Narrow-band concurrent steam condenser tube bundle with dual-trapezoid air cooling region

A technology of air-cooling area and condenser, which is applied in the direction of steam/steam condenser, lighting and heating equipment, etc. It can solve the problem of increasing the steam resistance of steam flowing through the main condensation area, taking away uncondensed gas, and raising the condenser Pressure and other problems, to achieve the effect of obvious cooling effect, small degree of supercooling, and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

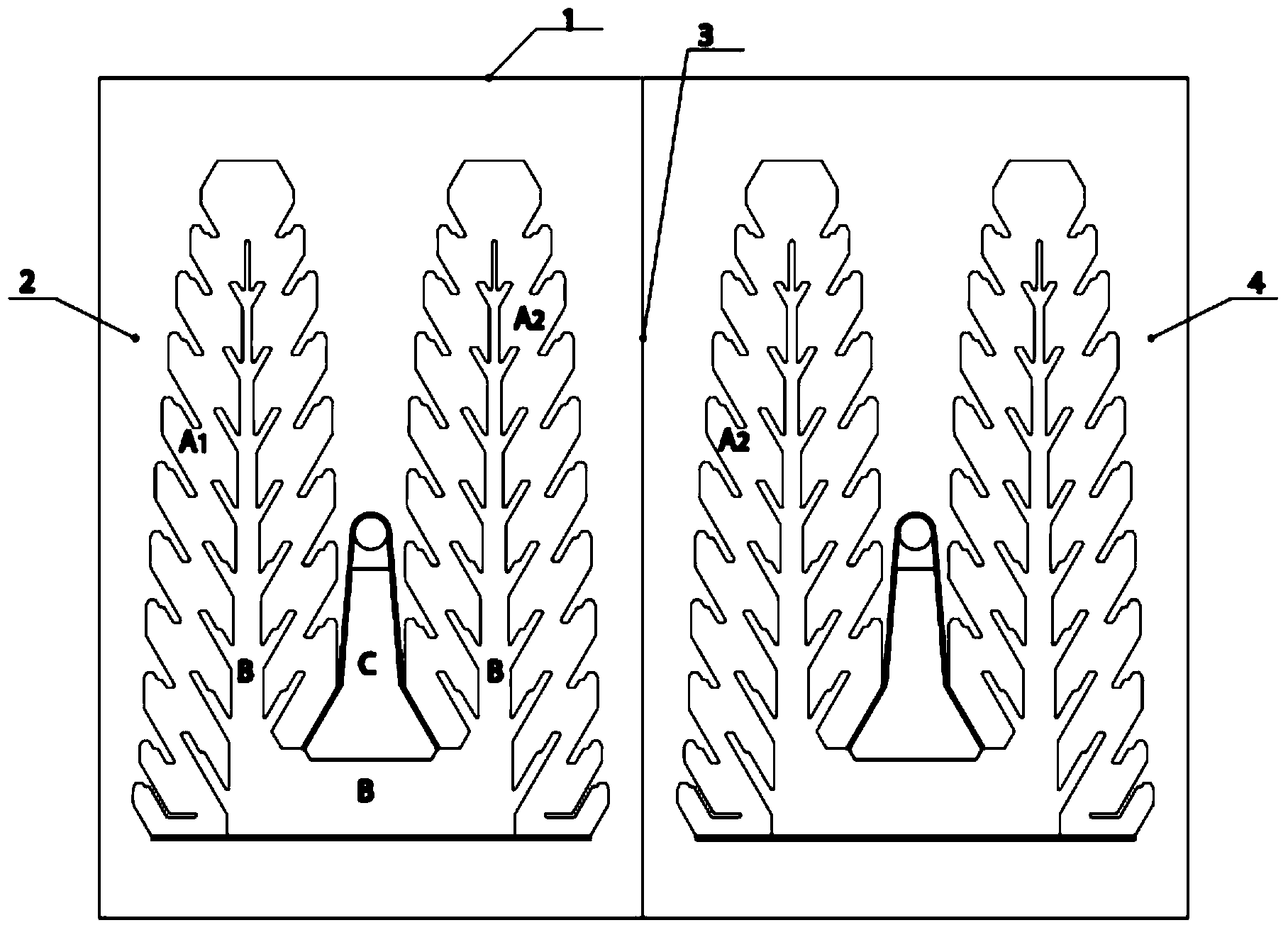

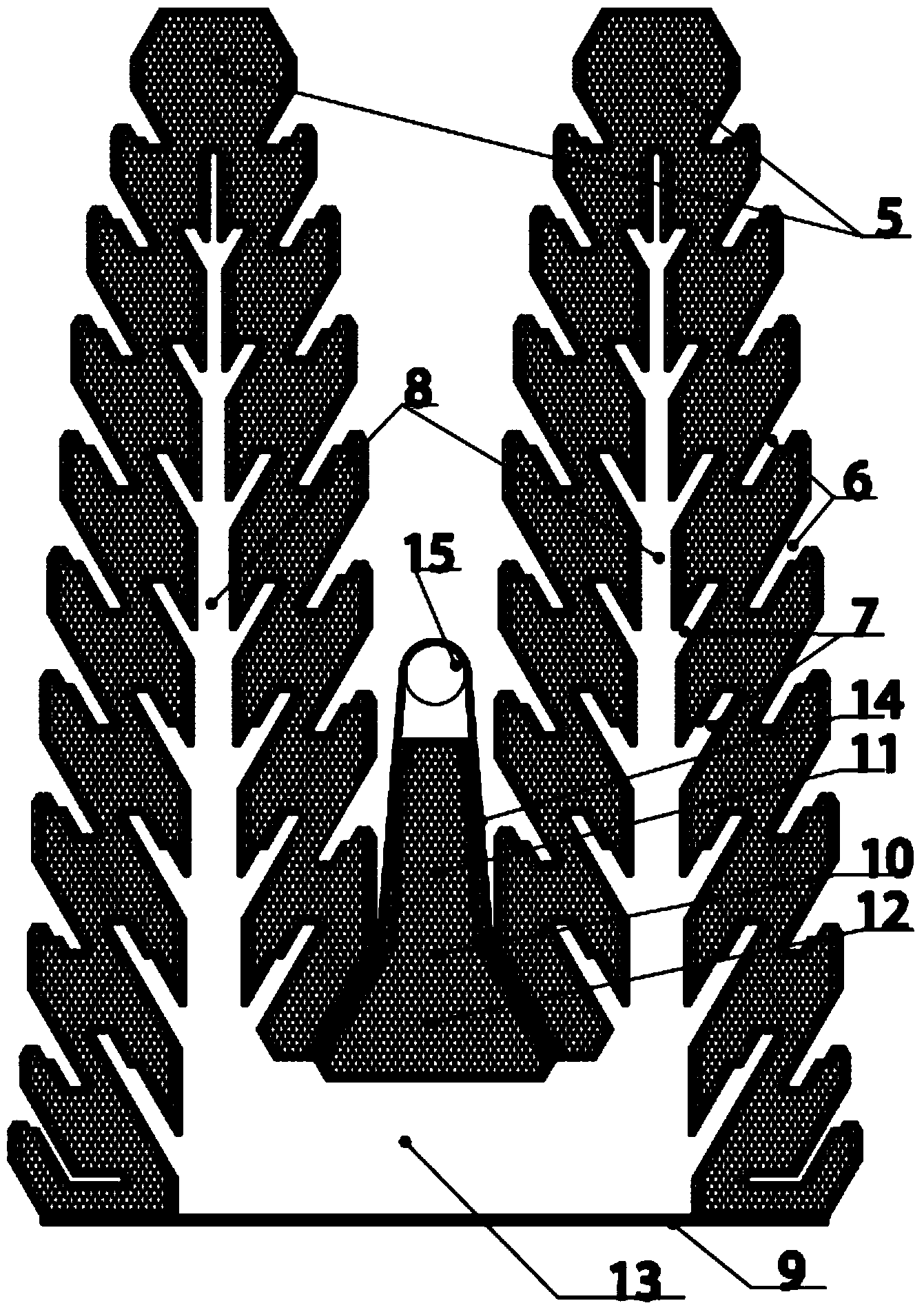

[0033] This embodiment is a cooling water single tube structure, such as figure 1 As shown, the tube bundle part of the condenser is formed by two identical tube bundles of the present invention arranged symmetrically. The periphery of the left module tube bundle forms the left main steam channel 2 with the left side of the condenser shell 1, the middle main steam channel 3 is formed between the two tube bundle modules, and the periphery of the right module tube bundle forms with the right side of the condenser shell Right main steam channel 4. The setting of the width of the main steam channel should be based on the fact that the flow velocity of the steam in this place is 70-90m / s. If the width of the main steam channel is too large or too small, the steam flow field will be unreasonable, resulting in a decrease in heat transfer or a decrease in steam resistance. Increase.

