Patents

Literature

62results about How to "Increase dissociation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

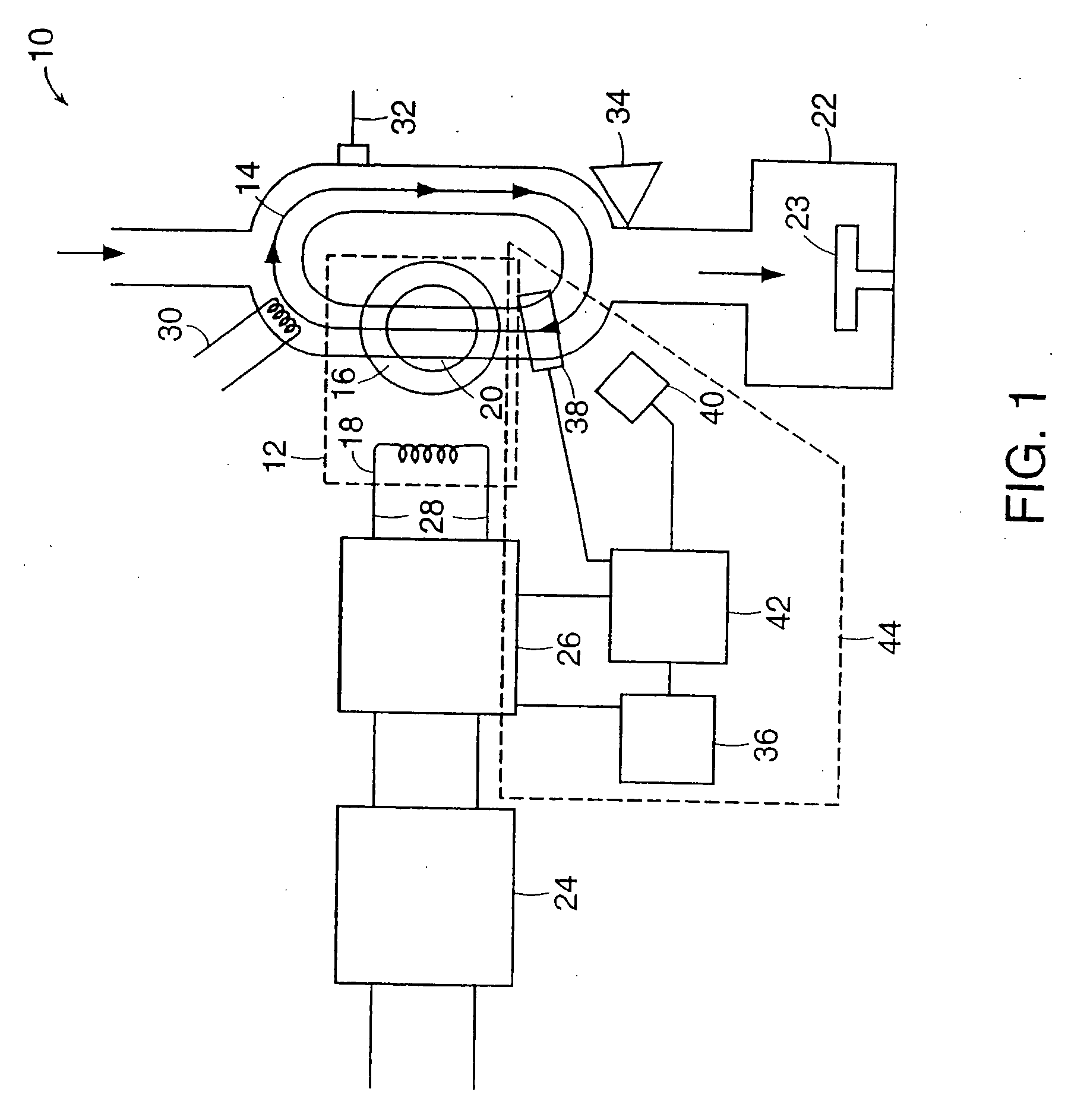

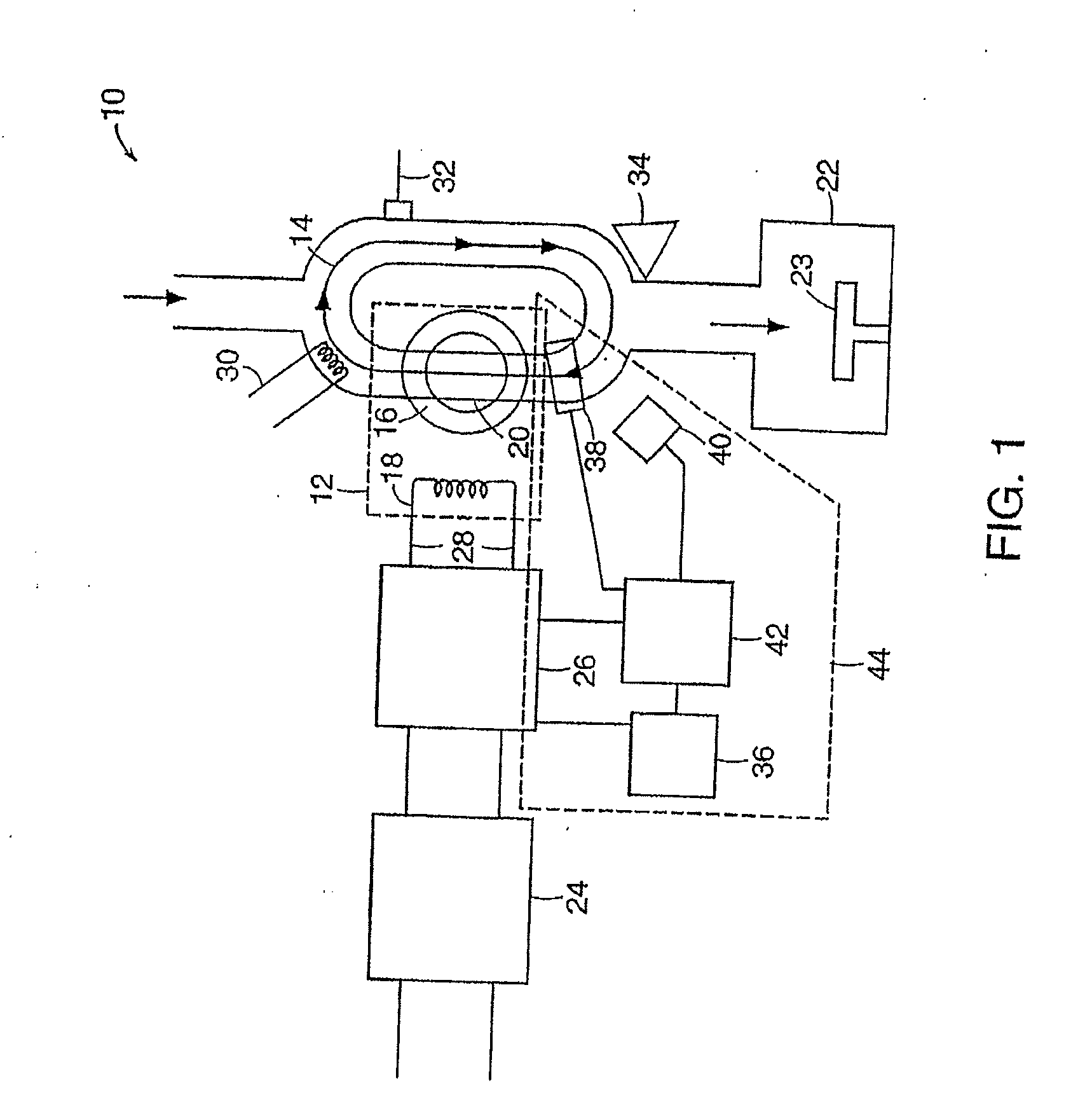

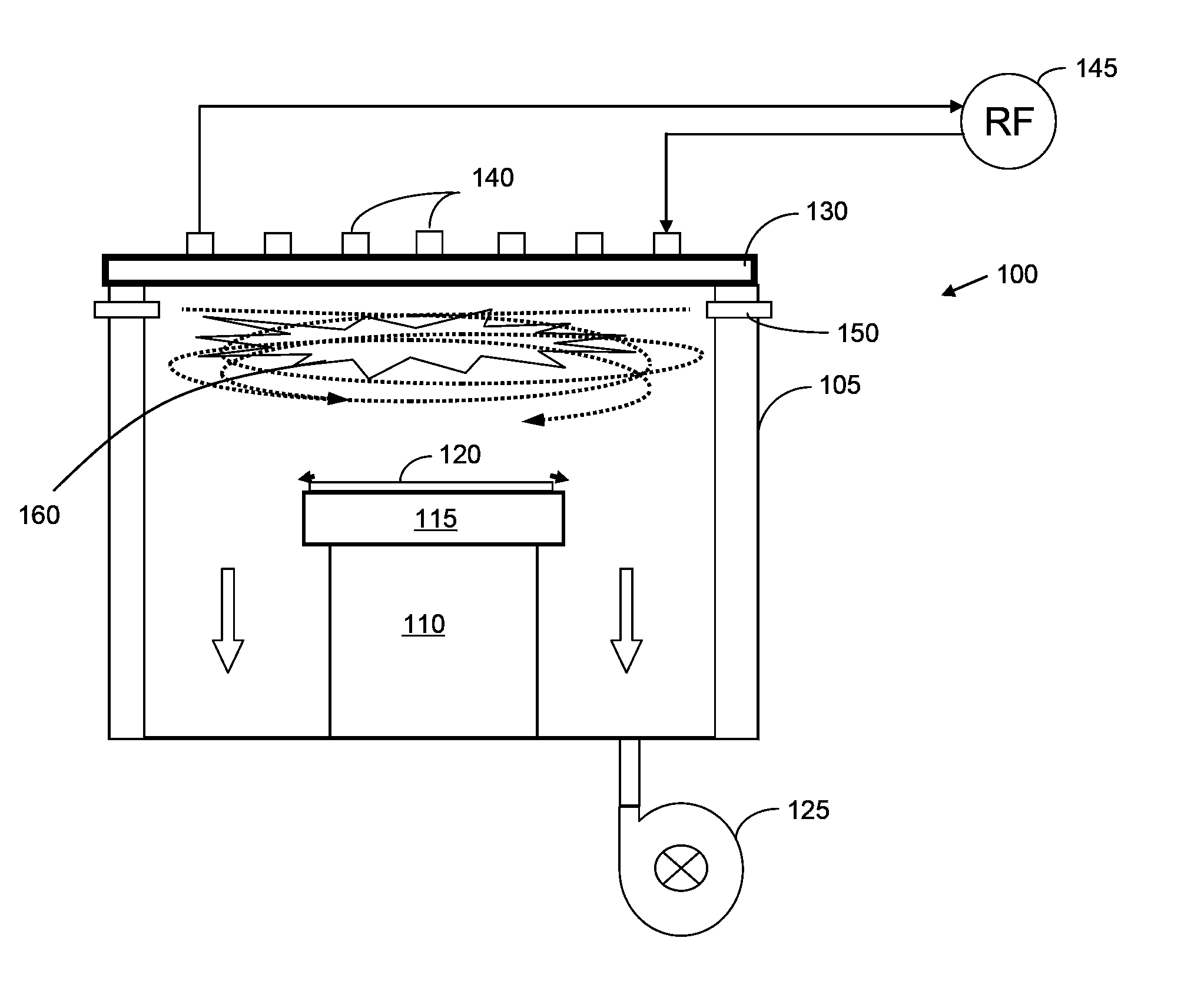

Inductively-coupled torodial plasma source

InactiveUS7166816B1Reduce potential differenceEasy to operateElectric discharge tubesElectric arc lampsEngineeringVoltage source

