Valve head for pulse solenoid valve

A pulse solenoid valve, valve head technology, applied in the valve operation/release device, valve details, valve device and other directions, can solve the problem of increasing the gap between the moving iron and the static iron core, reducing the stability of the valve head, and unable to close the water flow and other problems, to achieve the effect of improving assembly accuracy, low power consumption, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

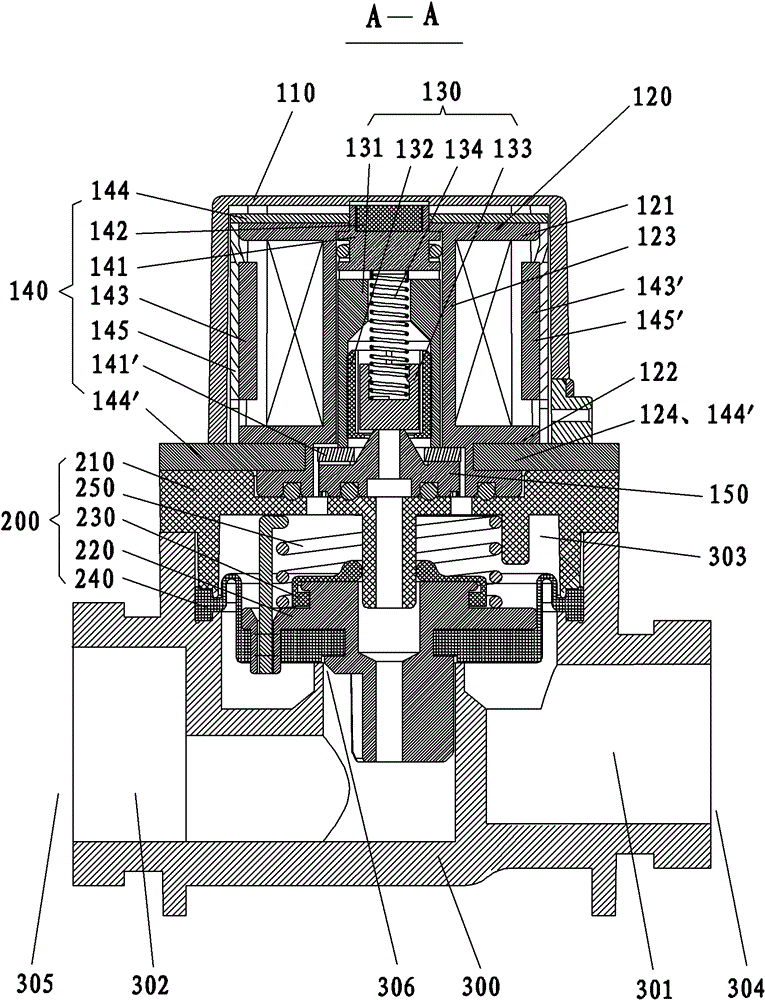

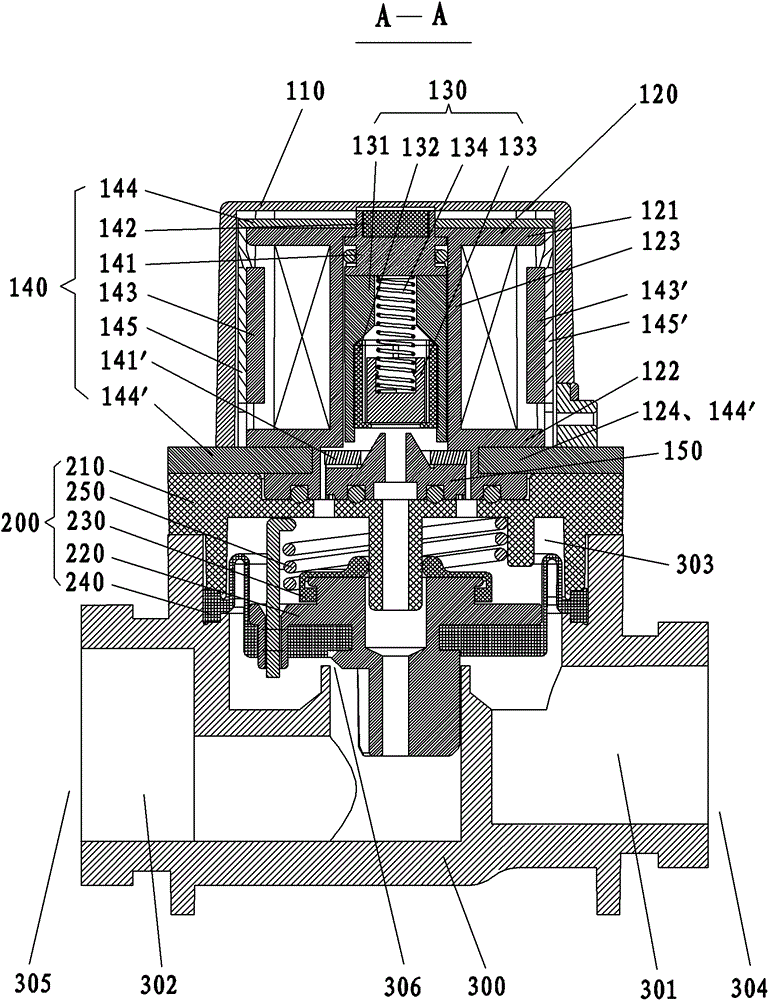

[0044] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

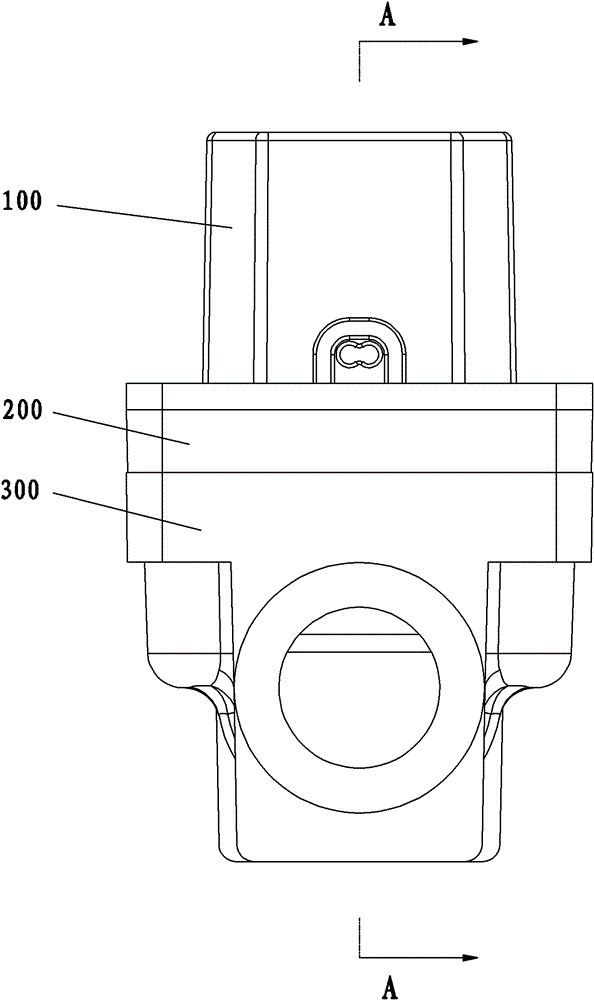

[0045] Such as Figure 1-11 As shown, the valve head 100 of the pulse solenoid valve of the present invention mainly includes a valve cover 110 , a coil bobbin 120 , a moving iron core assembly 130 , a static iron core assembly 140 and a pressure relief nozzle 150 . The valve head 100 is used as the main part of the pulse solenoid valve, and cooperates with the diaphragm assembly 200 and the valve body 300 .

[0046] The valve cover 110 is cap-shaped, with the opening facing downwards. The valve cover 110 is fastened on the lower permeable magnet piece 144' to form a closed space for accommodating the coil bobbin 120 and the moving iron core assembly 130, etc.

[0047] The coil frame 120 is made of a non-conductive and magnetically permeable material, and includes an upper retaining ring 121 , a bobbin 123 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com