Gas turbine low-pollution combustion chamber single-vortex head structure

A gas turbine, low-pollution technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of head structure spontaneous combustion, oscillating combustion, head outlet tempering, etc., to reduce the risk of spontaneous combustion and improve mixing uniformity Speed, the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

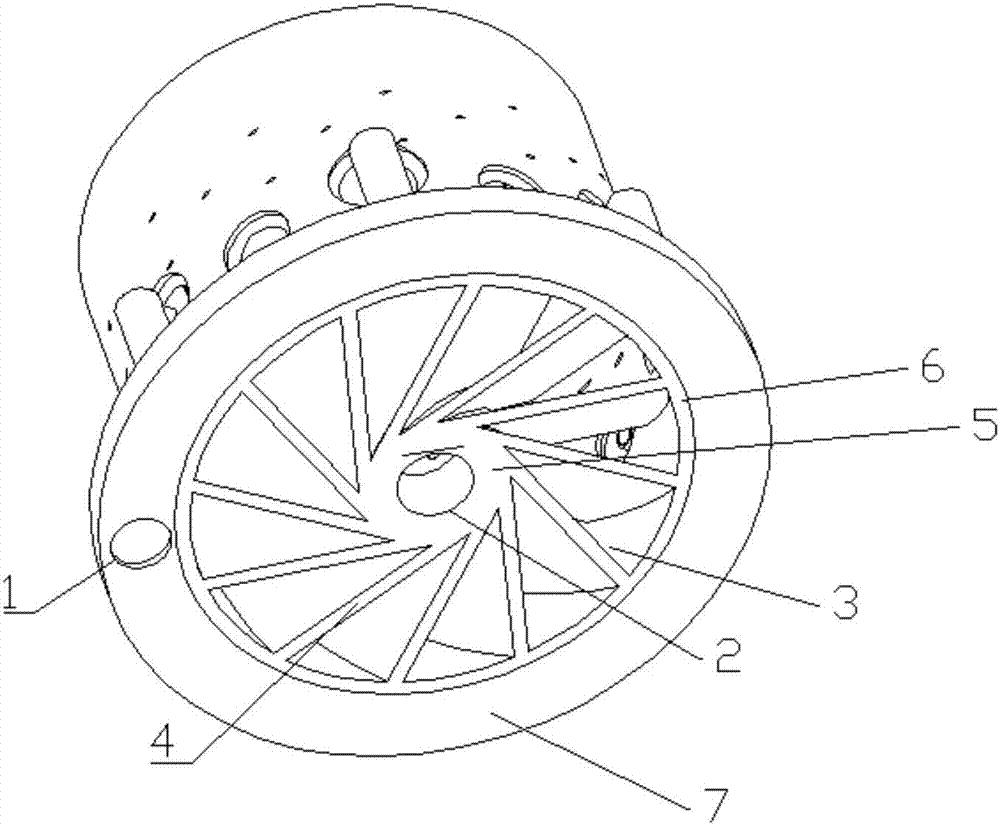

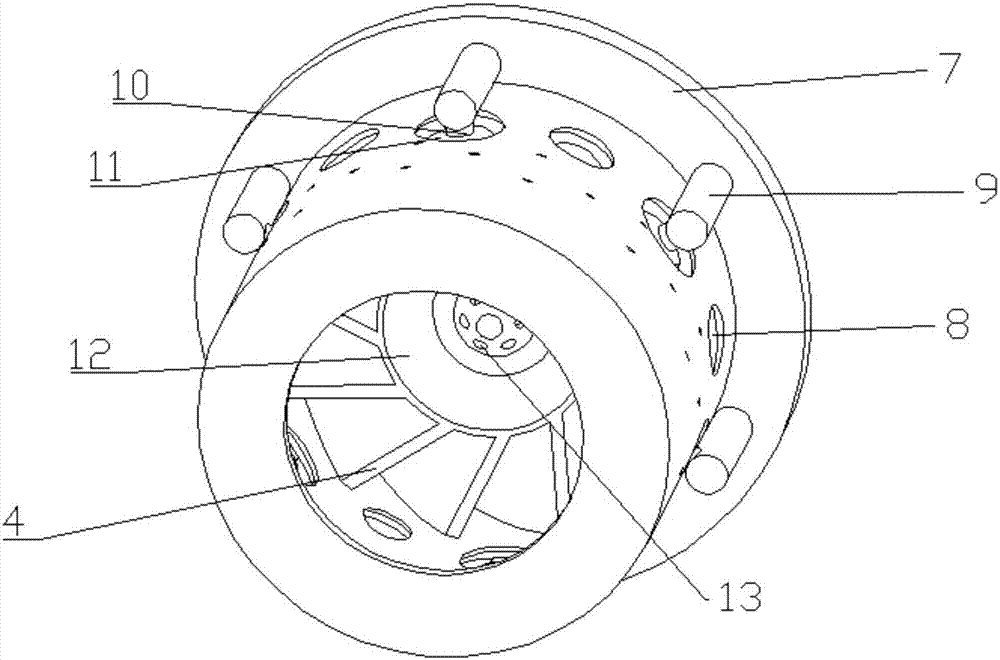

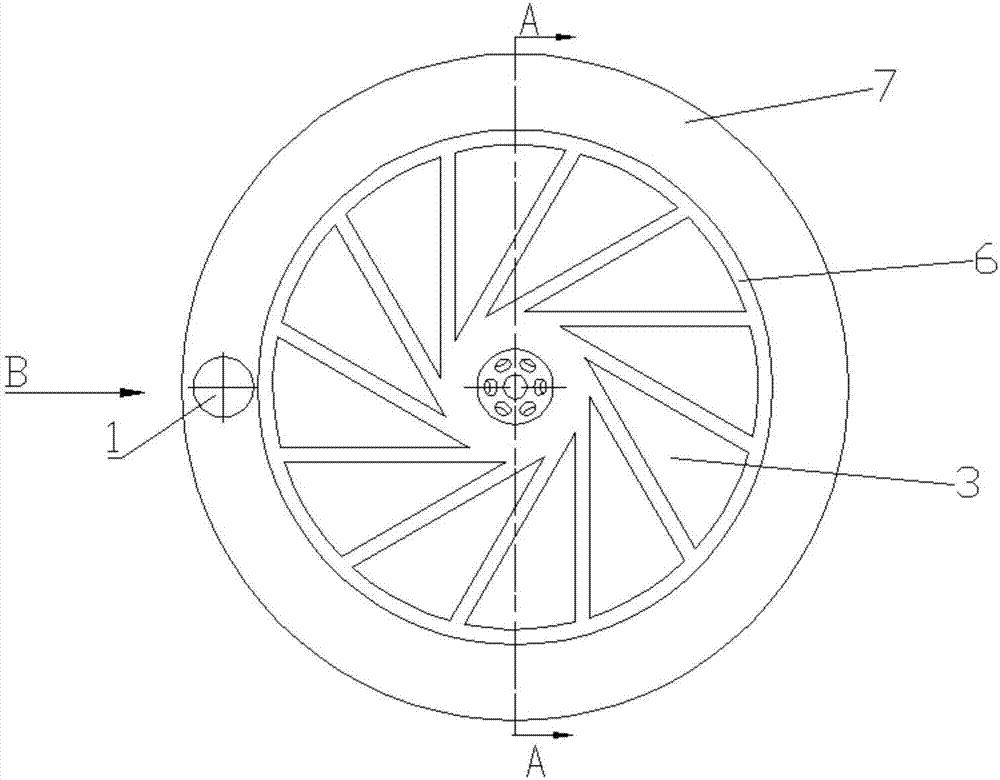

[0028] The solution adopted by the present invention to solve the technical problem is: a lean-burn premixed single-swirl head solution for a low-pollution combustion chamber of a ground gas turbine fueled by natural gas, including a central swirling air supply part, a central natural gas supply gas part, non-swirling air supply part on the outer wall, natural gas supply part on the outer wall, natural gas-air mixing chamber, head outlet convergence section, head mixed gas outlet. The central swirling air part includes axial flow swirler, swirler blade, central swirling air inlet, and swirler outlet baffle; the central natural gas supply part includes central natural gas inlet, central natural gas injection boss, central natural gas Injection hole: The air passes through the cyclone to generate a swirl flow, then accelerates through the converging section of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com