Preparation method of multilayer metal grating

A multi-layer metal and grating technology, which is applied in the direction of diffraction grating, optical mechanical equipment, photo-plate making process of pattern surface, etc., can solve the problems of difficult precise control of metal distribution, low optical efficiency, high equipment requirements, etc., and achieve cost Low cost, simple process, and the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

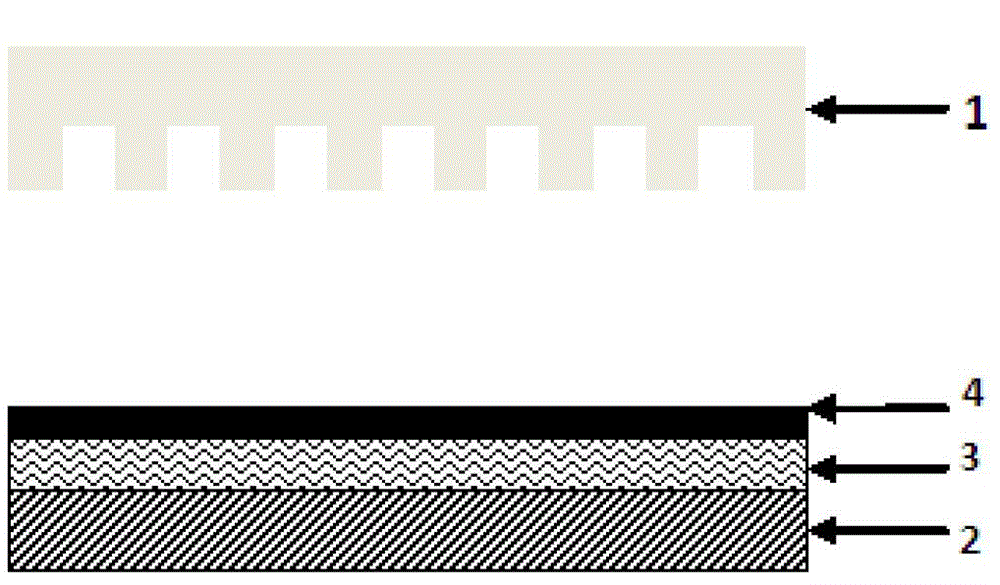

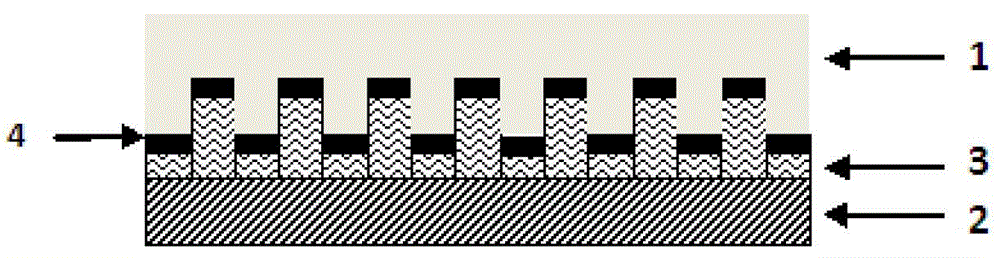

[0032] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solutions of the present invention, and provides detailed implementation methods and specific operation processes. For the convenience of illustration, the thickness of the layer is enlarged or reduced in the figure, and the shown size and ratio do not represent the actual situation. The embodiments of the present invention should not be considered limited to the specific properties of the regions shown in the figures, and periodic grating structures are used in the embodiments to illustrate, but this should not limit the protection scope of the present invention.

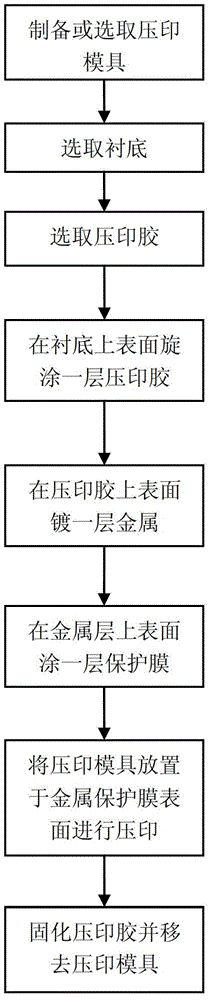

[0033] As shown in the figure, it specifically includes the following steps:

[0034] Step 1) Prepare or select an imprint template 1, the material is silicon nitride, the pattern is a grating with a rectangular cross section, the period is 200nm, the depth is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com