Roll-type membrane element

A roll-type membrane and element technology, applied in membrane technology, semi-permeable membrane separation, osmosis/dialysis water/sewage treatment, etc., can solve the problems of reverse osmosis membrane blockage, waste, long length of produced water flow channels, etc., and achieve extended use. The effect of long life, high flow speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

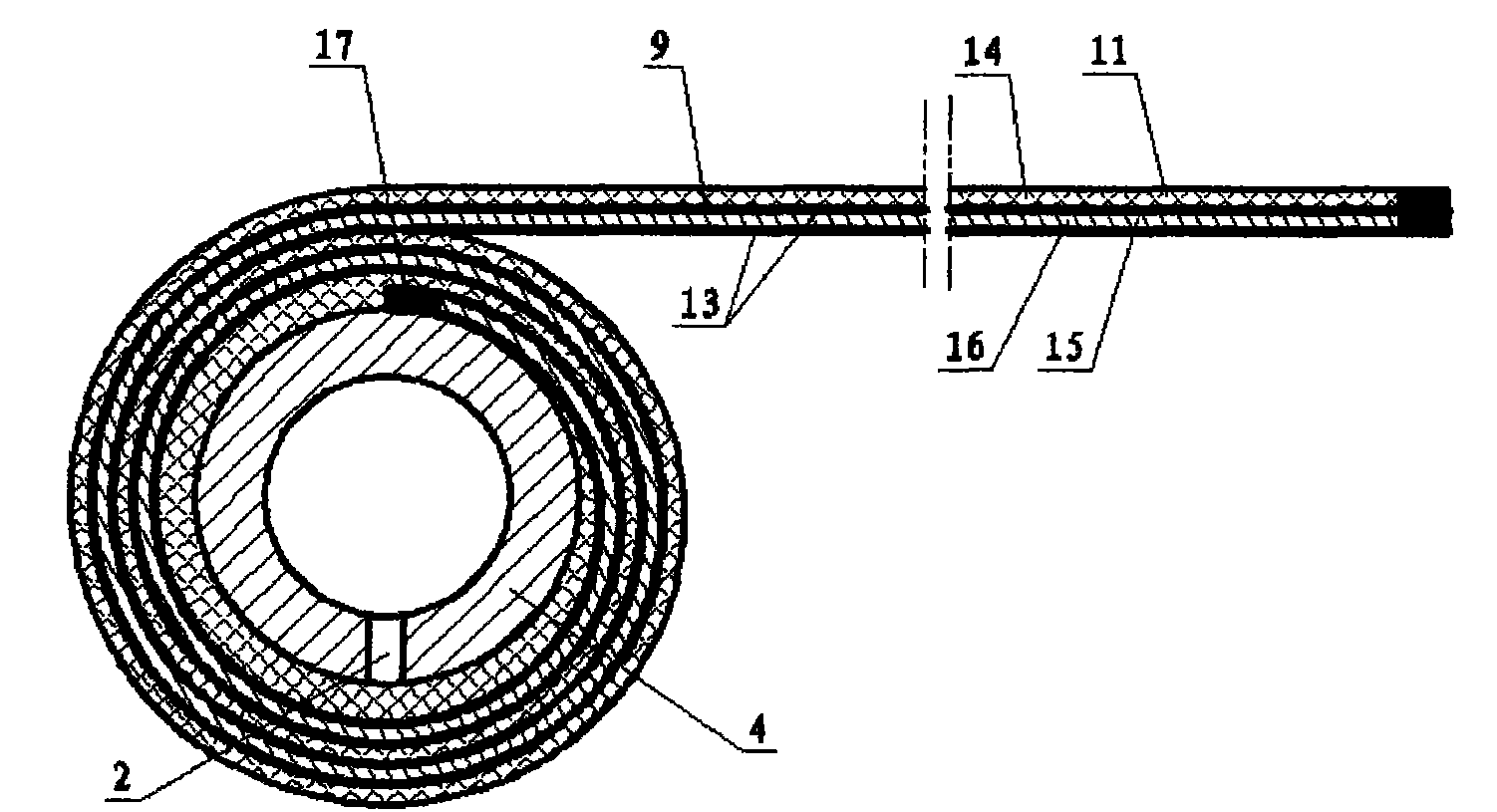

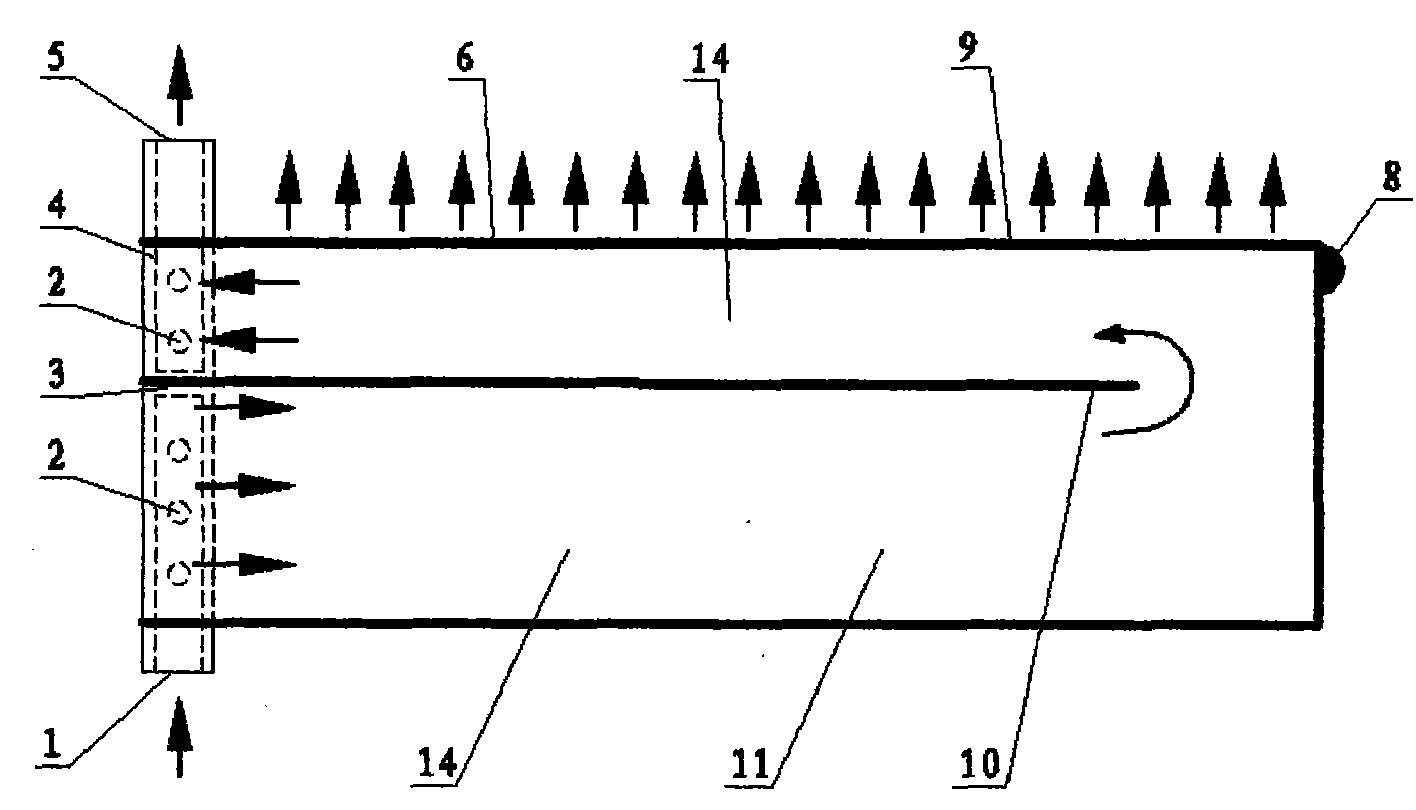

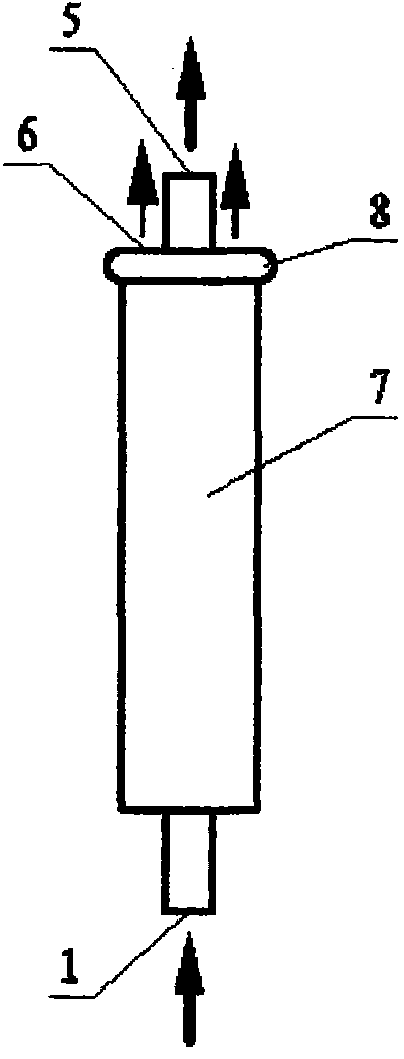

[0041] See Figure 1 to Figure 3 , the coiled membrane element of the present embodiment includes a central tube 4, a water purification membrane group 9 and a flow guide strip 10; the water purification membrane group 9 is wound on the central tube 4; the water purification membrane group 9 It includes a raw water diversion net 11, two sheet-shaped high-precision filter membranes 13 and a product water diversion net 15, and the product water diversion net 15 is arranged between the two sheet-like high-precision filter membranes 13. It is the produced water flow channel 16; one side of the sheet-shaped high-precision filter membrane 13 is adjacent to the raw water flow channel 14, and the other side is adjacent to the produced water flow channel 16; the raw water diversion network 11 is arranged in the raw water flow channel 14, and the The product water diversion net 15 is arranged in the water production channel 16; the diversion strip 10 is arranged in the raw water flow ch...

Embodiment 2

[0045] See Figure 4 and Figure 5 , the roll-type membrane element of this embodiment is basically the same as that of Embodiment 1, the difference is that: the raw water diversion net 11 is arranged between two sheet-like high-precision filter membranes 13, and after the raw water flow channel 14 is unfolded, the guiding net 11 therein The flow bar 10 is not perpendicular to the axis of the central pipe 4, and the flow guide bar 10 is in a spiral shape in the coiled membrane element, and it is in a manner that can make the width of the raw water flow channel 14 gradually decrease along the water flow direction. It is arranged obliquely; two sheet-shaped high-precision filter membranes 13 are formed by folding a large high-precision filter membrane 13, and the folded edge is wound in the rolled membrane element, and the folded edge is the edge of the raw water flow channel 14. One side of the seal is closed, and the side is perpendicular to the axis of the central tube 4 aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com