Pipeline type multistage oil-water separator utilizing angular momentum conservation

A technology of conservation of angular momentum and oil-water separator, which is applied in the field of downhole oil-water separation devices, can solve the problems of limited separation efficiency, small processing capacity, and large volume, and achieve the effects of improving separation efficiency, high-efficiency separation, and compensating for tangential velocity attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in more detail below in conjunction with accompanying drawing example:

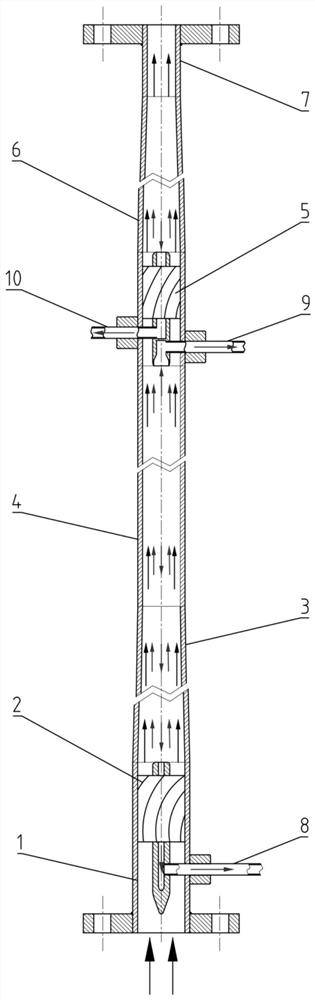

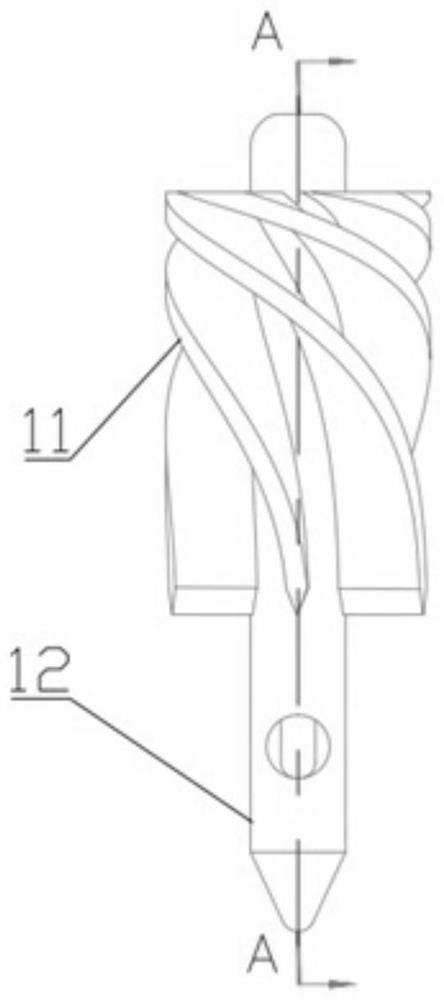

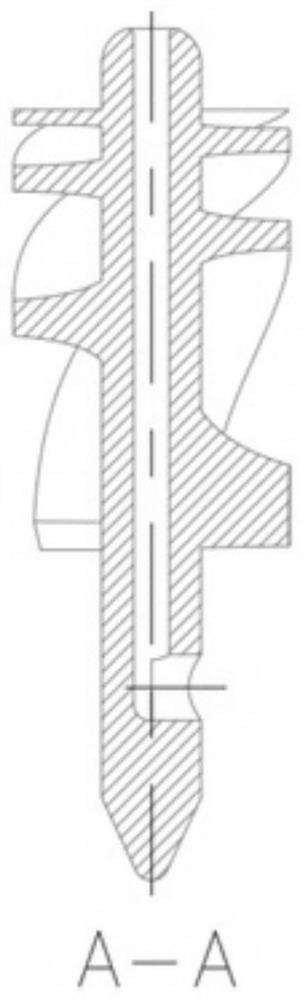

[0027] combine Figure 1-3b , a combined multi-flow fine gas-liquid separator provided by the present invention, comprising: an inlet section 1, a first-stage impeller 2, a first-stage tapered section 3, a first-stage separation section 4, a second-stage impeller 5, and a second-stage Taper section 6, secondary separation section 7, primary oil inlet 8, secondary oil inlet 9, third-stage oil inlet 10, primary blade 11, primary axle 12, secondary blade 13, secondary axle 14.

[0028] The outer diameter of the first-stage impeller 2 is fixed in the inlet section 1, and the downstream end of the first-stage impeller 2 is aligned with the downstream end of the inlet section 1; The end of the narrower section 3 with a larger inner diameter is connected to the inlet section 1, and the end with a smaller inner diameter is connected to the primary separation section 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com