Radiation type rotary drying device for waste salt treatment

A technology of rotary drying and salt treatment, applied in non-progressive dryers, heating devices, drying solid materials, etc., can solve the problems of inability to achieve organic matter removal effect, affect treatment steps, low temperature, etc., and achieve constant temperature and uniform heating , to ensure the effect of flue gas flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

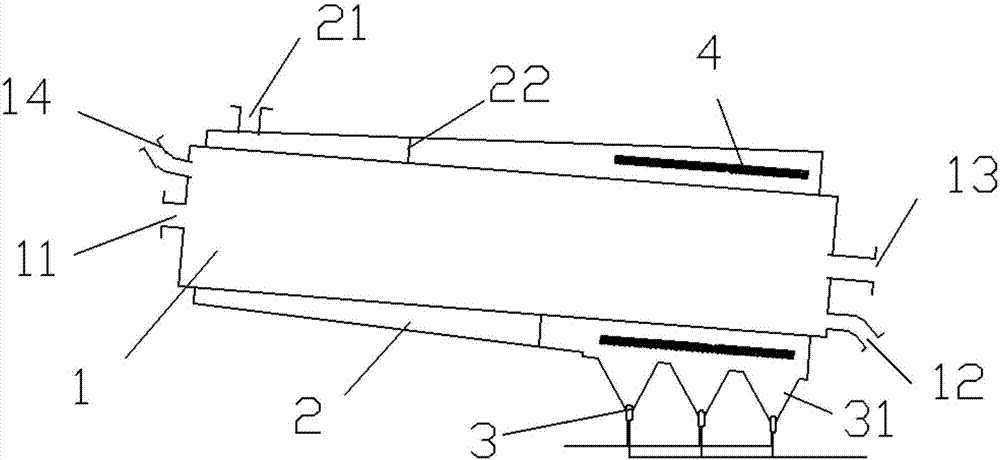

[0019] like figure 1 and 2 As shown, a radiant rotary drying device for waste salt treatment includes a rotary barrel 1, which is arranged obliquely, and a feed port is provided on the end face of the higher end of the rotary barrel 1 11 and the exhaust port 14, the discharge port 12 and the air inlet 13 are provided on the end face of the lower end of the rotary barrel 1, and the feature is that a heating jacket 2 is also provided on the outside of the rotary barrel 1 , the heating jacket 2 is fixed and does not rotate with the rotary barrel 1, the inclination direction and angle of the heating jacket 2 and the rotary barrel 1 are the same, and a burner 3 is arranged below the lower end of the heating jacket 2 , the flame nozzle 31 of the burner 3 is connected to the inner cavity of the heating jacket 2, and a heat radiation plate 4 is also arranged in the heating jacket 2, and the heat injection port of the burner 3 points directly to the heat radiation plate 4. Commonly u...

Embodiment 2

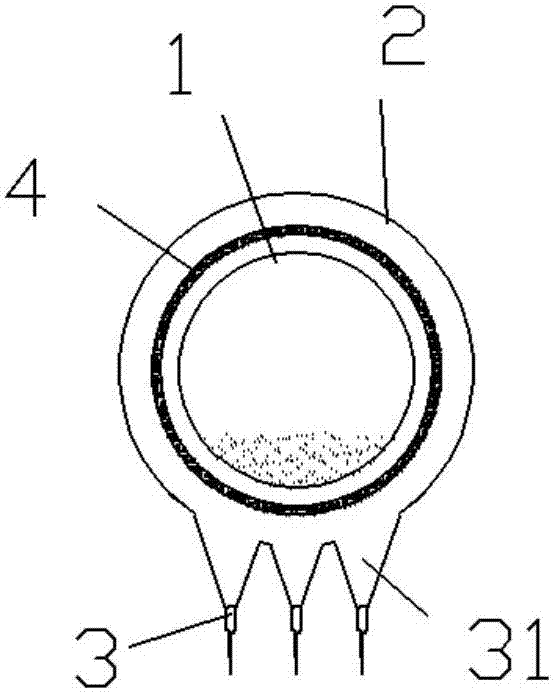

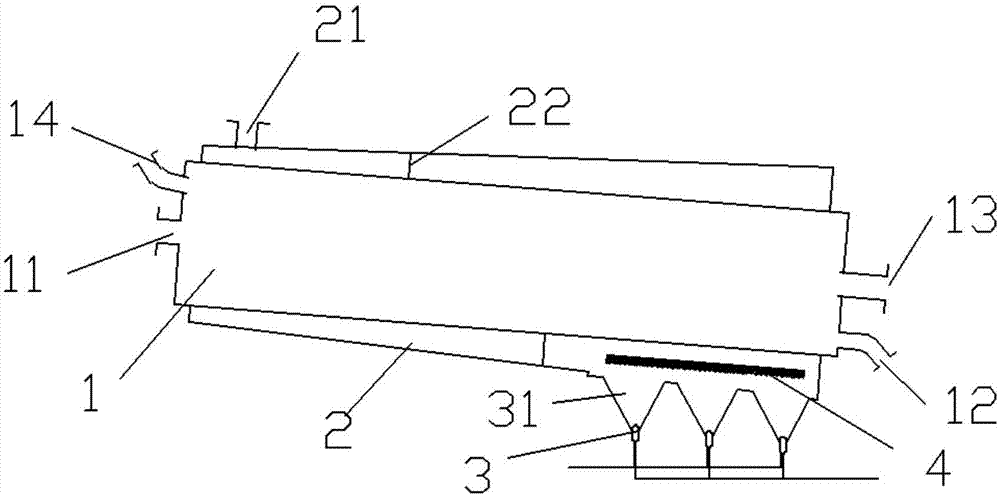

[0026] like image 3 and 4 As shown, the heat radiation plate 4 surrounds the heating jacket 2 in a cylindrical shape, the heat radiation plate 4 rotates synchronously with the rotating cylinder, and the heat radiation plate 4 and the rotating cylinder are arranged concentrically. The synchronously rotating heat radiation plate 4 can effectively disperse the heat of the flame and then conduct radiation heat transfer to the rotating cylinder. The temperature of the flame is generally significantly higher than the melting temperature of the waste salt, which will cause the temperature of the heat radiation plate 4 to be too high, making the temperature It is difficult to control. By rotating the heat radiation plate 4, the temperature of the flame is diluted and dispersed around the rotating cylinder to ensure uniform and stable heat supply. At the same time, the temperature of the heat radiation plate 4 can be conveniently adjusted to effectively control Waste salt treatment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com