Noise insulating cover of power system

A technology of power system and sound insulation cover, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of long-term hazards of high-decibel noise for operators, achieve good heat dissipation effect, ensure normal operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] see Figure 1~5 The present invention will be further described below in conjunction with embodiment.

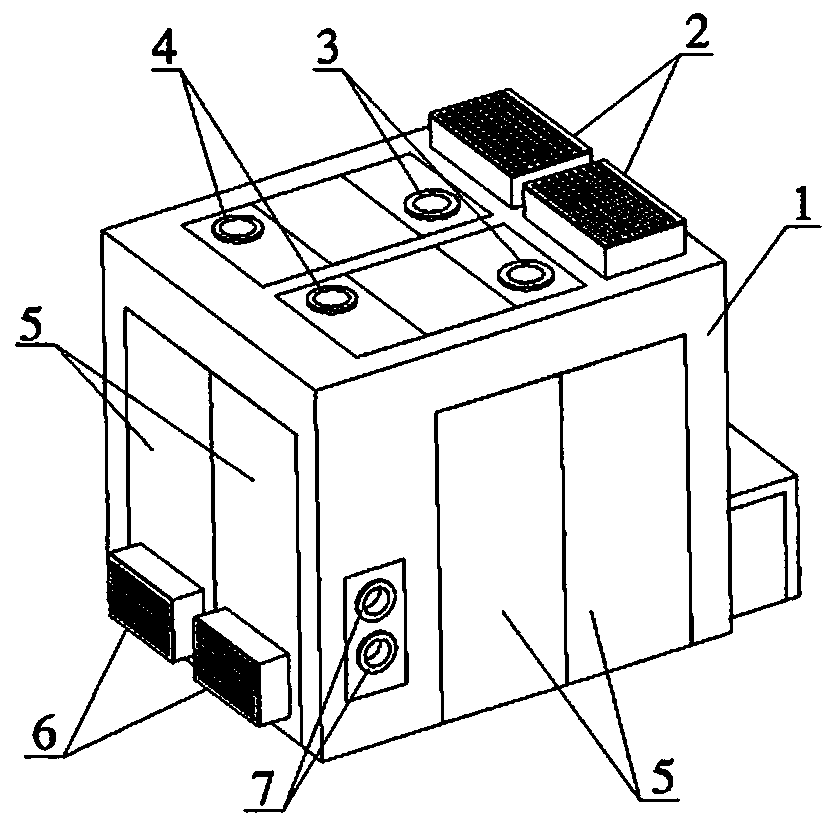

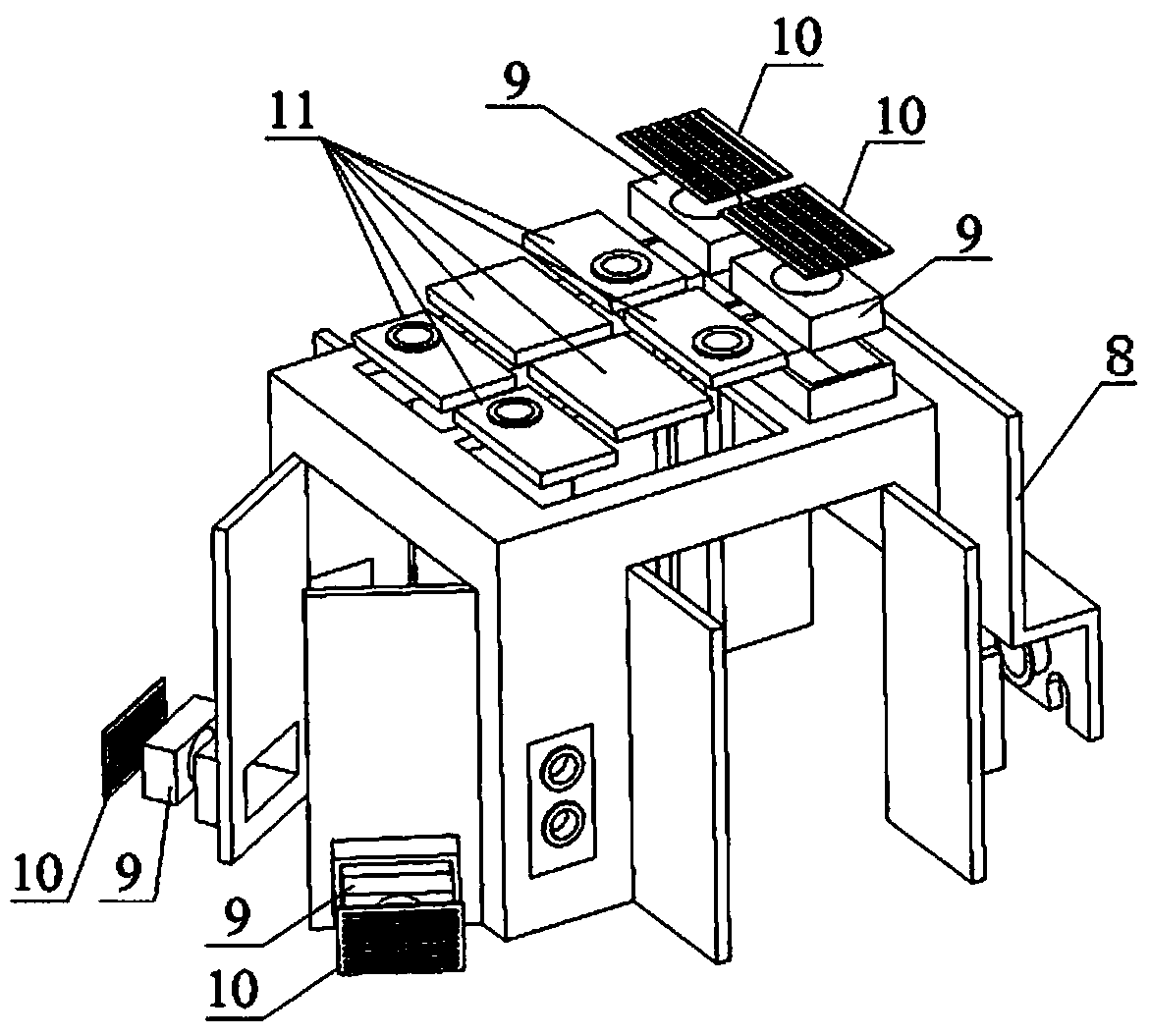

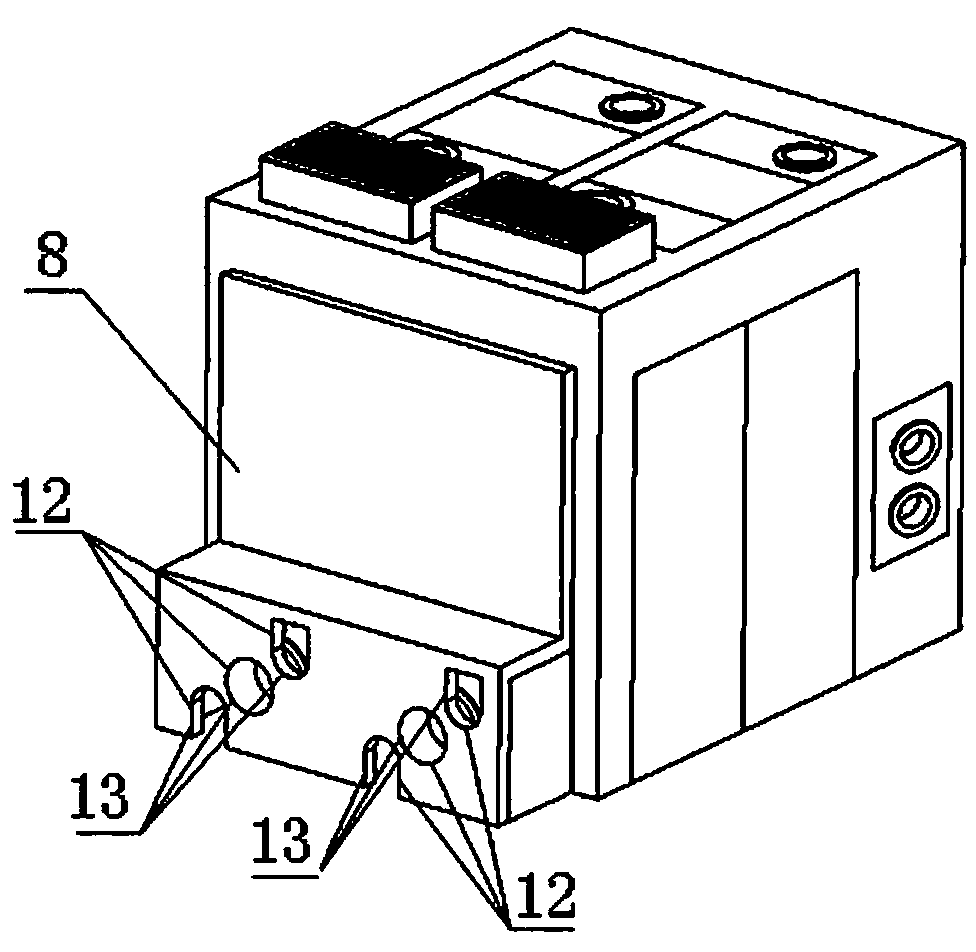

[0022] A noise treatment device, especially a power system soundproof cover, comprising a body 1 for sealing the power system and a side door 5 arranged on the side of the body 1, characterized in that: the body 1 is arranged with a ventilation system, The ventilation system has a movable sound insulation device matched with the side of the main body, and the movable sound insulation device is provided with a power interface 13 .

[0023] When working, the cover body 1 is installed on the bottom foundation of the equipment with plastic seals using connecting components, the movable sound-absorbing panel 11 is fastened, the side door 5 is closed, the movable sound insulation wall 8 is closed, and the power system of the equipment is closed. The noise generated by the power system in the body 1 absorbs the direct sound through the body 1, reduces the reverberation soun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com