Fireproof air exhaust duct inlet voltage transformation flow guide device

A technology of diversion devices and exhaust ducts, applied in vertical pipes, building components, buildings, etc., can solve problems such as increasing the resistance and static pressure of exhaust ducts, reducing the exhaust force of range hoods, and affecting exhaust efficiency. To achieve the effect of unobstructed smoke exhaust, reduce smoke exhaust resistance, and improve space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

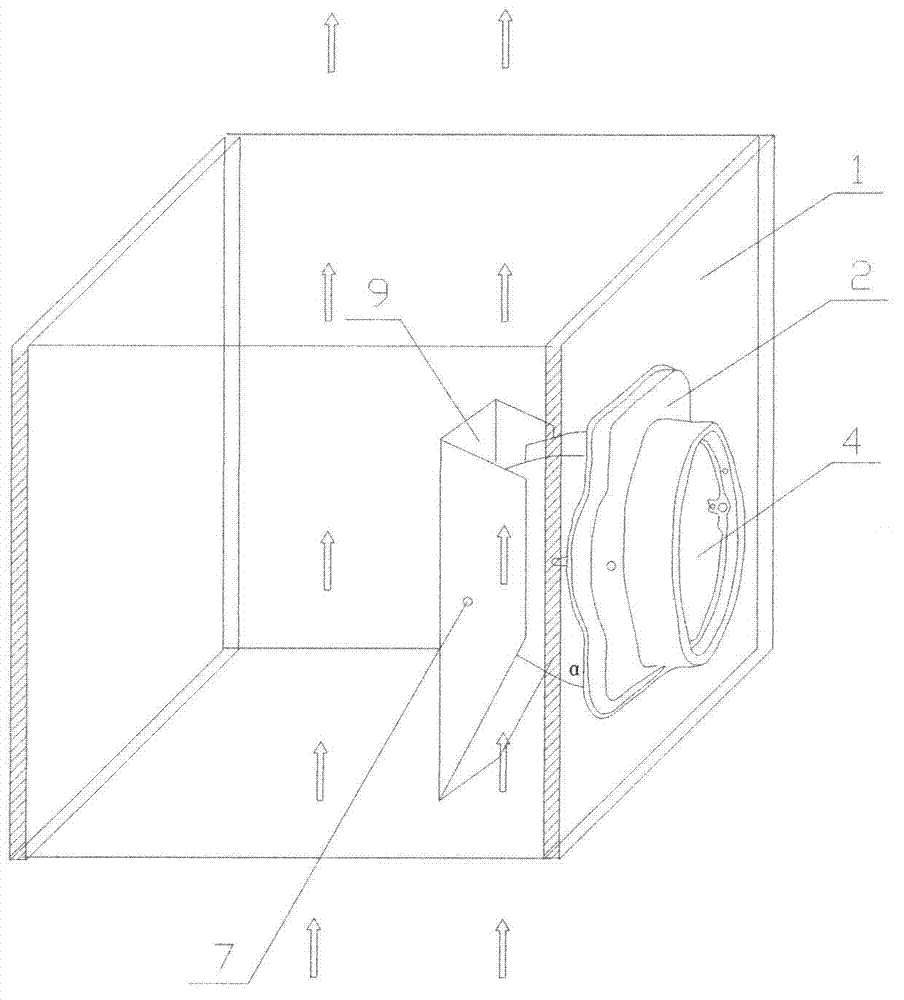

[0035] Pressure-changing diversion device at the inlet of the fire-proof exhaust duct, such as Figure 1 to Figure 4 As shown, it includes a fire check valve 2 arranged on the exhaust duct 1, and the fire check valve 2 is connected to the outer wall of the exhaust duct 1 through a connecting panel, and also includes a deflector device 9, and a right wing plate 51 and a left wing plate 52 , Deflector device 9, exhaust duct 1 inner wall, right wing plate 51 and left wing plate 52 four form a closed around, the ventilation duct that runs through up and down. The fire check valve 2 includes a valve plate 4 and an air inlet 3 .

[0036] The right wing 51 and the left wing 52 are connected to the fire check valve 2 , and the deflector device 9 is hinged to the right wing 51 and the left wing 52 through the rotating shaft 7 .