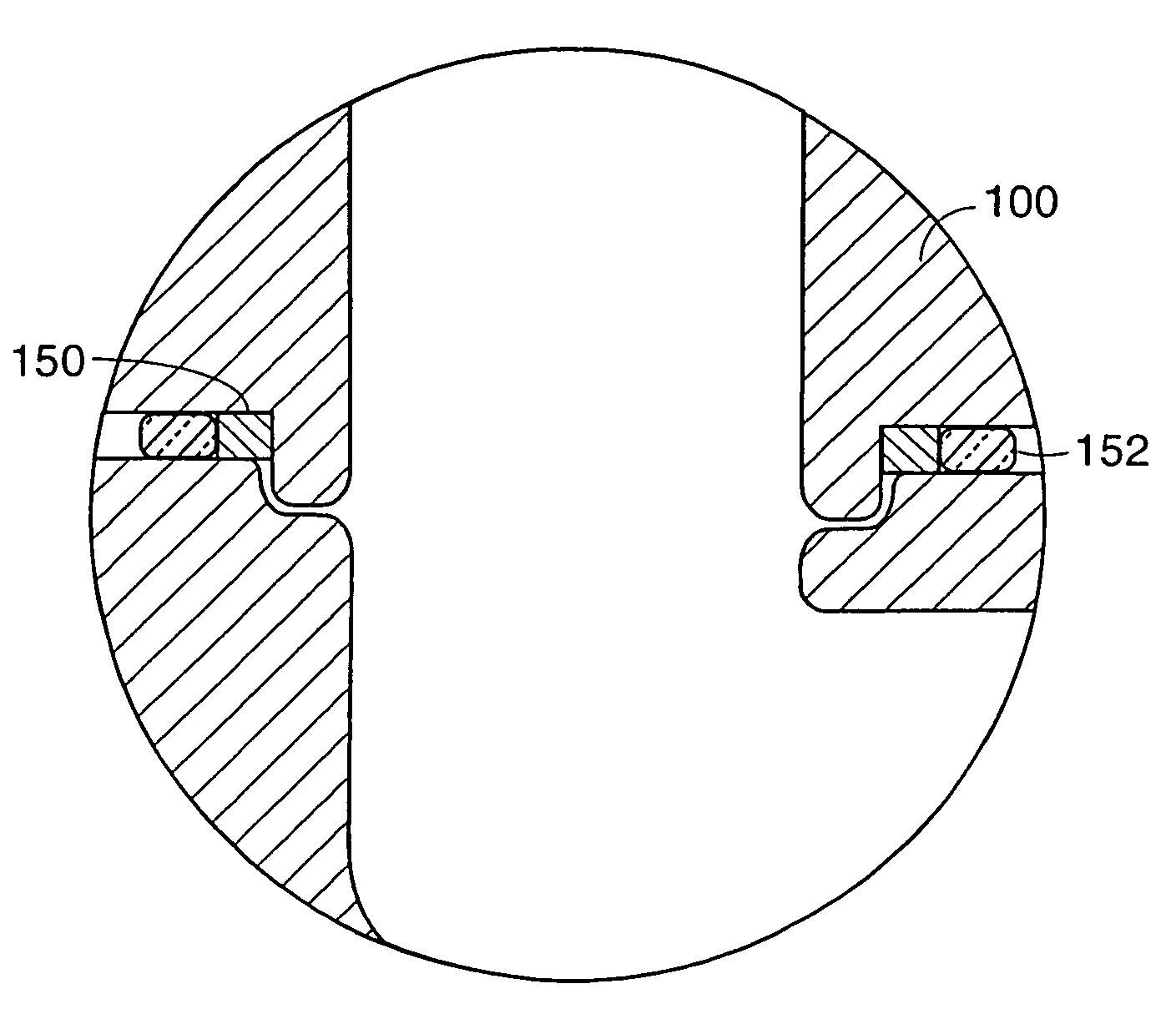

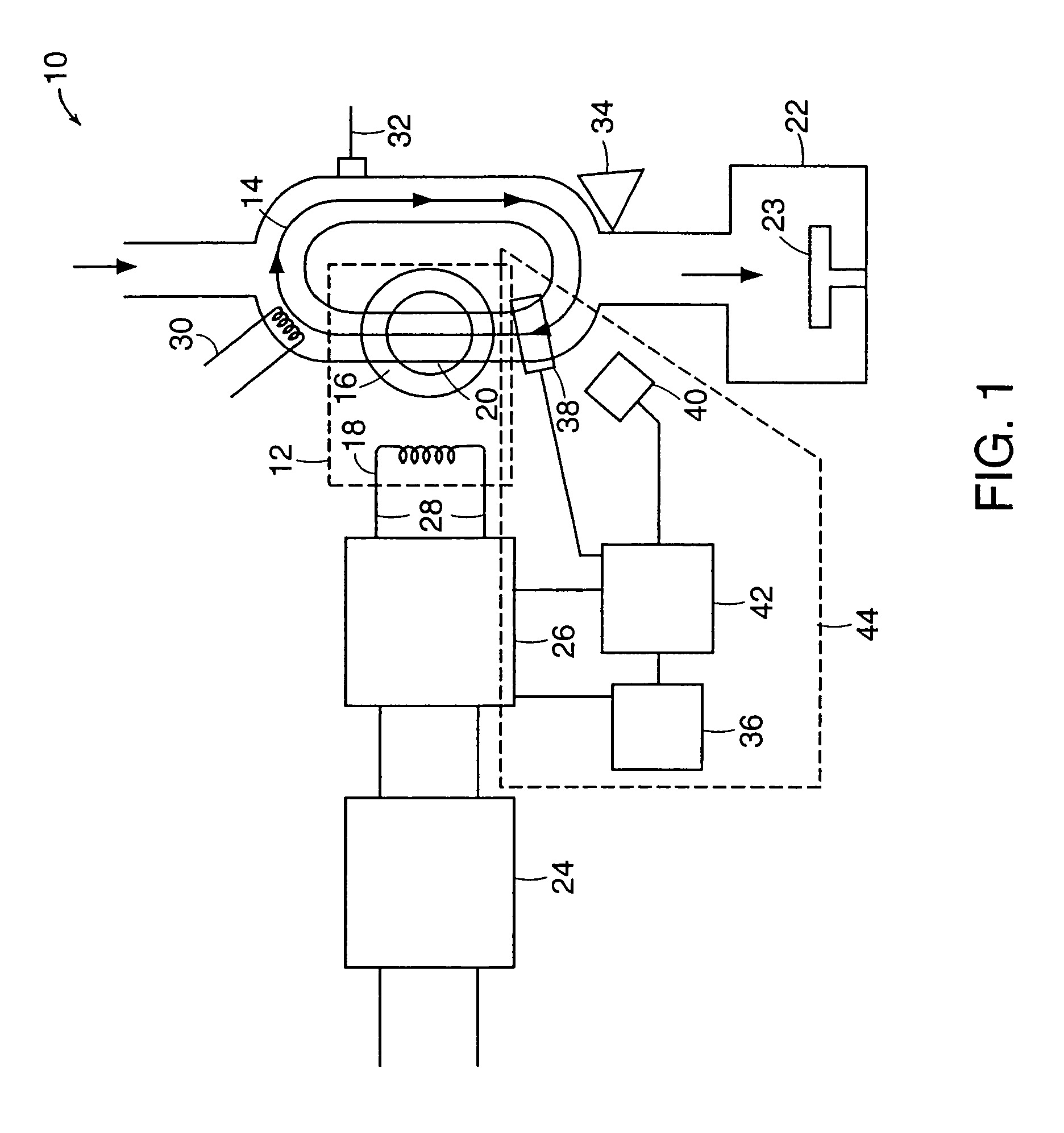

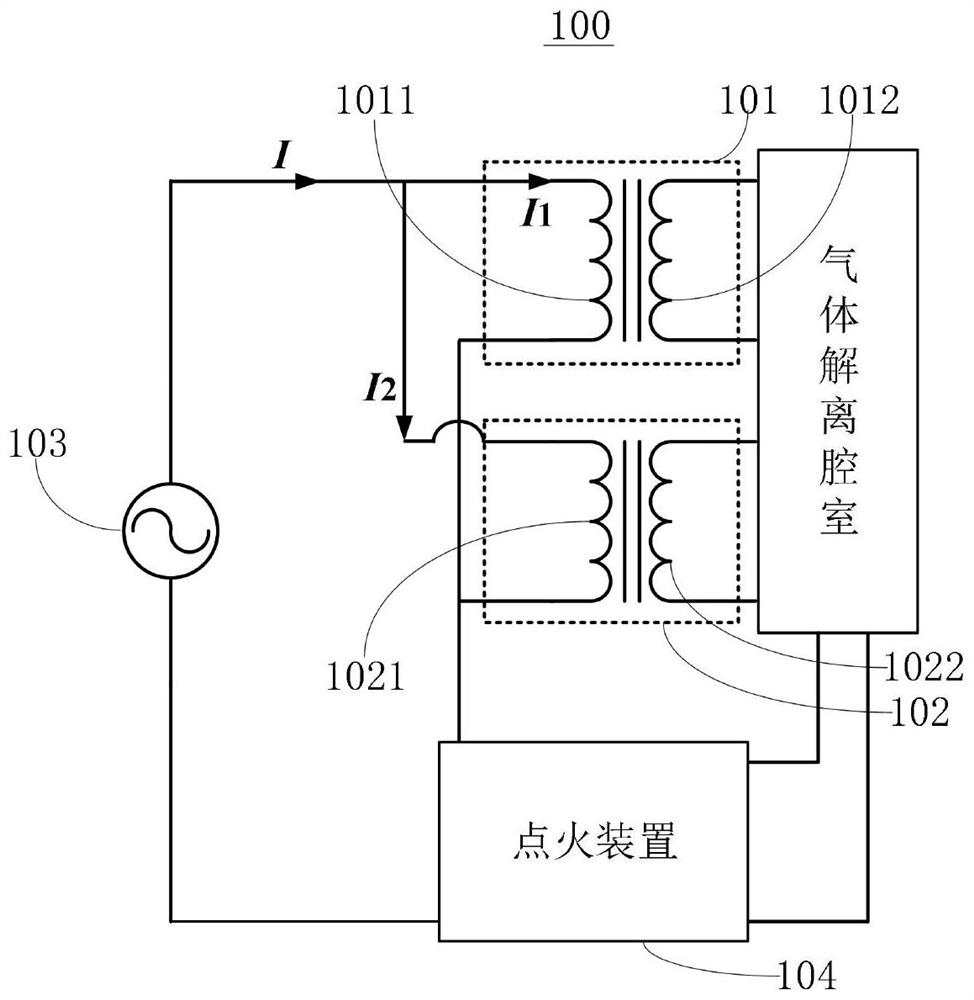

Apparatus for dissociating gases includes a plasma chamber comprising a gas. A first transformer having a first magnetic core surrounds a first portion of the plasma chamber and has a first primary winding. A second transformer having a second magnetic core surrounds a second portion of the plasma chamber and has a second primary winding. A first solid state AC switching power supply including one or more switching semiconductor devices is coupled to a first voltage supply and has a first output that is coupled to the first primary winding. A second solid state AC switching power supply including one or more switching semiconductor devices is coupled to a second voltage supply and has a second output that is coupled to the second primary winding. The first solid state AC switching power supply drives a first AC current in the first primary winding. The second solid state AC switching power supply drives a second AC current in the second primary winding. The first AC current and the second AC current induce a combined AC potential inside the plasma chamber that directly forms a toroidal plasma that completes a secondary circuit of the transformer and that dissociates the gas.

Owner:MKS INSTR INC

Composite solid polymer electrolyte and preparation method thereof

The invention provides a composite solid polymer electrolyte and a preparation method thereof. The polymer electrolyte comprises a high-molecular polymer, carbon quantum dots and an organic lithium salt or organic sodium salt, wherein the high-molecular polymer is selected from one of polyoxyethylene, polyacrylonitrile or polymethyl methacrylate and the like. The preparation method comprises the steps of preparing the carbon quantum dots from organic ketone or organic aldehyde as a raw material and then compounding the carbon quantum dots and high-molecular polymer matrix and the organic lithium / sodium salt. By the composite solid polymer electrolyte, a crystal phase of the polymer matrix in the electrolyte can be effectively reduced, the dissociation rate of the lithium / sodium salt is improved, and the electrochemical properties of the ionic conductivity and the like of the polymer electrolyte are significantly improved.