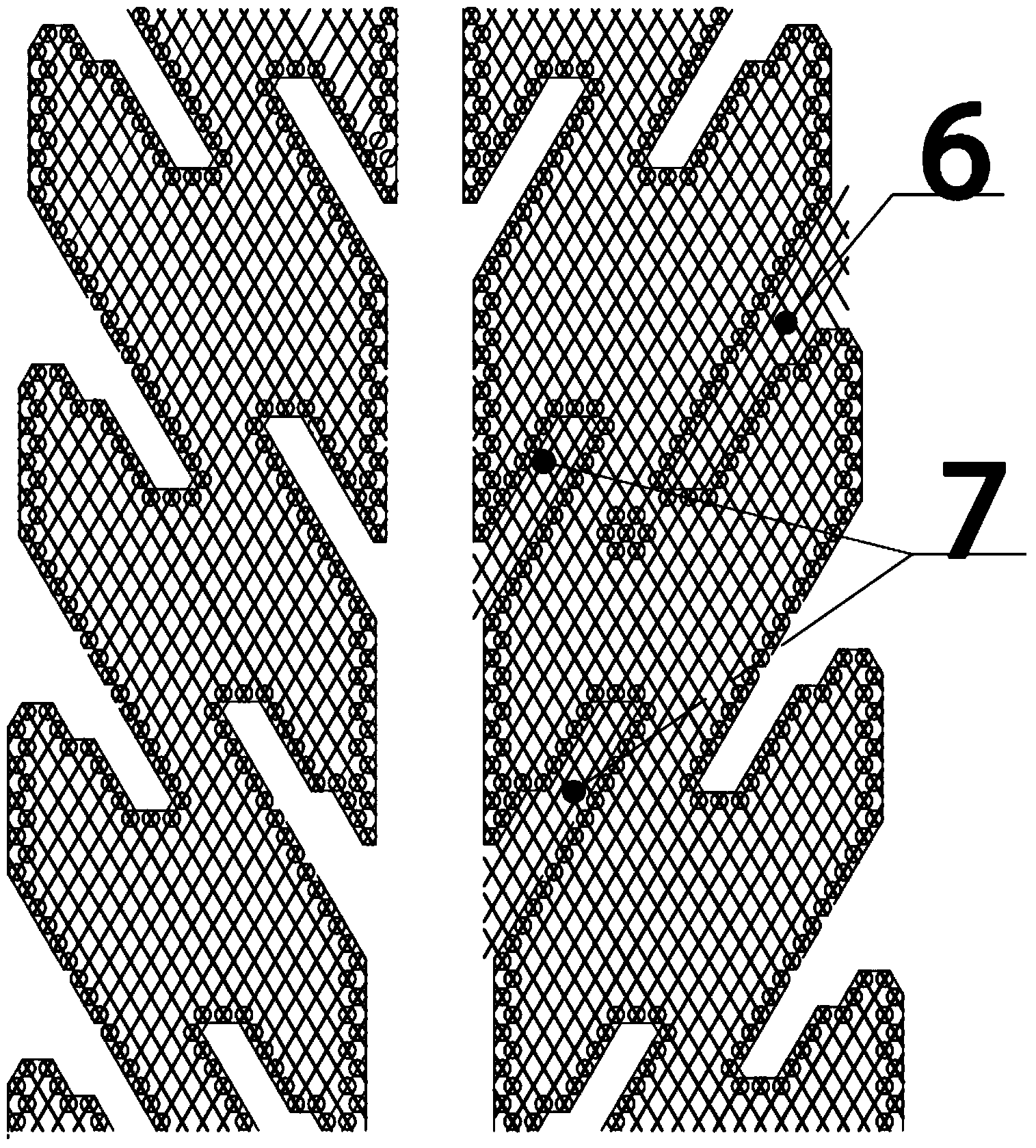

[0034] exist figure 1 In the above, taking the tube bundle on the left as an example, the tube bun...

Embodiment 2

[0043] The similarities between this embodiment and the first embodiment will not be described, and only the differences will be described.

[0044] In this embodiment, the tube bundle is a cooling water double-tube structure with upper and lower halves, such as Figure 6 As shown, the middle part of the tube bundle is provided with a plurality of zigzag split-range steam baffles 16 .

Embodiment 3

[0046] The similarities between this embodiment and the first embodiment will not be described, and only the differences will be described.

[0047] Such as Figure 7 As shown, the tube bundle part of the condenser in this embodiment is composed of four tube bundles according to the present invention, and the tube bundles are all cooling water single-pass structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com