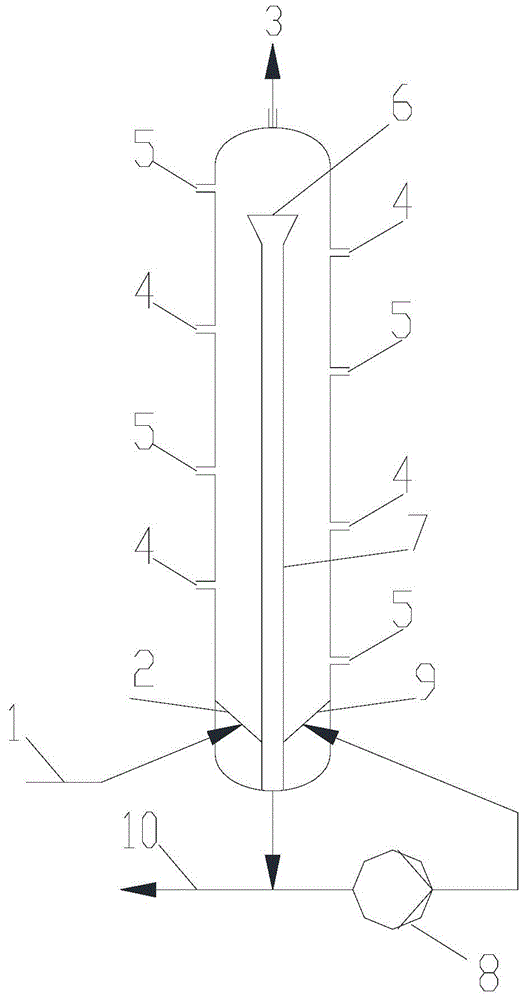

Multi-optimized slurry bed hydrogenation reactor, application and design method thereof

A hydrogenation reactor and slurry bed technology, applied in chemical instruments and methods, chemical/physical processes, hydrocarbon oil cracking, etc., can solve problems such as blockage and coking, reduce costs, speed up reaction rates, and deepen reaction levels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example is an example of residual oil hydrogenation. The structural parameters of the reactor are as follows: the inner diameter of the reactor shell is 200mm, the height of the reactor shell is 3500mm, the diameter of the reactor circulation pipe is 80mm, and the height is 3200mm. Using FeOOH iron-based catalyst and the above-mentioned slurry bed hydrogenation reactor, heavy oil hydrogenation test was carried out under the slurry bed process conditions with the following basic parameters. The properties of the residual oil used in the test are shown in Table 1.

[0038] The basic process parameters of the pilot slurry bed:

[0039] Temperature: 440-460°C;

[0040] Experimental pressure: 17-19Mpa;

[0041] Hydrogen oil ratio: 900:1-1000:1;

[0042] Airspeed: 0.5h -1 ;

[0043] Circulation volume / feed volume: 4.0;

[0044] Catalyst / feed residue: 1 / 100(wt);

[0045] Vulcanizing agent / feed residue: 2.5 / 100 (wt).

[0046] The results of the test are as follows:

...

Embodiment 2

[0051] This embodiment is an example of direct coal liquefaction. The reactor used is the same as in Example 1, and the catalyst is the same as in Example 1. Under the pilot test slurry bed process conditions with the following basic parameters, the direct coal liquefaction test is carried out. The pulverized coal used in the test See Table 2 for the properties, and the basic process parameters of the pilot slurry bed are as follows:

[0052] Temperature: 440-465°C;

[0053] Experimental pressure: 17-20Mpa;

[0054] Hydrogen oil ratio: 1200:1~1600:1;

[0055] Airspeed: 0.35~0.50h -1 ;

[0056] Circulation volume / feed volume: 6.0;

[0057] Mass ratio of oil / coal feed / circulating solvent: 10:10:1;

[0058] Catalyst / feed coal: 1.2 / 100(wt);

[0059] Vulcanizing agent / feed coal: 2.5 / 100(wt);

[0060] Slurry bed chemical hydrogen consumption (hydrogen / feed): 5 / 100 (wt).

[0061] The results of the test are as follows:

[0062] Coal conversion rate: 88.2%, liquid yield 58.3%...

Embodiment 3

[0067] This embodiment is an example of oil-coal mixing, the reactor structure is the same as Example 1, the catalyst is the same as Example 1, the properties of the residual oil used in the test are the same as Example 1, and the properties of coal powder are the same as Example 2. The basic process parameters of the pilot test slurry bed in the present embodiment are as follows:

[0068] Temperature: 440-460°C;

[0069] Experimental pressure: 17-20Mpa;

[0070] Hydrogen oil ratio: 1000:1-1400:1;

[0071] Airspeed: 0.40-0.50h -1 ;

[0072] Circulation volume / feed volume: 5.0;

[0073] Oil / coal feed / refined wax oil mass ratio: 9:10:2;

[0074] Catalyst / feed oil coal slurry: 1 / 100(wt);

[0075] Vulcanizing agent / feed oil coal slurry: 2.5 / 100(wt);

[0076] Slurry bed chemical hydrogen consumption (hydrogen / feed): 4.5 / 100 (wt).

[0077] The results of the test are as follows:

[0078] Total conversion rate of oil and coal: 91.2%, liquid yield 71.3%, coke production rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com