Pilot differential valve with metering function

A pilot-operated, valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of large volume and weight, unacceptable and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

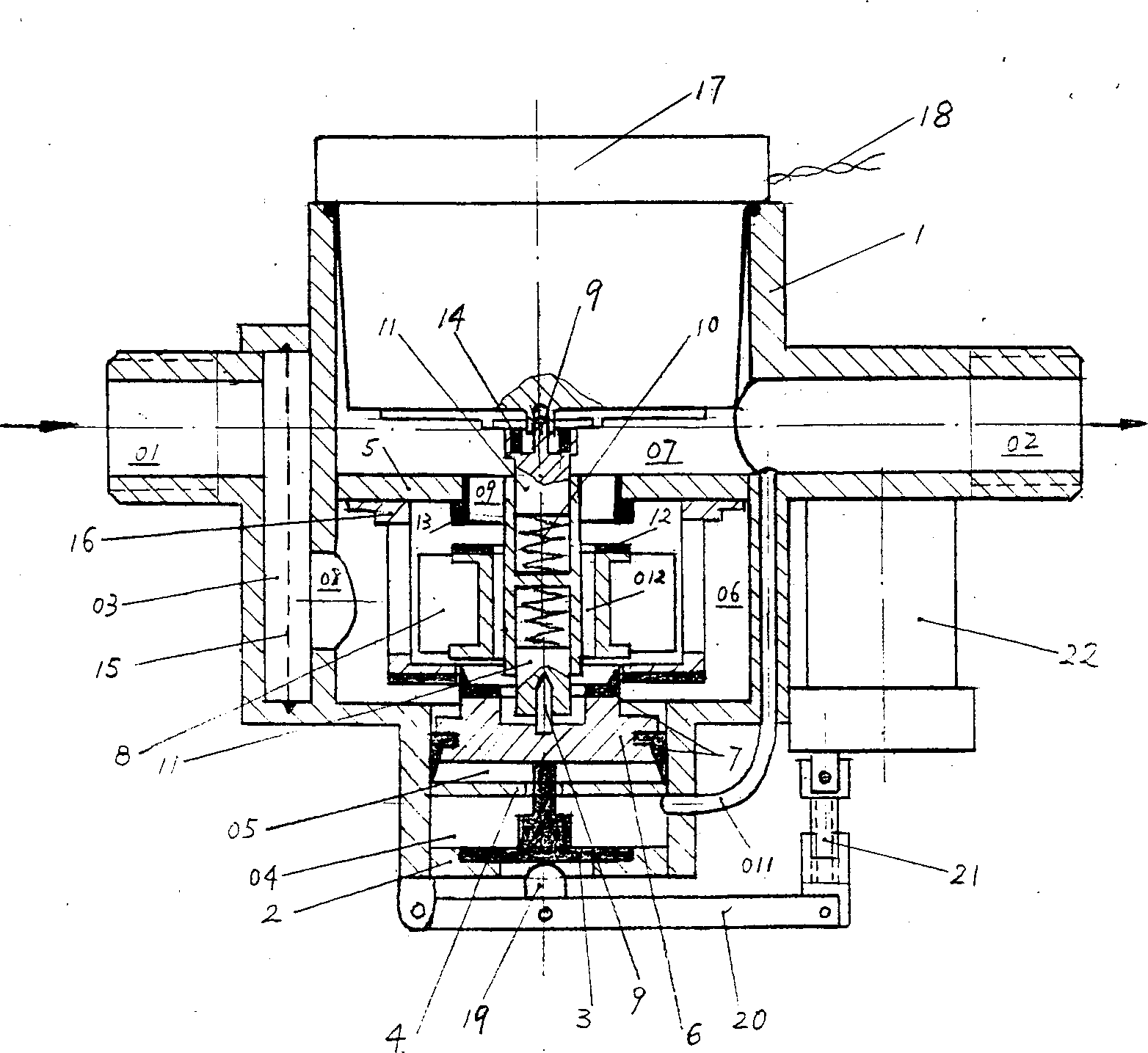

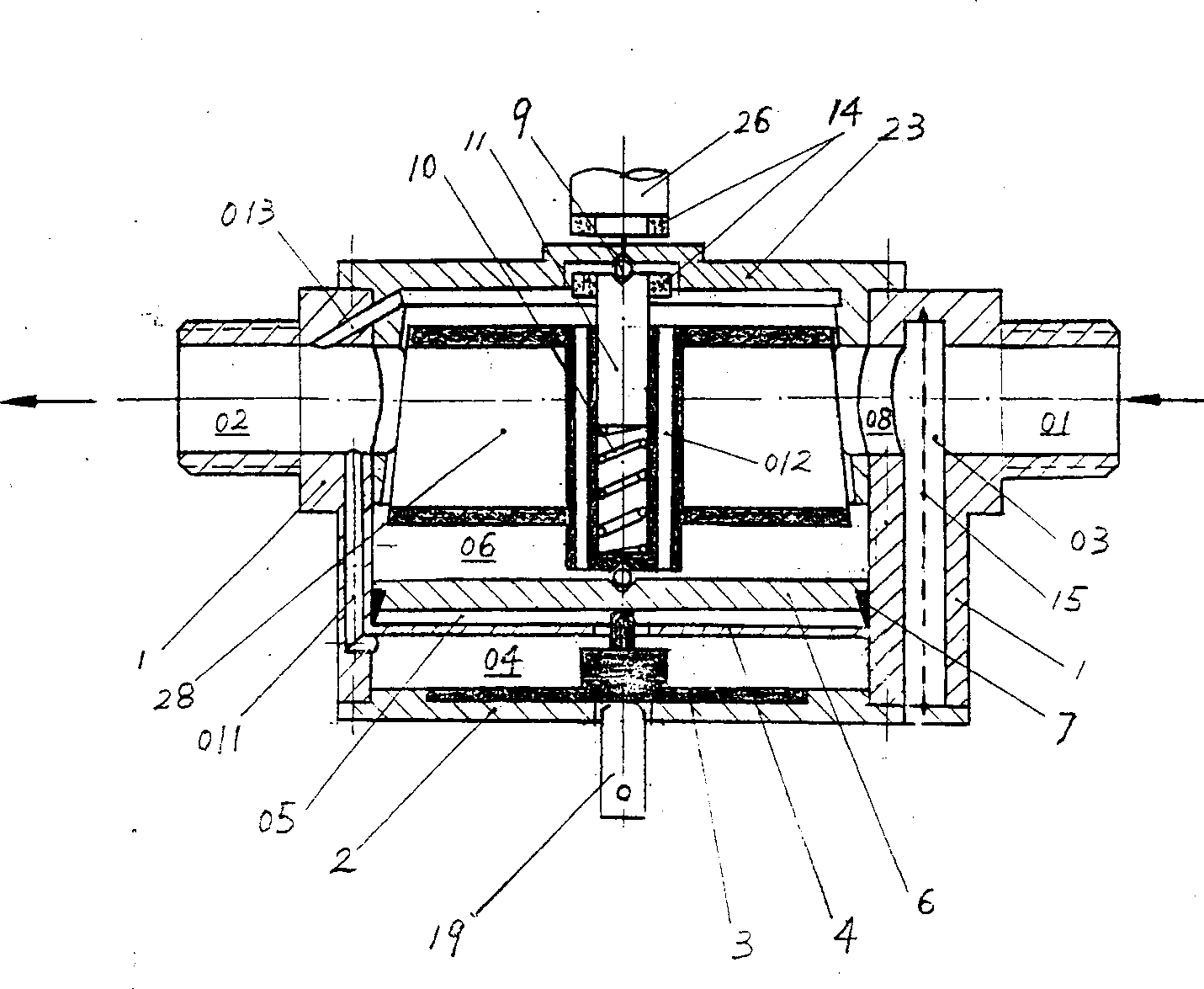

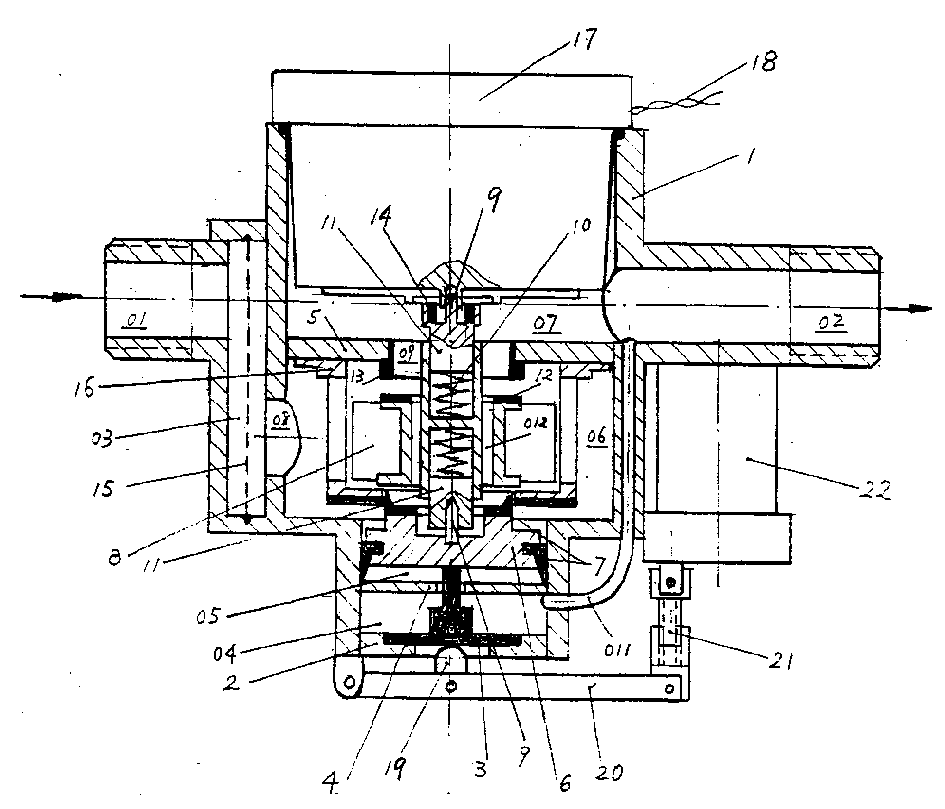

[0006] Provide the preferred scheme of implementing the present invention below, and illustrate in conjunction with accompanying drawing.

[0007] like figure 1 The first design scheme of the pilot-operated differential valve with metering function shown is composed of a housing (1), an end cover (2), a diaphragm (3), a lower partition (4), an upper partition (5) , piston (6), rubber ring (7), impeller (8), bearing (9), spring (10), short shaft (11), valve plug (12), valve seat (13), permanent magnet ring (14 ), filter screen (15), shroud (16), water meter head (17), measurement pulse lead wire (18), pressure head (19), lever (20), screw pair (21) and motor (22) constitute. Wherein the housing (1) is divided into two chambers. Fluid first enters the filter chamber (03) through the inlet (01), and there is a filter screen (15) inside to prevent slightly larger particles from entering the working chamber behind and hindering the action of the movable components. The filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com