Method and device for reversely cyclically producing and lifting pump core of hydraulic jet pump

A hydraulic injection and reverse circulation technology, applied in jet pumps, wellbore/well valve devices, pumps, etc., can solve problems such as increased production costs, troublesome site management and operations, and increased operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

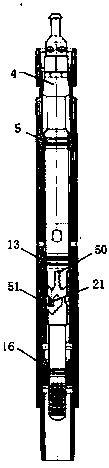

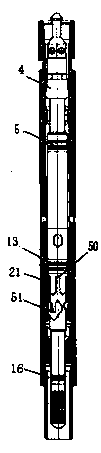

[0045] A pump core device of a reverse circulation production and reverse circulation hydraulic jet pump, which is characterized in that it contains a pump core and a work cylinder;

[0046] 2. The structure of the pump core and working cylinder:

[0047] (1) Pump core:

[0048] There is a fishing head body 1 from top to bottom: the upper 1 / 3 of the fishing head body 1 is a solid rod with an outer diameter of 20mm, the top is a fishing head, and the section of the middle 1 / 3 part is a 52mmx52mm quadrilateral, and the four sides face the center Drill four holes obliquely, the lower 1 / 3 is cylindrical with a diameter of 52mm, the inner part is a long hole with a diameter of 30mm and communicates with the four oblique holes in the middle and upper part, and the lower end of the inner hole is an internal thread;

[0049] Pump rubber cylinder 3: It is made of oil-resistant rubber, and the maximum outer diameter is 60mm. It is a tapered rubber cylinder with a central through hole, ...

Embodiment 2

[0076] A method of reverse circulation production and reverse circulation hydraulic jet pump pump core, using reverse circulation, that is, the power fluid is injected from the casing, and the formation fluid is returned to the ground from the oil pipe to be transported out; the ground water injection pipe network is used as the power fluid, After flowing through the nozzle, it forms a high-speed jet with the formation fluid, passes through the diffusion zone of the throat pipe, and then enters the upper oil pipe of the pump.

[0077] Including the steps of running the pipe string in the casing, lowering the pump core, reverse circulation production and reverse circulation pump core;

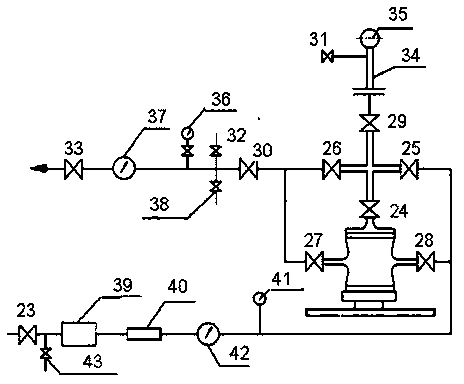

[0078] Step A. Run the pipe string in the casing: the pipe string structure is from bottom to top: 2 7 / 8 "Oil pipe plus dead plug, liquid inlet screen, 2 7 / 8 "Oil pipe, check valve, packer, safety joint, work cylinder for reverse circulation (washing) pump core during reverse circulation,...

Embodiment 3

[0084] A reverse circulation production and reverse circulation hydraulic jet pump pump core method, including the steps of running a pipe string in the casing, lowering the pump core, reverse circulation production and reverse circulation pump core;

[0085] Taking a reverse circulation production and reverse circulation method for the pump core of a hydraulic jet pump as an example, the present invention is further described in detail:

[0086] E.g:

[0087] (1) Geological requirements for a well:

[0088] ①The production section of this well is long (141.01m), and the fluid volume is lower than that of adjacent wells. The well’s daily fluid production: 18.7m3, and daily oil production: 6.2t. One adjacent well: daily liquid production: 61.4m3, daily oil production: 32.1t, another adjacent well: daily liquid production: 42m3, daily oil production: 8.5t.

[0089] ② It is recommended to implement acid washing to remove plugging of the well. A section of acidified sand has 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com