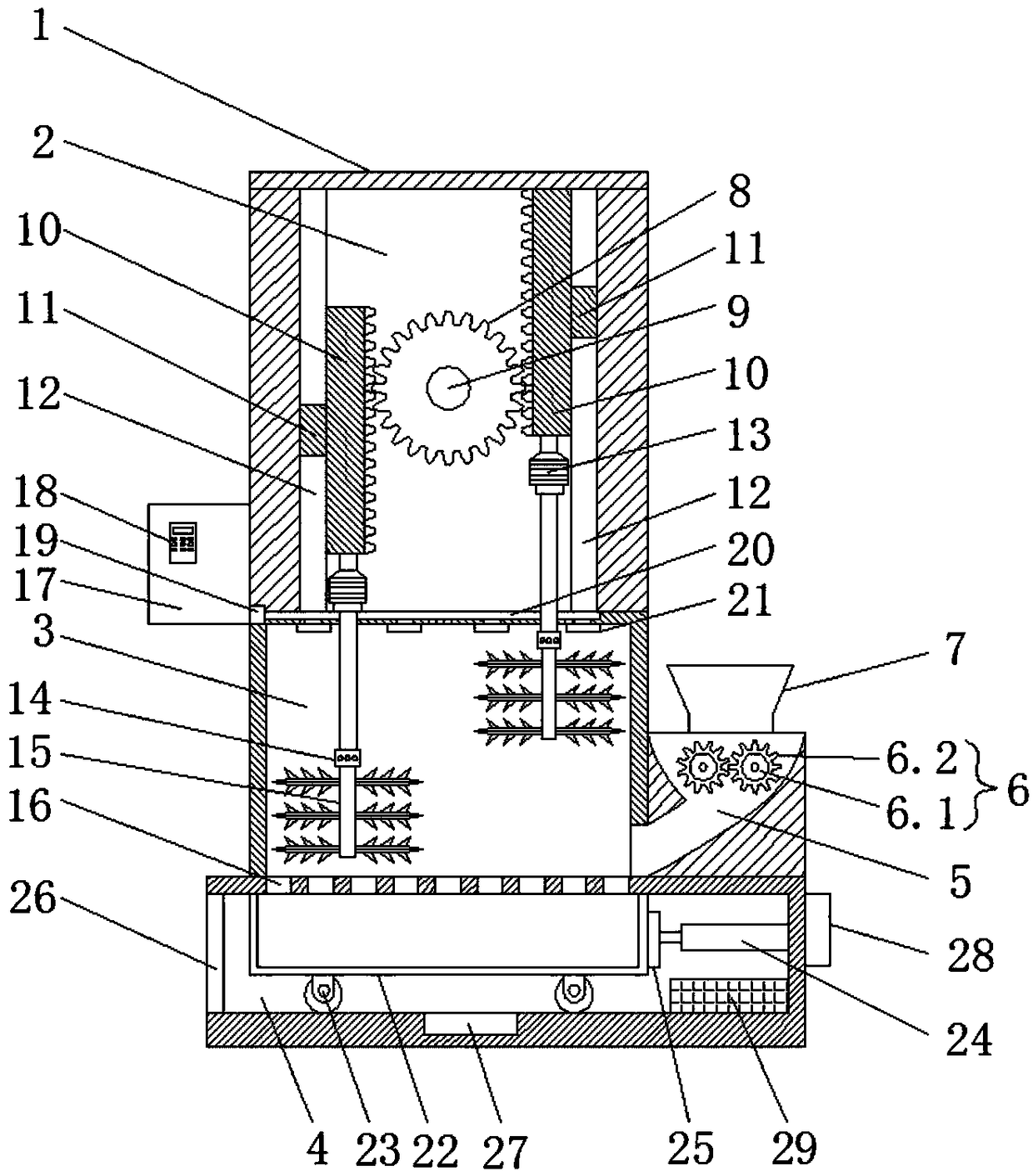

[0025] Such as Figures 1 to 2 As shown, this embodiment provides an intelligent crushing device, including a casing 1, in which a drive chamber 2, a secondary crushing chamber 3 and a collection chamber 4 are sequentially arranged from top to bottom, and the outer wall of the secondary crushing chamber 3 A first-stage crushing chamber 5 connected to the second-stage crushing chamber 3 is provided. A crushing mechanism 6 is arranged in the first-stage crushing chamber 5. A driving gear 8 is arranged in the driving chamber 2. The driving gear 8 is connected with a forward and reverse motor 9. Both sides of the driving gear 8 are meshed with a vertical rack 10, the back of the rack 10 is provided with a guide slider 11, and the inner wall of the drive chamber 2 is provided with a guide chute 12 cooperating with the guide slider 11. The bottoms of each rack 10 are connected with a rotating motor 13, and the output shafts of the rotating motor 13 extend into the secondary crushing...

Embodiment 2

[0028] Such as figure 1 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the top of the primary crushing chamber 5 is provided with a feeding funnel 7 located directly above the crushing mechanism 6, and the crushing mechanism 6 It includes two rolling rolls 6.1 rotating inwards, and the surface of the rolling rolls 6.1 is provided with a number of rolling teeth 6.2.

[0029] In this embodiment, after adding medical waste from the feeding hopper, two inwardly rotating rollers with rolling teeth roll in the medical waste, and at the same time perform a preliminary crushing and rolling process on the medical waste. , to promote the effect and speed of the follow-up shredding treatment of medical waste.

Embodiment 3

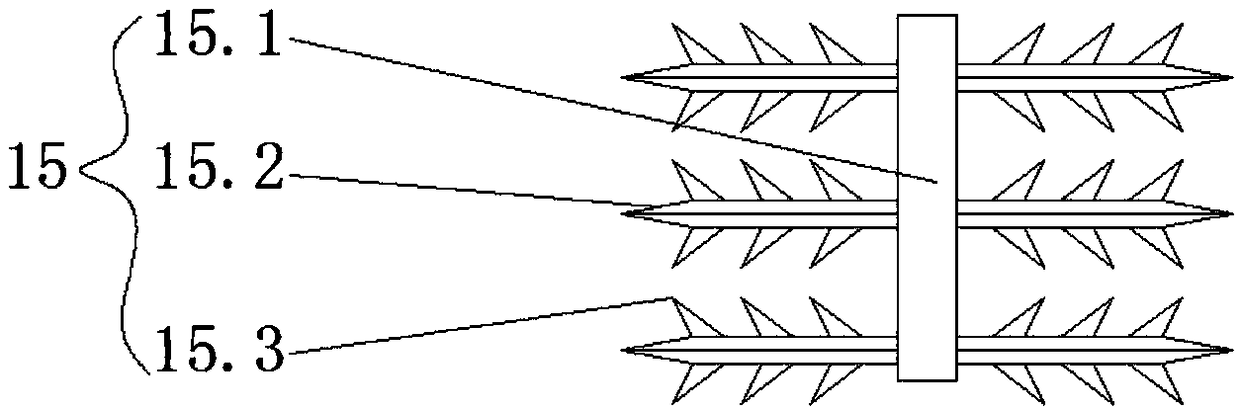

[0031] Such as Figures 1 to 2As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the crushing mechanism 15 includes a rotating shaft 15.1 connected to the coupling 14, and several stirring shafts are arranged on the rotating shaft 15.1. The upper and lower surfaces of the blade 15.2 and the stirring blade 15.2 are all provided with some serrations 15.3.

[0032] In this embodiment, the rotating stirring blade and the serrations on the stirring blade have a good crushing effect on the medical waste, and the crushing is relatively thorough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com