Efficient double-inlet channel rotational flow atomization desulfurization nozzle

A technology of inlet channels and desulfurization nozzles, which is applied in the field of high-efficiency double inlet channel swirling atomization desulfurization nozzles, can solve the problems of reducing the effective reaction probability of flue gas and slurry, increasing desulfurization energy consumption, and large spray particle size, etc., to achieve improved Atomization effect and desulfurization efficiency, good spatial distribution uniformity, and improved flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

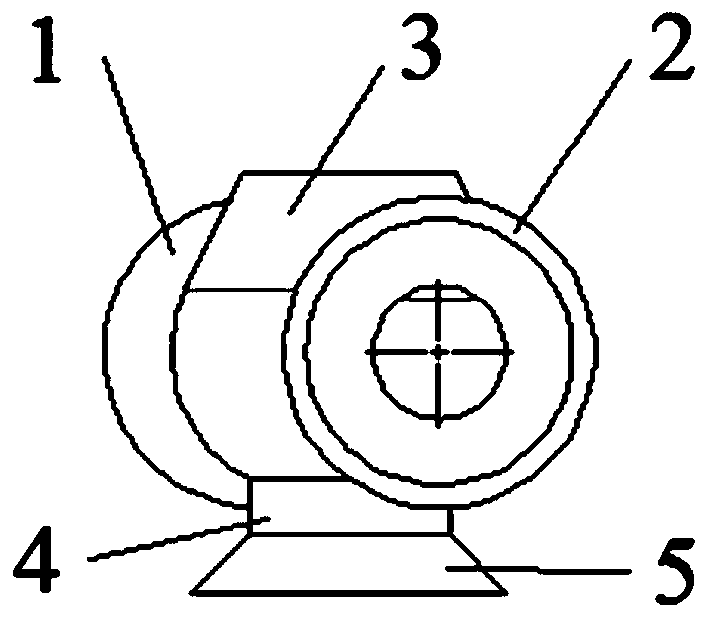

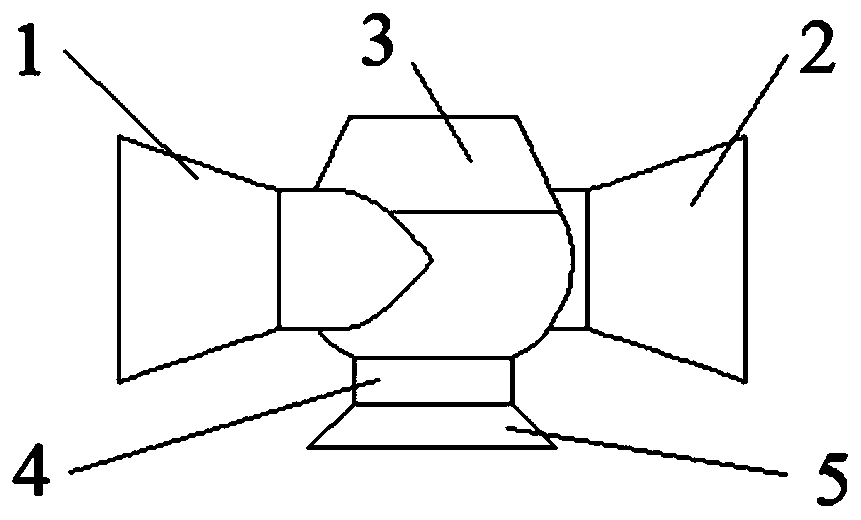

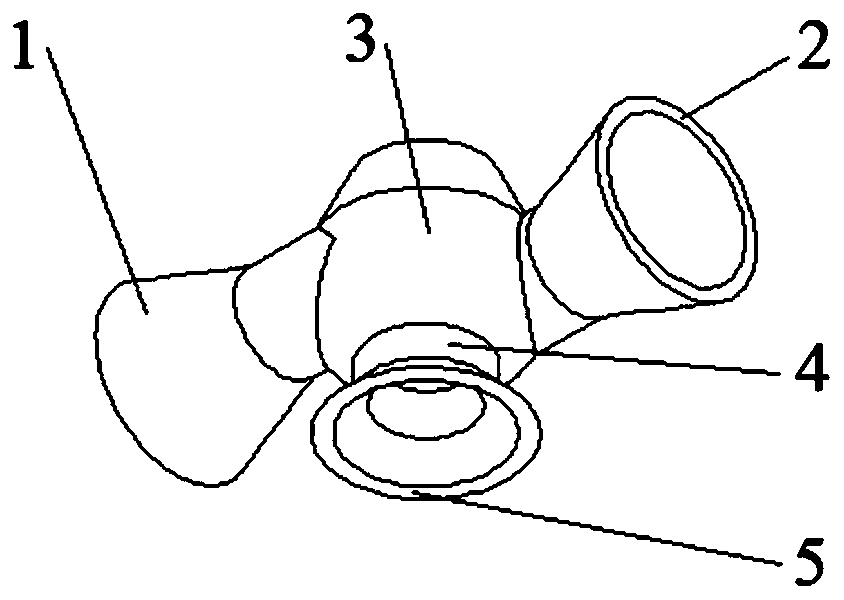

[0020] refer to figure 1 , figure 2 and image 3 , the high-efficiency double inlet channel swirl atomization desulfurization nozzle of the present invention includes a swirl chamber 3, a first inlet channel 1, a second inlet channel 2, an outlet straight pipe section 4 and an outlet flaring section 5, wherein the first The inlet channel 1 is connected with the left inlet of the cyclone chamber 3, the second inlet channel 2 is connected with the right inlet of the cyclone chamber 3, and the upper end of the outlet straight pipe section 4 is connected with the bottom outlet of the cyclone chamber 3 The lower end of the outlet straight pipe section 4 communicates with the outlet flaring section 5; the inner wall of the front side of the first inlet channel 1 is tangent to the inner wall of the front side of the swirl chamber 3, and the inner wall of the second inlet c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com