An Improved Condenser for Large Generating Sets

A technology for generating sets and condensers, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problem of reducing the operating economy and output of generating sets, affecting the safety and reliability of generating sets, and supercooling of condensed water In order to avoid problems such as high temperature, it can achieve the effect of low transformation cost, fast installation and uniform heat load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

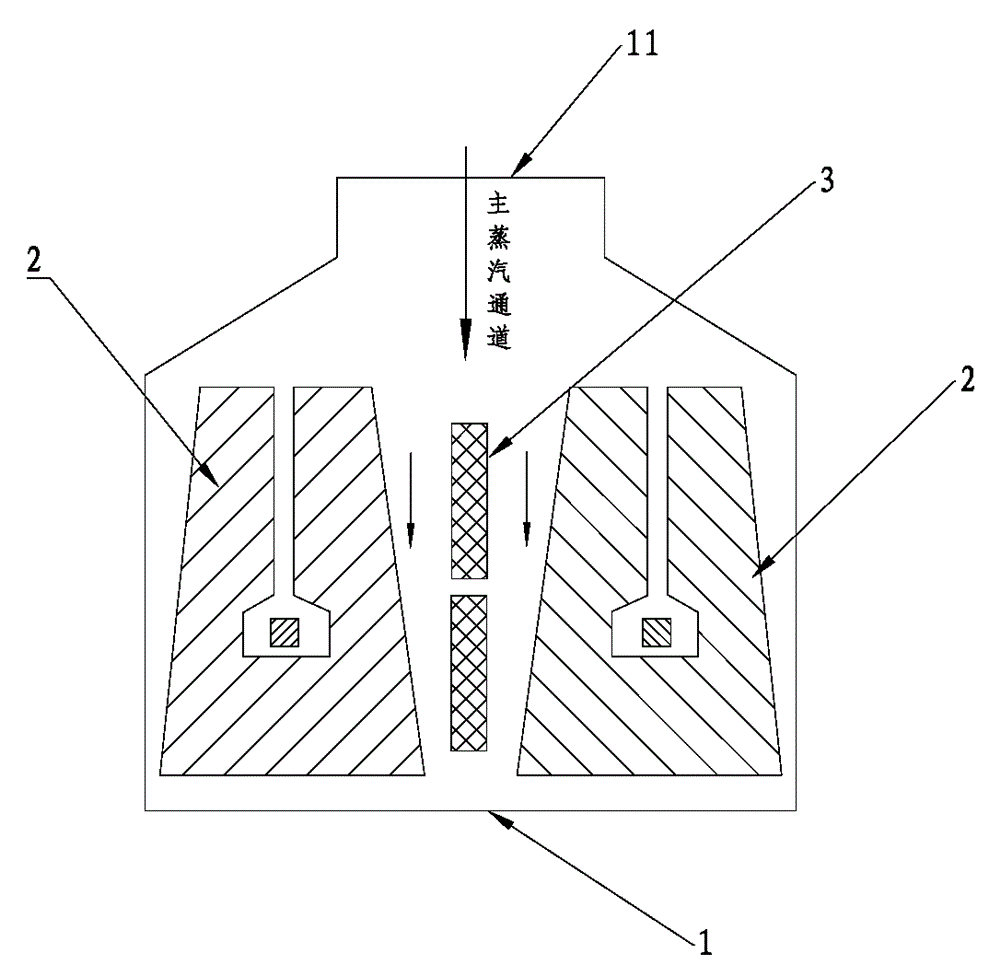

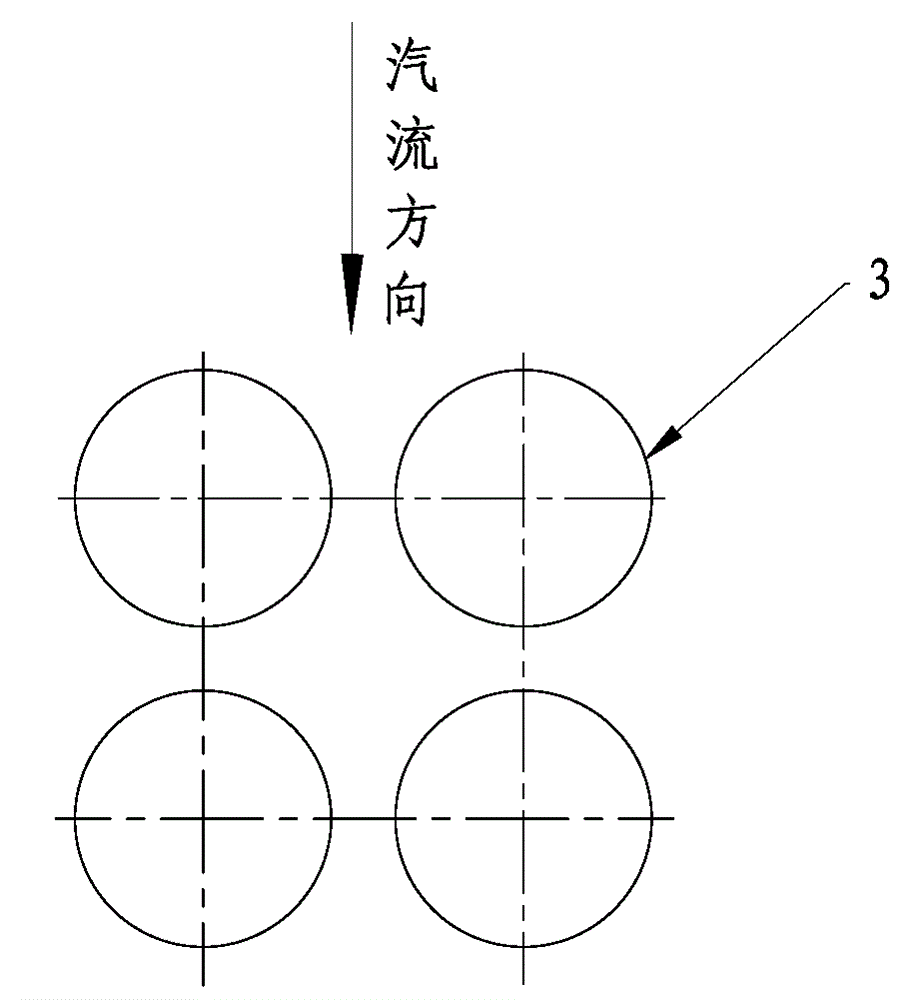

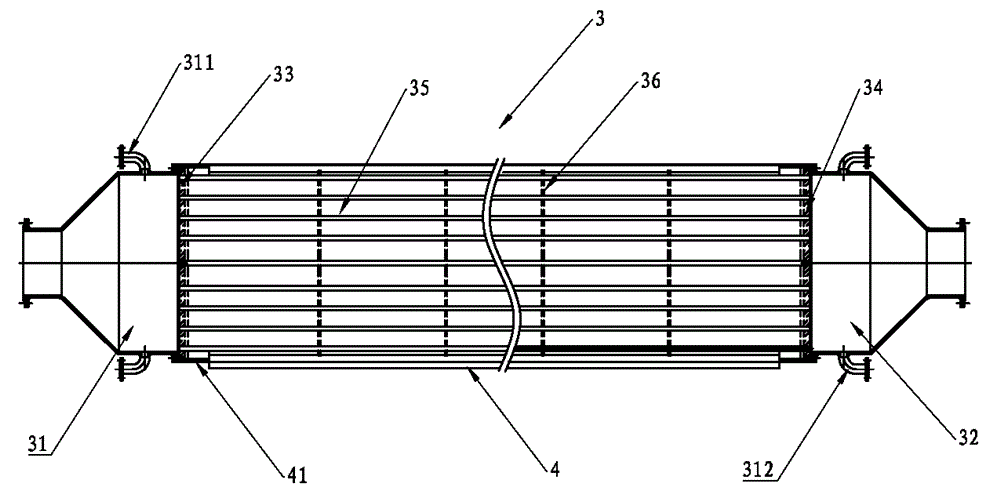

[0042] An improved large generator set condenser, such as figure 1 , figure 2 with image 3 As shown, it includes a casing 1 and two sets of main condensing tube bundles 2 arranged inside the casing 1, one end of the casing 1 is provided with a steam inlet 11, and two sets of main condensing tube bundles 2 are respectively arranged inside the casing 1 along the direction of steam flow. The two sides of the main steam channel are formed in the middle, and the middle part of the main steam channel is provided with multiple sets of heat exchange tube bundles 3, and the multiple sets of heat exchange tube bundles 3 are arranged in a matrix, and the number of each horizontally arranged heat exchange tube bundle 3 is the same as the longitudinal arrangement The number of heat exchange tube bundles 3 is equal;

[0043] The gaps between adjacent heat exchange tube bundles 3 in multiple sets of heat exchange tube bundles 3 are equal; and a steam channel is provided between the heat...

Embodiment 2

[0055] Taking the condenser of a 600MW large-scale generating set as an example for transformation, the structure of the condenser after transformation is the same as that of Example 1. The transformation cost and energy-saving benefits are analyzed as follows:

[0056] 1. Condenser before transformation

[0057] 1. Main technical data

[0058] 1.1 Condenser model N-36000-4

[0059] 1.2 Type Double back pressure, double shell, single flow, surface type, horizontal arrangement

[0060] 1.3 Cooling area

[0061] Total cooling area 36000m 2

[0062] Condenser A cooling area 18000m 2

[0063] Condenser B cooling area 18000m 2

[0064] 1.4 Cooling medium Sea water

[0065] 1.5 Design cooling water inlet temperature 21.9℃

[0066] 1.6 Design cooling water volume 20.85m3 / s

[0067] 1.7 The design flow velocity in the cooling water pipe is 2.24m / s

[0068] 1.8 Condenser water resistance ≤90KPa

[0069] 1.9 Design pressure of condenser (vacuum)

[0070] Average back p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com