Electroless energy-conservation water and dust collector

A technology of equipment and vacuum tubes, which is applied in the field of non-electric water suction and vacuum equipment, can solve the problems of no water absorption function, potential safety hazards, low vacuum degree, etc., achieve reduced maintenance costs, simple structure, and improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Adopt a preferred example below in conjunction with accompanying drawing to further illustrate this technical scheme:

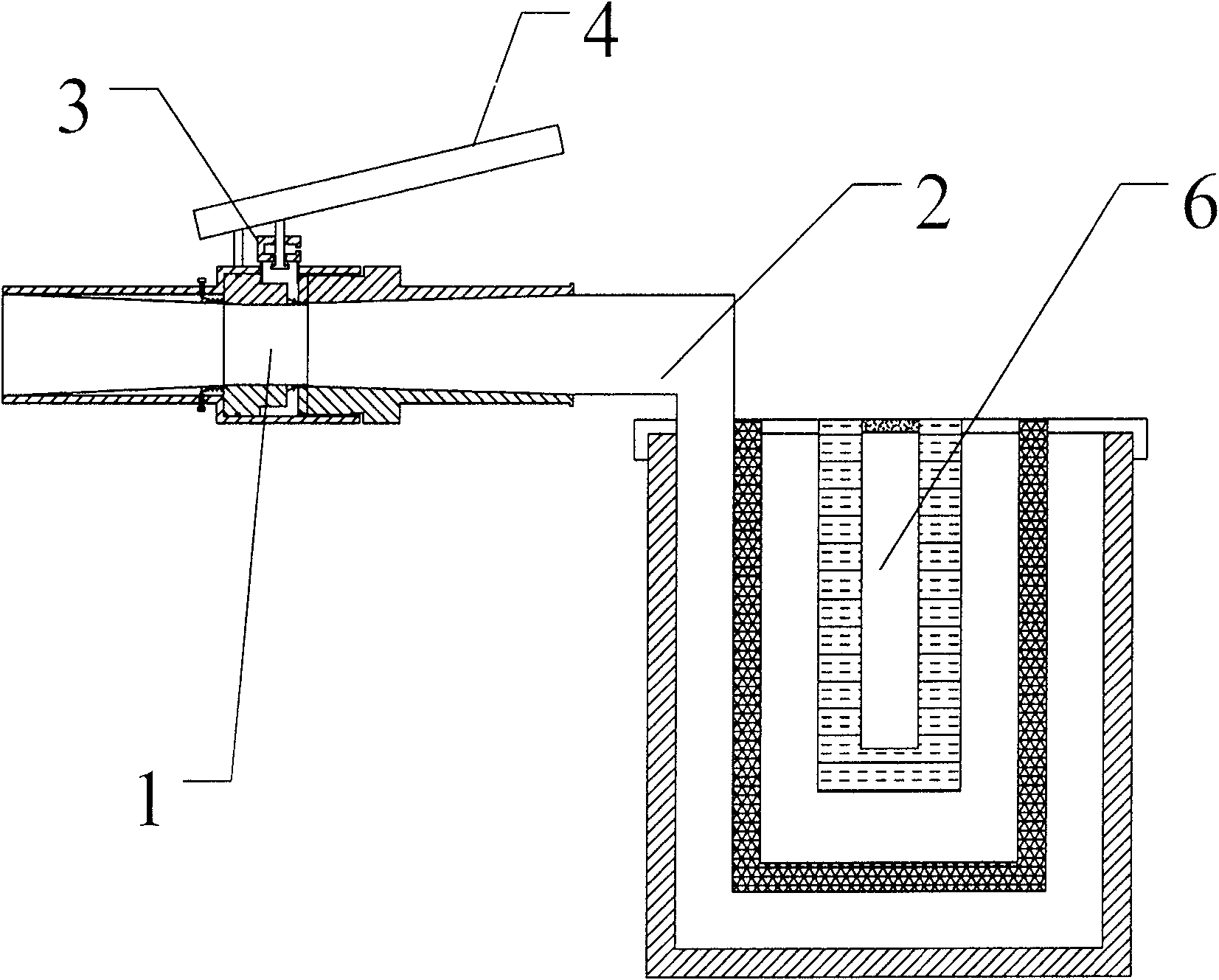

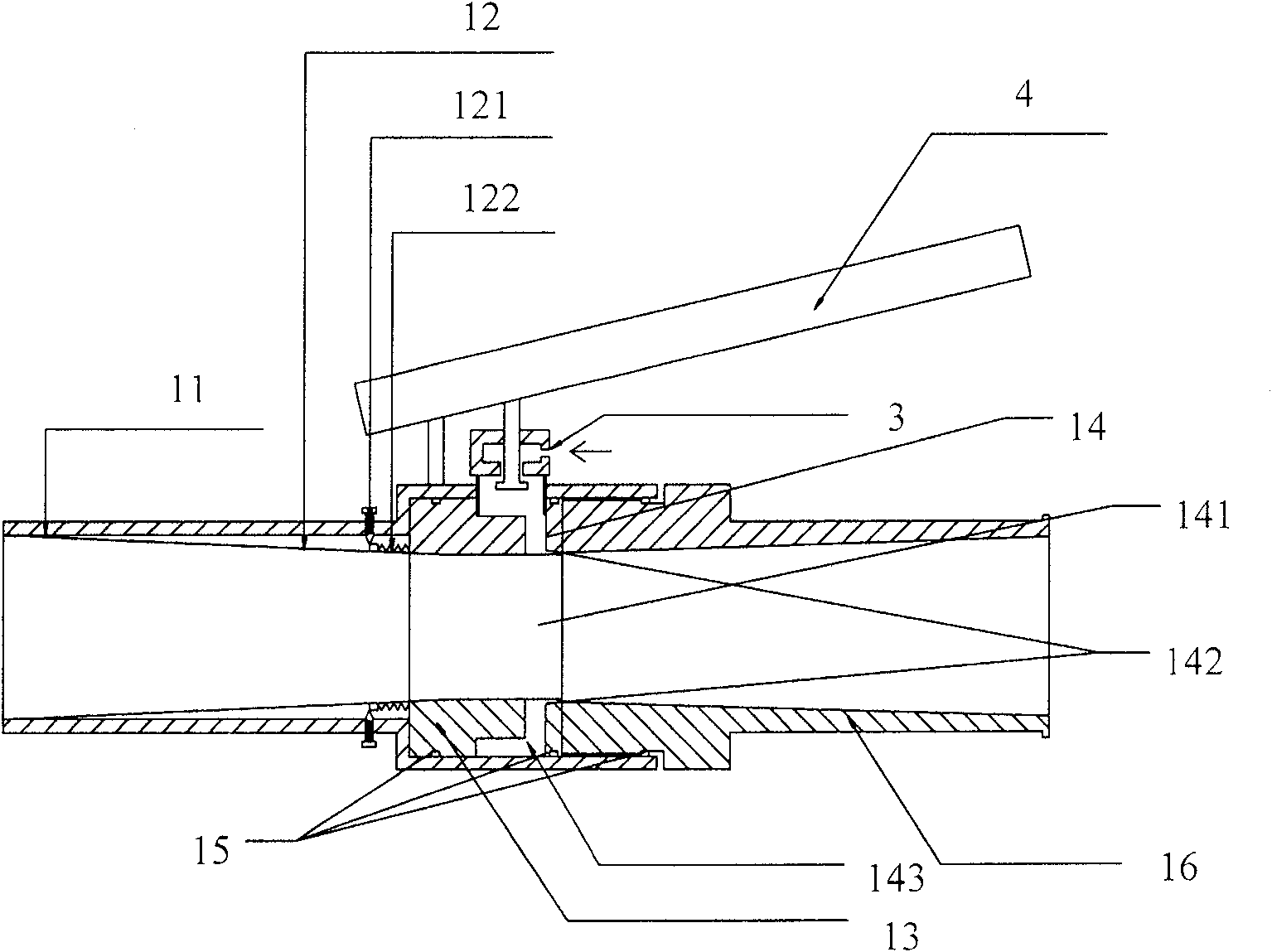

[0027] The non-electric energy-saving dust-absorbing and water-absorbing equipment described in the technical solution includes an integrated non-electric water-absorbing and dust-absorbing main body 1, a dust discharge connecting pipe 2, an air intake switch 3, an air intake switch handle 4 and a dust collection box 6.

