Flow guide structure and flow guide method for condenser

A technology of a condenser and a deflector is applied in the field of thermal power generation steam turbine condenser devices, which can solve the problems of one-sided analysis, ignoring the internal structure and flow field of the condenser shell, large steam resistance, etc., so as to reduce the steam resistance. 、Convenient heating upgrade and transformation, reducing the effect of operating back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

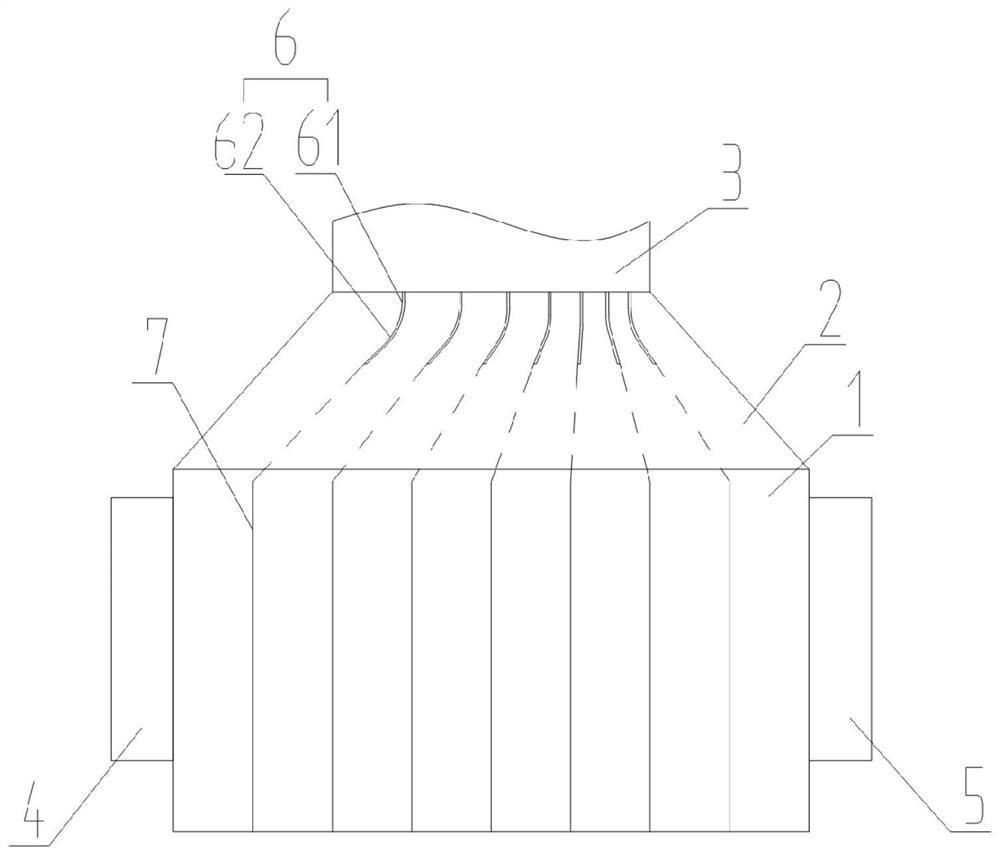

[0033] A diversion structure for condensers, such as figure 1 As shown, it includes a housing 1, and the upper part of the housing 1 is provided with a condenser throat 2, and the condenser throat 2 is connected to the exhaust port 3 of the low-pressure cylinder;

[0034] The housing 1 is provided with a cooling liquid inlet 4 and a cooling liquid outlet 5, and a heat exchange tube is arranged inside the housing 1, and the heat exchange tube communicates with the cooling liquid inlet 4 and the cooling liquid outlet 5 to form a cooling liquid circulation channel. fluid passage;

[0035] A number of deflectors 6 are arranged inside the condenser, and a number of baffles 7 are also arranged inside the shell 1. The steam enters the condenser throat 2 through the exhaust port 3 of the low-pressure cylinder, and passes through the deflector. The plate enters the space isolated by the partition to achieve heat exchange cooling.

[0036] In this embodiment, the condenser is a commo...

Embodiment 2

[0046] A kind of diversion method for condenser, adopts a kind of diversion structure for condenser of embodiment 1, comprises the following steps:

[0047] a. Use partitions to divide the inner cavity of the condenser shell into several equal cooling cavities. The cooling cavities are A1, A2, A3, A4...An in turn; inside the condenser along the cooling liquid inlet and The amount of steam condensed in each cooling cavity in the direction of the coolant outlet is Q1, Q2, Q3, Q4...Qn;

[0048] b. A number of deflectors are set inside the condenser, through which the interior of the condenser is divided into several guide channels along the direction of the coolant inlet and coolant outlet, and the guide channels are B1, B2, B3, B4... Bn;

[0049] c. The deflector is divided into a vertical part and an arc part, and the vertical part and the arc part are integrally formed. At the same time, the arc plate is arc-shaped along the vertical direction for diversion of steam.

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com