Liquefied gas combustion chamber with outlet equipped with swirling vanes

A swirl vane and combustion chamber technology, applied in the field of liquefied gas combustion chamber, can solve problems such as poor heat exchange uniformity and high heat load, and achieve the effects of simple structure, reduced thermal shock, and wide fuel expansibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

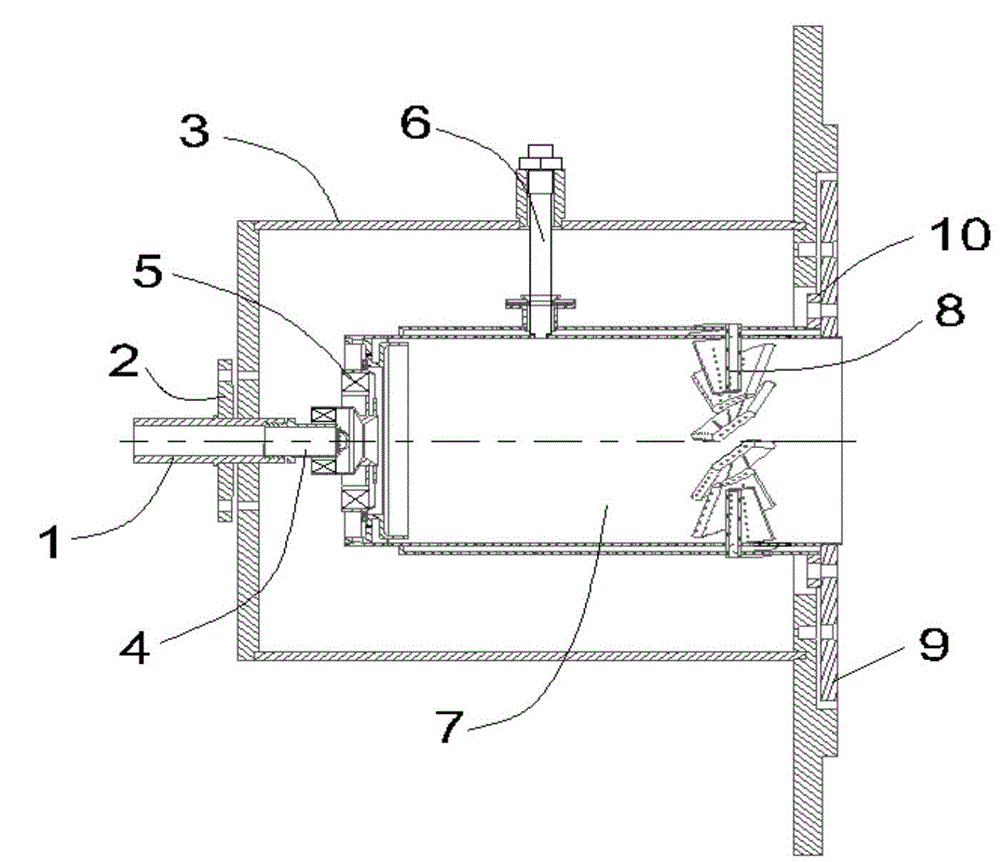

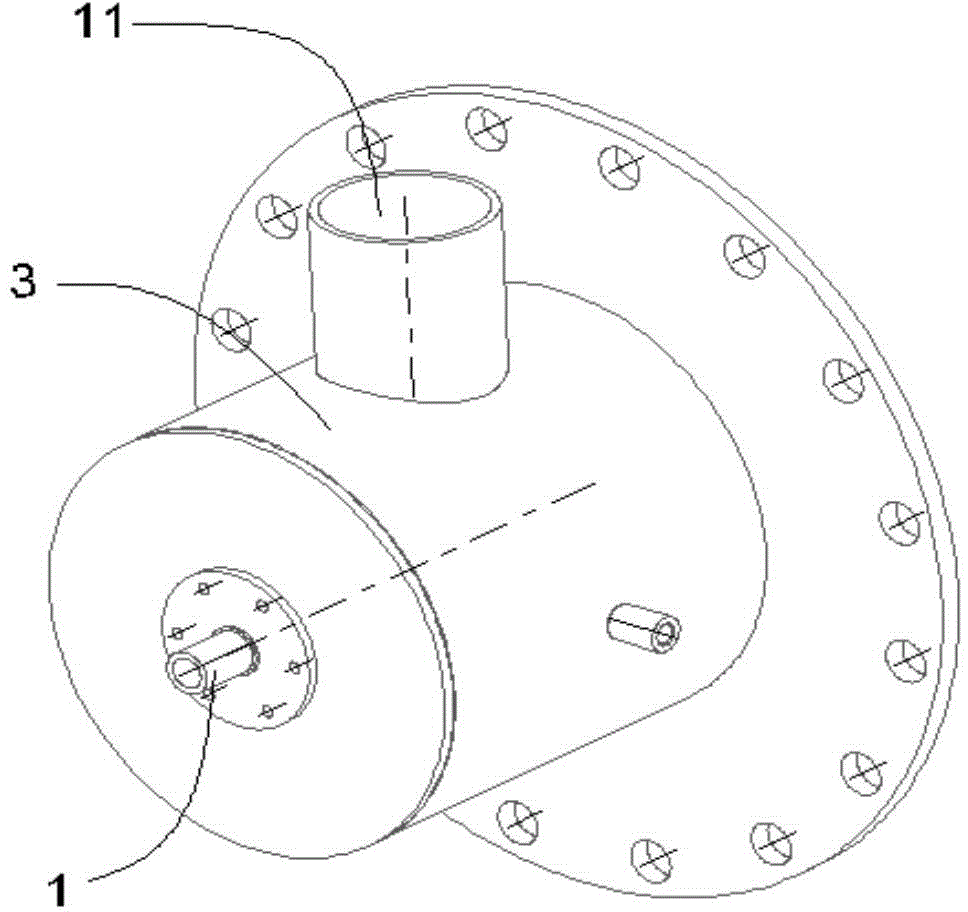

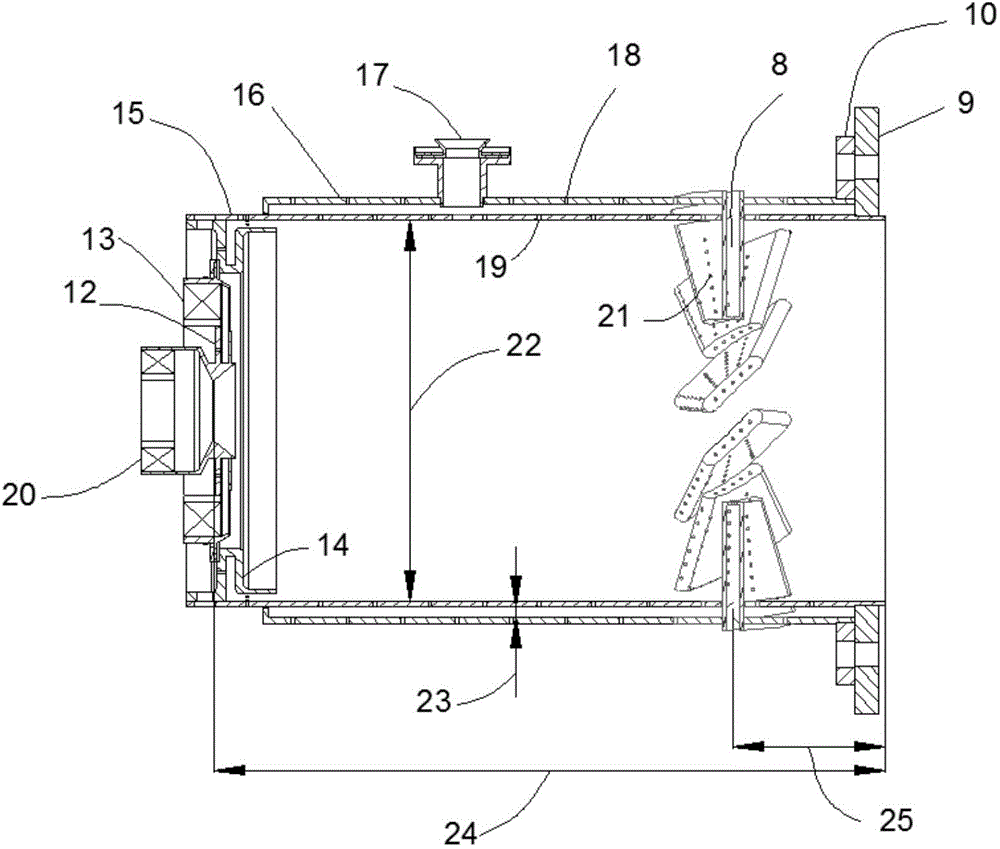

[0030] Such as Figure 1-7 As shown in this embodiment, a liquefied gas combustion chamber with swirling blades at the outlet adopts a single-tube cylindrical combustion chamber structure, and the whole is made of stainless steel. And swirl blade 8 constitutes. The liquefied gas fuel enters the head of the combustion chamber through the oblique small hole of the nozzle 4. Air enters the combustion chamber from the air inlet 11 of the combustion chamber, and part of the air enters the combustion chamber from the inner swirler 20 and the outer swirler 13 to directly participate in combustion, and the swirl generated by the inner swirler 20 completes the mixing with the liquefied gas. The swirl created by the outer swirler 13 forms a recirculation zone to stabilize the flame. Part of the air enters the flame cylinder from the impact wall 16, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com