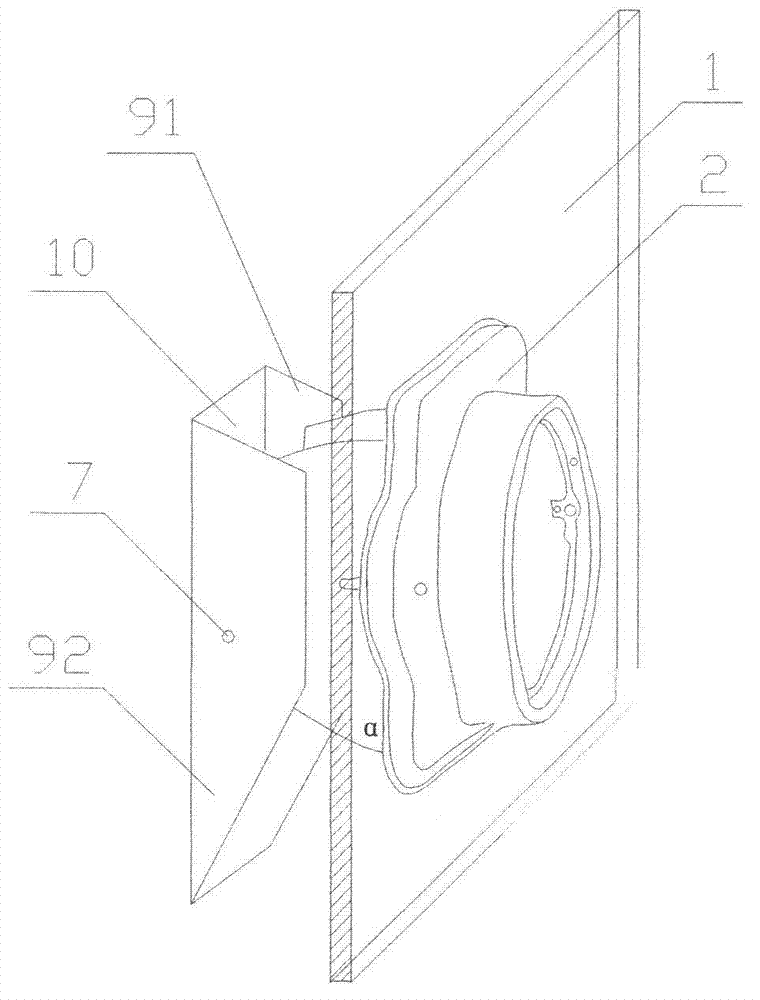

[0037] The deflector device 9 includes a right deflector 91 , a left deflector 92 and a rear deflector 10 , and the right deflector 91 and the left deflector...

Embodiment 2

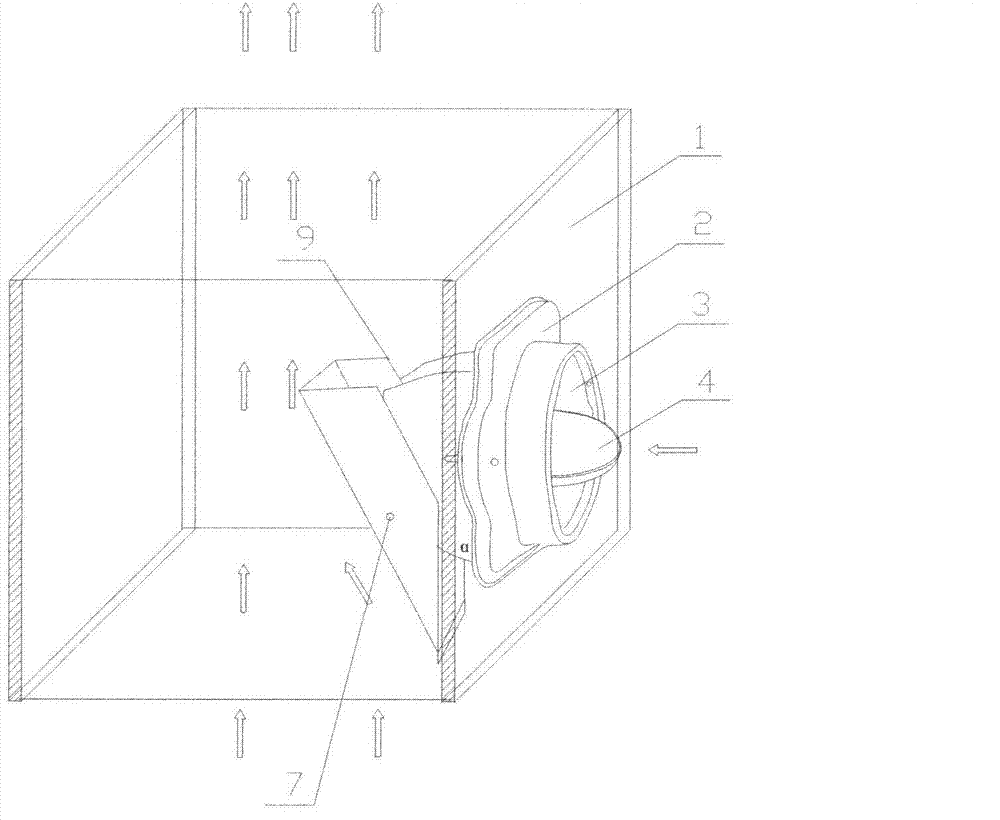

[0040] Pressure-changing diversion device at the inlet of the fire-proof exhaust duct, such as Figures 2 to 8 As shown, it includes a fire check valve 2 arranged on the exhaust duct 1, a deflector device 9, and a right wing 51 and a left wing 52, the deflector device 9, the inner wall of the exhaust duct 1, and the right wing 51 Four of the left wing plate 52 form a closed all around, the ventilation duct that runs through up and down.

[0041] The right wing 51 and the left wing 52 are connected to the fire check valve 2 , and the deflector device 9 is hinged to the right wing 51 and the left wing 52 through the rotating shaft 7 .

[0042] The deflector device 9 includes a right deflector 91 , a left deflector 92 and a rear deflector 10 , and the right deflector 91 and the left deflector 92 are respectively hinged to the right wing 51 and the left wing 52 through the rotating shaft 7 .

[0043] The height of the rotating shaft 7 is lower than the height of the horizontal midl...

Embodiment 3

[0046] Pressure-changing diversion device at the inlet of the fire-proof exhaust duct, such as Figure 9 , 10 As shown, in the present embodiment, the deflector device 9 includes a back deflector 10, the back deflector 10 is respectively hinged with the right wing plate 51 and the left wing plate 52 through the rotating shaft 7, and the lower side of the back deflector 10 is provided with a balance plate 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com