Hydraulic jet pump capable of realizing reverse-circulating production and reverse-circulating lifting of pump core

A hydraulic injection and reverse circulation technology, applied in jet pumps, pumps, non-displacement pumps, etc., can solve the problems of site management and operation troubles, complex downhole string structure, increased workload, etc., and achieve the effect of mechanical impurities deposition Good, reduce the risk of overhaul and scrapping, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and cannot limit the protection scope of the present invention.

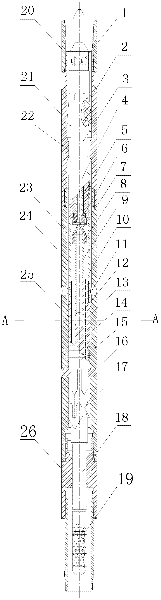

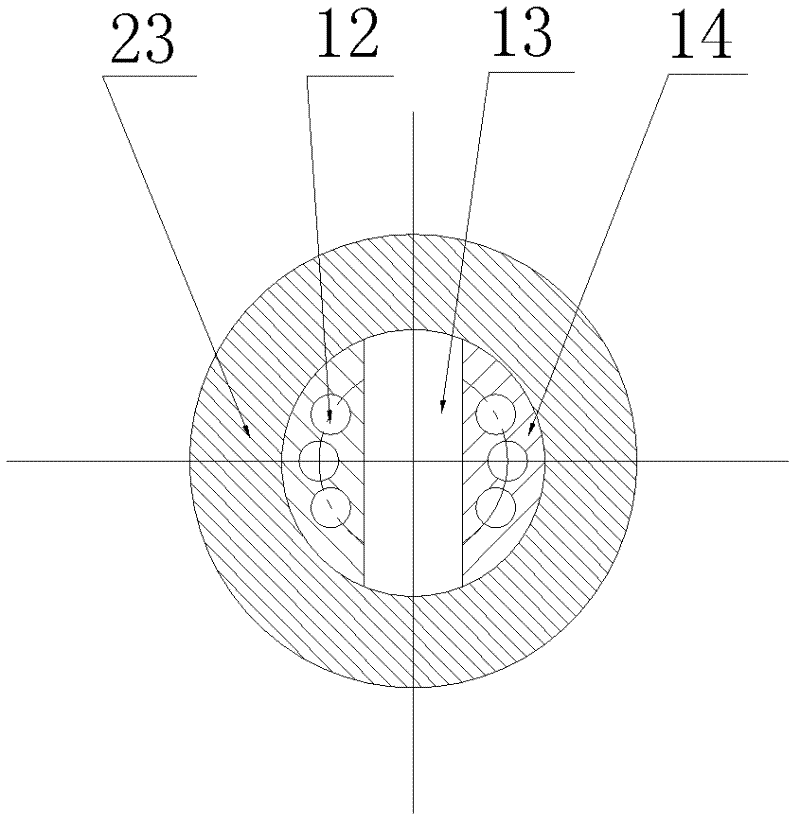

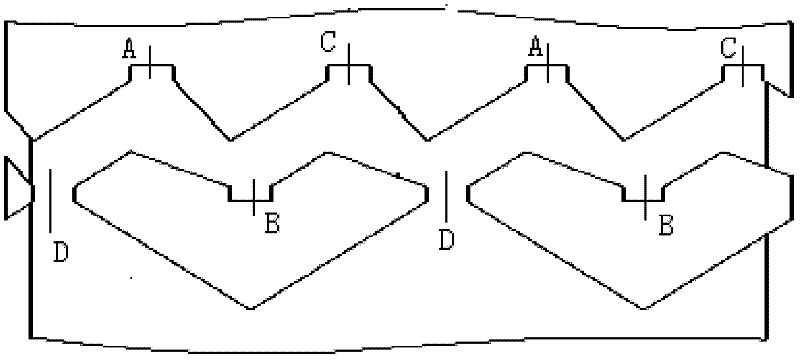

[0021] A reverse circulation production, reverse circulation pump core hydraulic jet pump, consisting of a working cylinder and a pump core. The working cylinder includes an upper joint 20, an upper sealing sub-section 22, a main cylinder body 23 and a lower joint 26, and the upper sealing sub-section An upper high-pressure sealing ring sealing surface 21 is made on the inner wall, a lower high-pressure sealing ring sealing surface 25 is made on the lower part of the main cylinder, and a working cylinder liquid inlet 11 is made on the upper part of the main cylinder. The pump core includes an overshot body 1 connected in sequence. , Pump rubber cylinder 2, upper connection sub 3, pump cylinder 10, high and low pressure dividing sub section 14, lower connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com