Improved large-size generator set condenser

A technology for generating sets and condensers, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problem of reducing the operating economy and output of generating sets, affecting the safety and reliability of generating sets, and supercooling of condensed water In order to avoid problems such as high temperature, it can achieve the effect of low transformation cost, fast installation and uniform heat load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

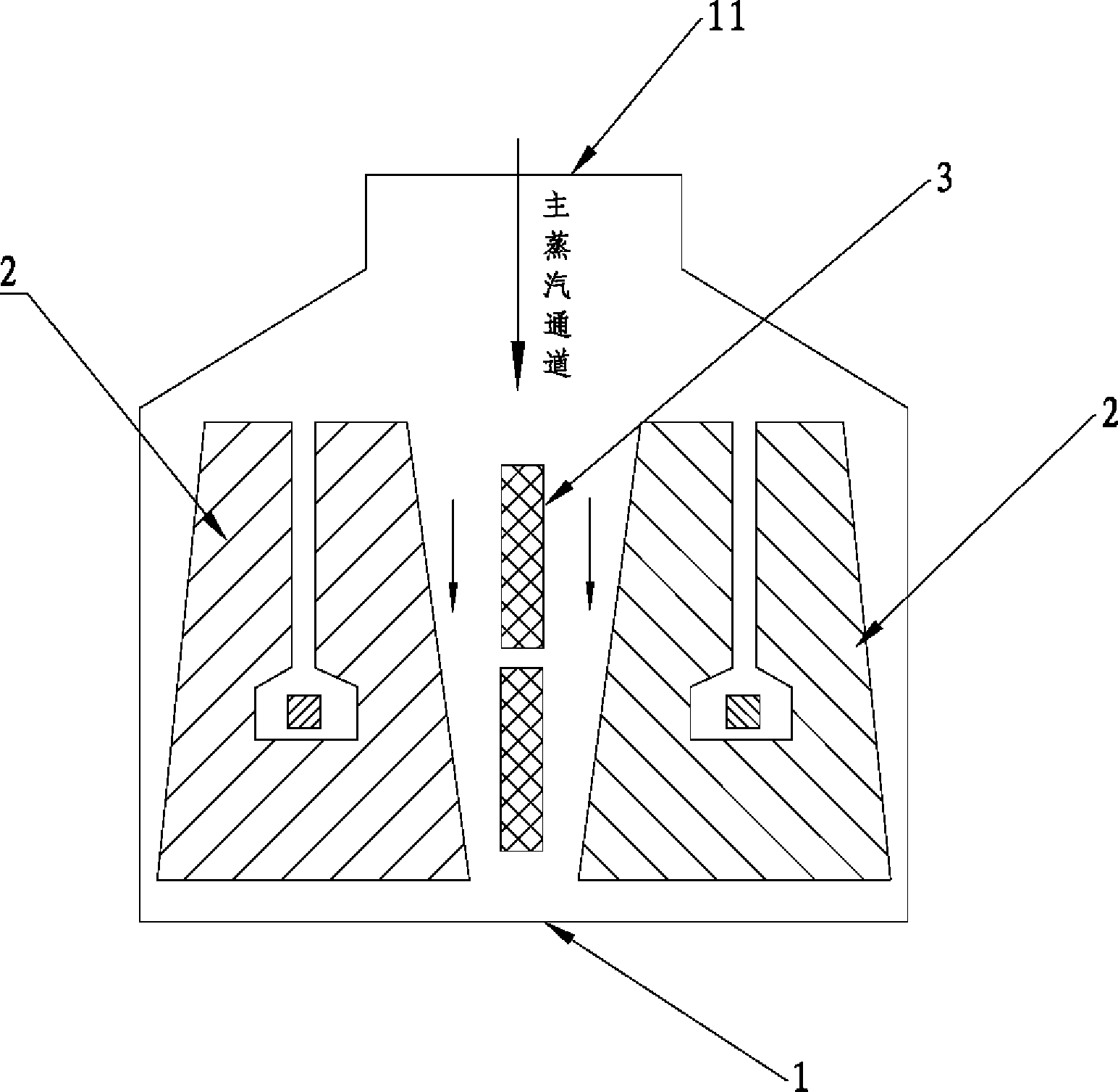

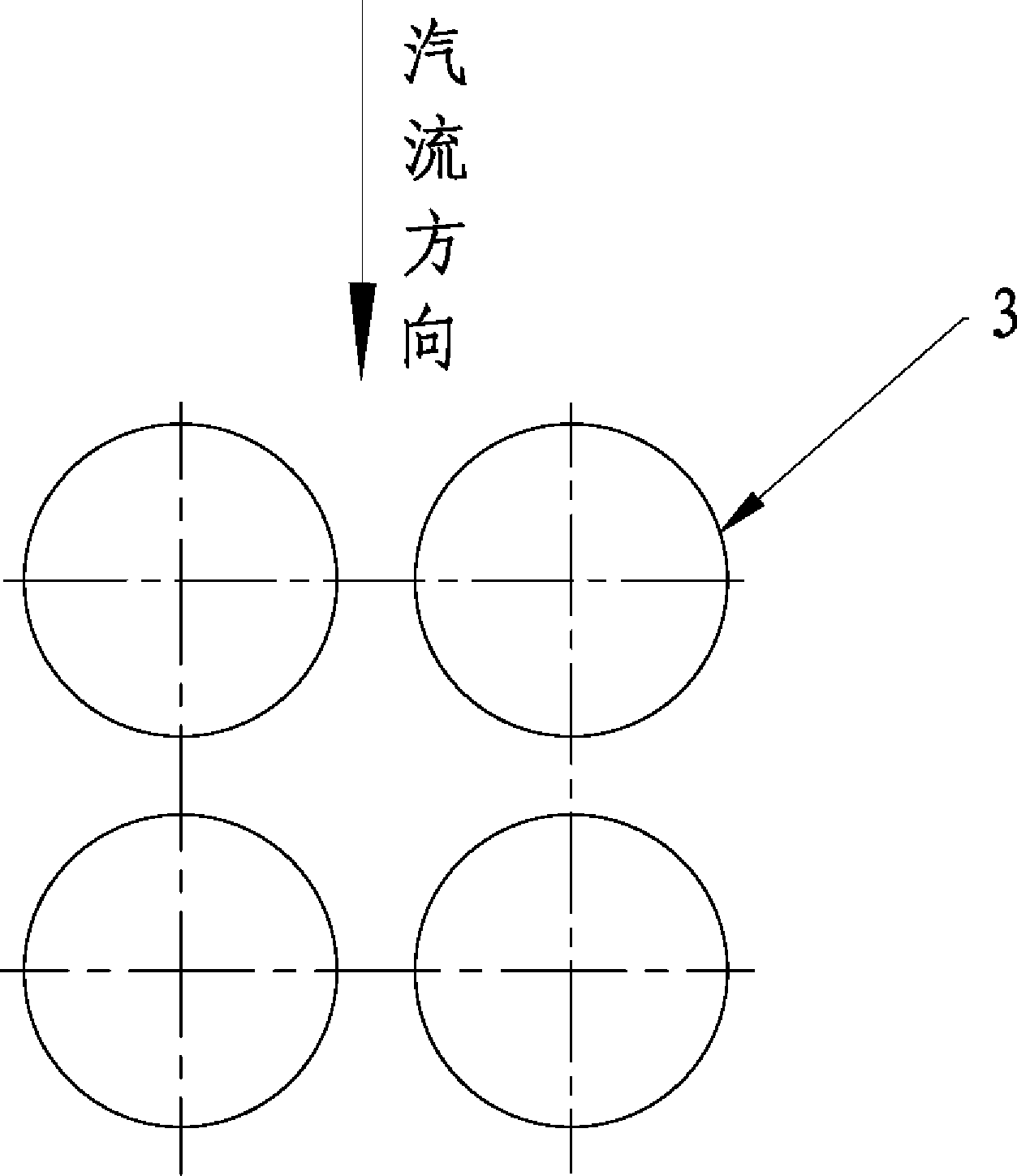

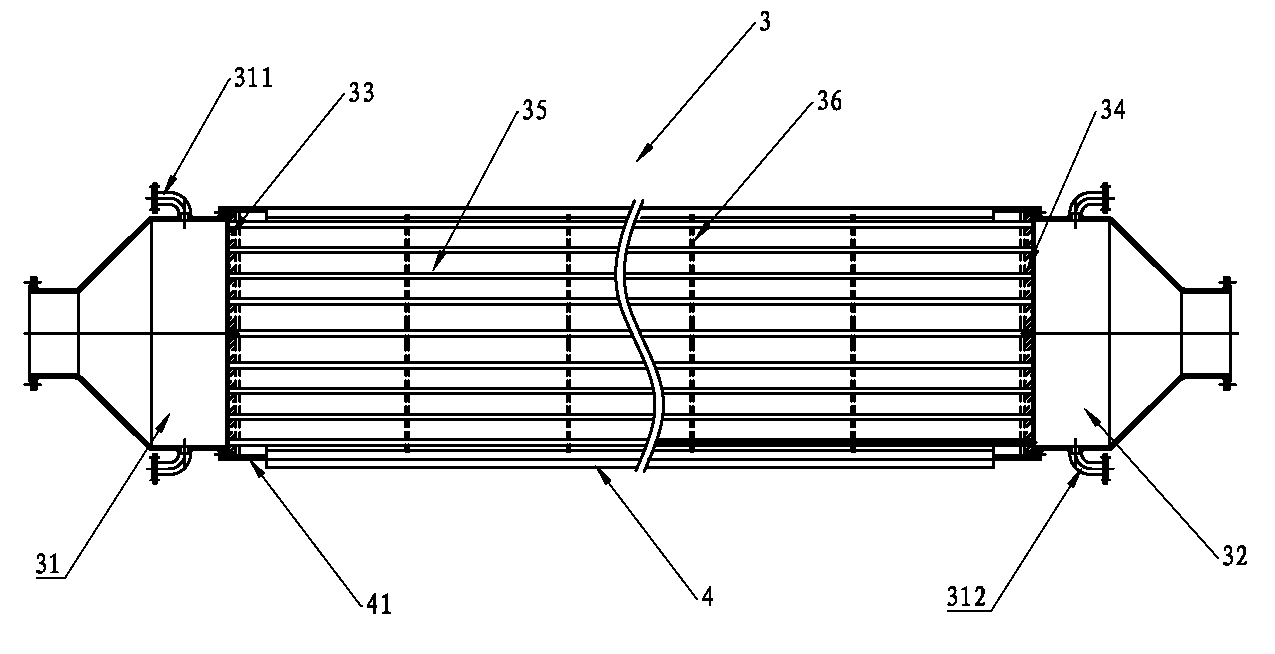

[0042] An improved large -scale generator crew, such as figure 1 As well as figure 2 and image 3 It shows that the two groups of main condensation pipe bundles 2 in the shell 1, and the end of the shell 1 are set with steam entrance 11, and the two groups of