Low-noise vacuum pump

A vacuum pump, low-noise technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of increased processing and assembly difficulty, inconvenient gear disassembly and adjustment, uneven overall structure, etc., to achieve compact structure and low noise. Small, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

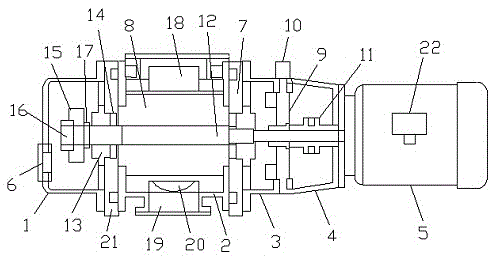

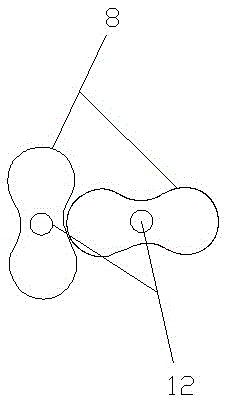

[0021] refer to figure 1 with figure 2 As shown, a low-noise vacuum pump includes a rear cover 1, a pump body 2, a front cover 3, a bracket 4 and a motor 5, and the rear cover 1, the pump body 2, the front cover 3, the bracket 4 and the motor 5 are fixedly connected in sequence , the front end of the back cover 1 is provided with a sight glass 6, the sight mirror 6 is sealed and connected with the back cover 1, and the two ends of the pump body 2 are provided with an intermediate wall 7, and the intermediate wall 7 is welded to the pump body 2, so The pump body 2 is provided with a rotor 8, the rotor 8 is provided with two, the rotor 8 is a double-leaf rotor, the front cover 3 and the bracket 4 are provided with a shaft seal 9, and the shaft seal 9 is installed There is an oil cup 10, a coupling 11 is installed at the front end of the motor 5, a main shaft 12 is arranged on the coupling 11, two main shafts 12 are provided, and shaft sleeves 13 are arranged at both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com