Swirling piece, swirling burner and manufacturing method of swirling burner

A swirl burner and manufacturing method technology, applied in the direction of combustion method, burner, gas fuel burner, etc., can solve the problem of large pressure loss, achieve the effects of stable flow, simplify the installation process, and alleviate noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

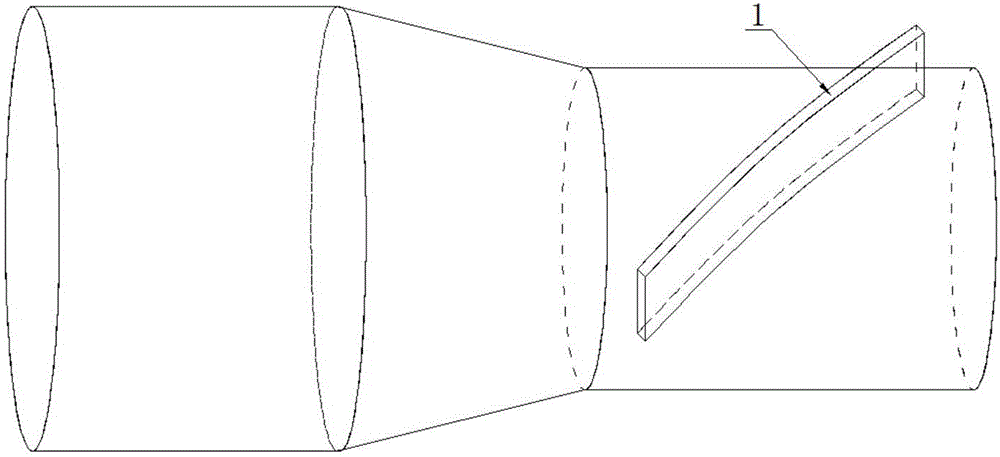

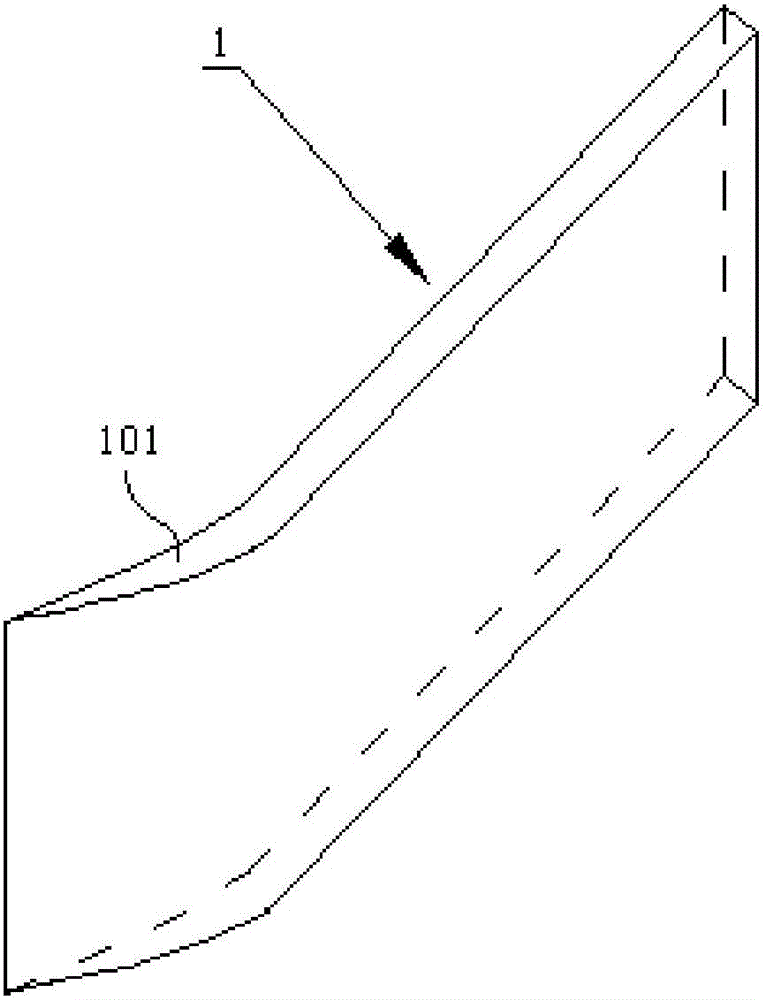

[0043] refer to figure 2 , the swirl sheet 1 of the present embodiment comprises a swirl sheet body, one end of the swirl sheet body is provided with a windward section 101, and the other end is provided with a windward section 102, and the fluid flows from the windward section 101 to the windward section 102; The thickness of the segment 101 gradually increases along the flow direction of the fluid until it is the same as the thickness of the swirl vane body.