main condensate tubes 2 are set in the direction of the steam circulation in the shell 1 respectively.On both sides, the main steam channel is formed, and there are multiple sets of heat exchanges 3 in the middle of the main steam channel. Multi -group heat exchanges bundle 3 is arranged in matrix, and the number and vertical layout of each horizontal arrangement of heat exchanges 3The number of heat exchanges 3 is equal;

[0043] The gap between the adjacent heat exchanges bundle 3 in multiple groups of heat exchanges 3 is equal; and the steam passage is set up between the thermal change tube 3 and the main coagulation tube bundle 2 on the outside.

[0044] In this embodiment, under the premise of not affecting the safe opera...

Embodiment 2

[0055] Taking the 600MW large -scale generator crew as an example, the structure after the renovation of the condenser is the same as the embodiment 1. The analysis of its transformation cost and energy saving benefits is as follows:

[0056] 1. The condenser before the transformation

[0057] 1. Main technical data

[0058] 1.1 Gas with a condenser model N-36000-4

[0059] 1.2 Type -type double -back pressure, double shell, single process, surface, horizontal layout

[0060] 1.3 cooling area

[0061] Total cooling area 36000M 2

[0062] Cooling area of condensa A cooling area 18000M 2

[0063] Cooling area of condenser B 18000M 2

[0064] 1.4 Cooling medium seawater

[0065] 1.5 Design cooling water import temperature 21.9 ℃

[0066] 1.6 Design cooling water 20.85m3 / s

[0067] 1.7 Design flow rate in the cooling water pipe 2.24m / s

[0068] 1.8 Concubine water resistance ≤ 90kPa

[0069] 1.9 Design pressure (vacuum) of the condenser

[0070] Average back pressure 4.9kPa

[0071...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com