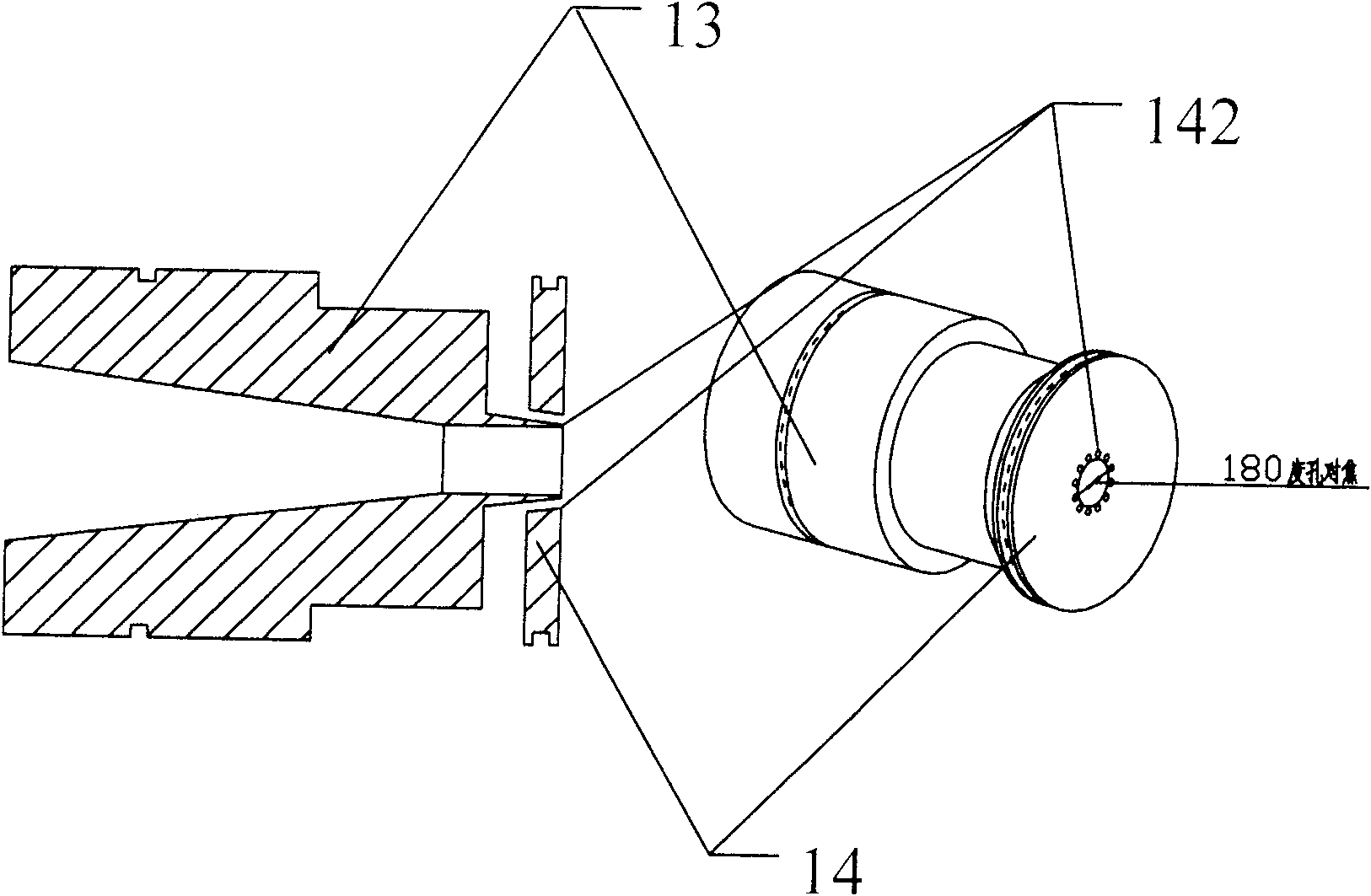

[0028] The integrated non-electric water-absorbing and dust-absorbing main body 1 mainly includes a front-section Venturi vacuum tube shell 11, a variable front-section Venturi tube body 12, a front-section Venturi vacuum tube connector 13, and a honeycomb integrated Venturi exhaust tube. Device 14, sealing ring 15, rear end Venturi dust discharge pipe body 16. The front Venturi dust suction pipe shell 11 and the rear Venturi dust discharge pipe body 16 are combined to form the shell of the integrated non-electric water-absorbing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com