[0044]Most of the swirl combustion equipment in the prior art uses the swirl generated by the swirl sheets to enhance the combustion effect, but the swirl sheets produced in the prior art can guide the fluid, especially the high-speed flowing fuel or air , The pressure loss is large, which not only increases the power consumption of the blower, but also affects the efficiency of the burner. In the prior art, it is generally believed that the mechanism of high pressure loss after the high-speed fluid passes through th...

Embodiment 2

[0047] refer to figure 2 , the structure of the swirl sheet 1 of the present embodiment is basically the same as that of embodiment 1, the difference is that in the design process, the ratio between the length of the windward section 101 and the length of the entire swirl sheet should be adjusted, the present embodiment Among them, the length of the windward section 101 is 0.05 to 0.9 times the length of the entire swirl vane, so as to adapt to different design conditions (specifically, 0.05 is taken in this embodiment); theoretically, the windward section 101 is far away from one end of the swirl vane body. The thinner the thickness, the better the diversion effect of the high-speed fluid, and the more it can reduce the impact pressure drop of the high-speed fluid. However, in the actual processing of the swirl sheet in this embodiment, the thickness of the windward section 101 away from the end of the swirl sheet body can be designed. It is 0.01 to 0.25 times the thickness ...

Embodiment 3

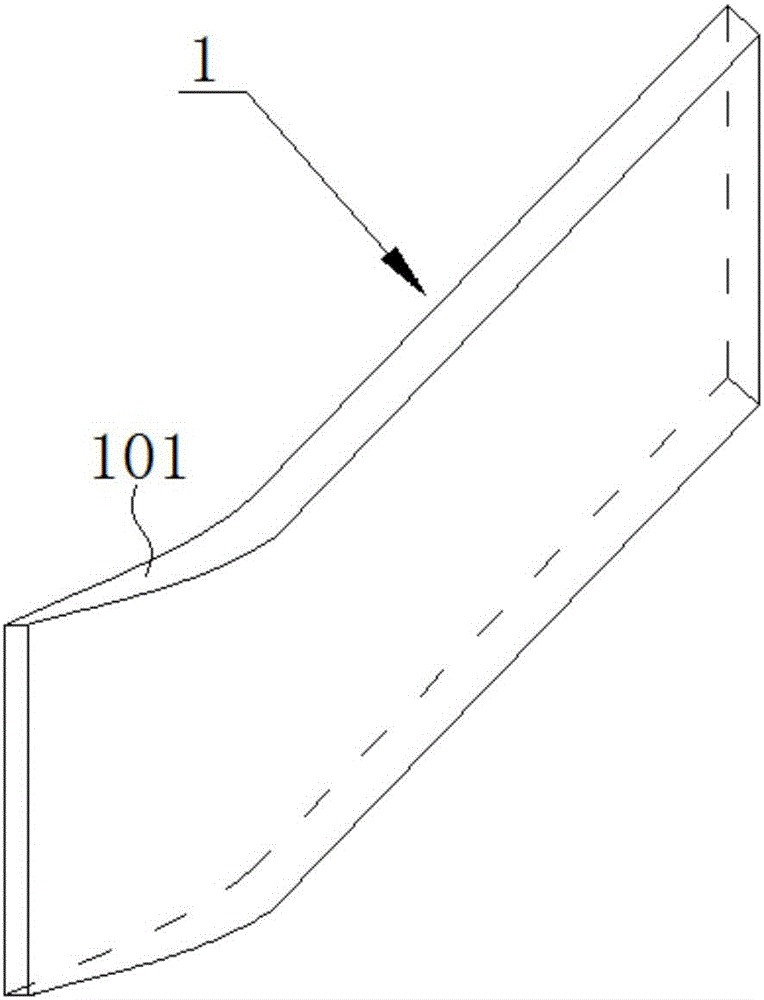

[0049] refer to Figure 4 , the structure of the swirl sheet 1 of the present embodiment is basically the same as that of embodiment 2, the difference is that the thickness of the contact between the air outlet section 102 and the swirl sheet body is the same as the thickness of the swirl sheet body, and the air outlet section The thickness of 102 tapers in the direction of fluid flow.

[0050] In this embodiment, the thickness of the air outlet section 102 is designed to be tapered along the flow direction of the fluid, so that when the high-speed fluid flows out along the air outlet section 102, it forms a good guiding effect on the outflowing high-speed fluid, and enhances the final formation of swirling flow. stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com