Owner:湖南国拓新能源科技有限公司

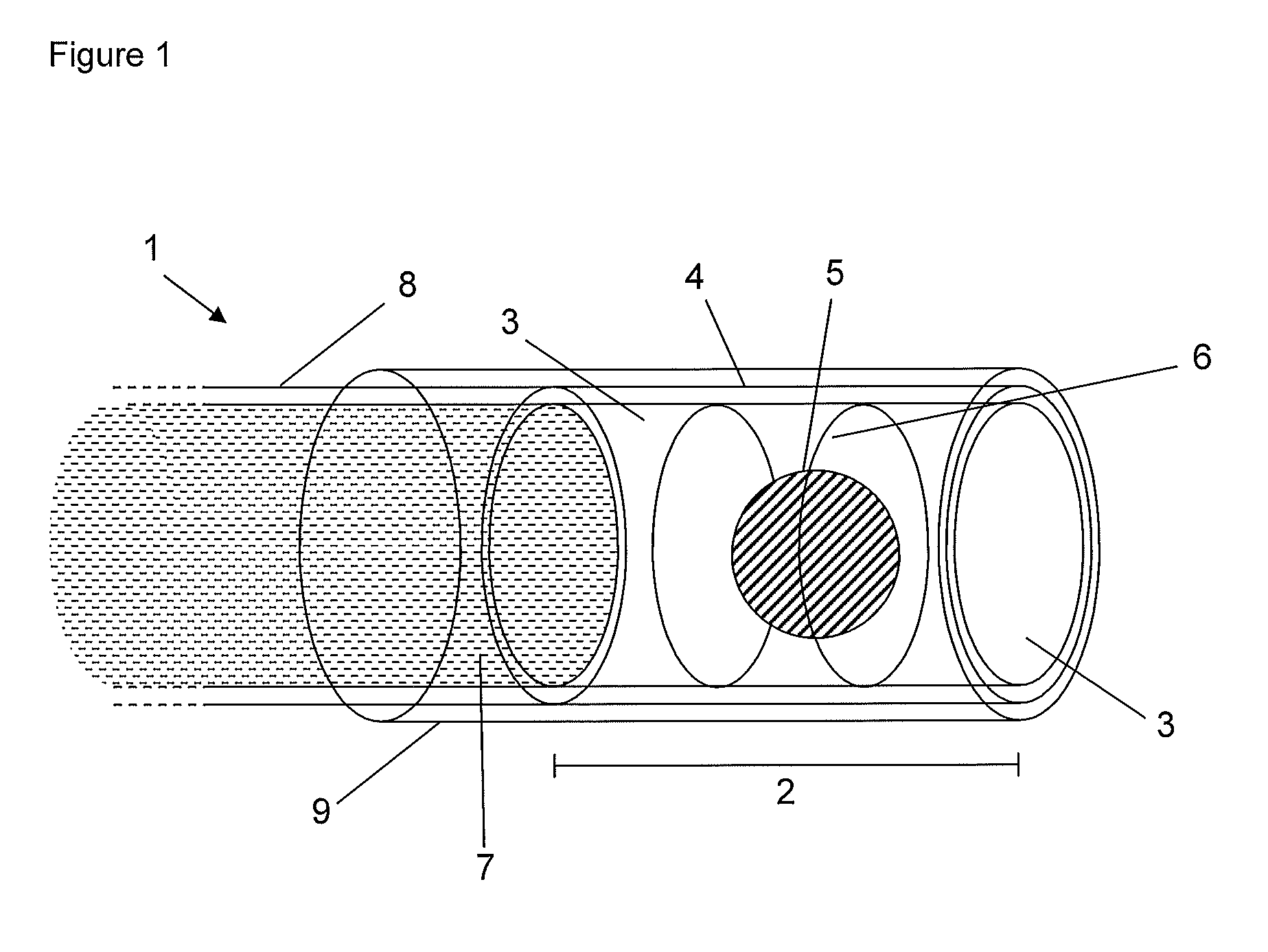

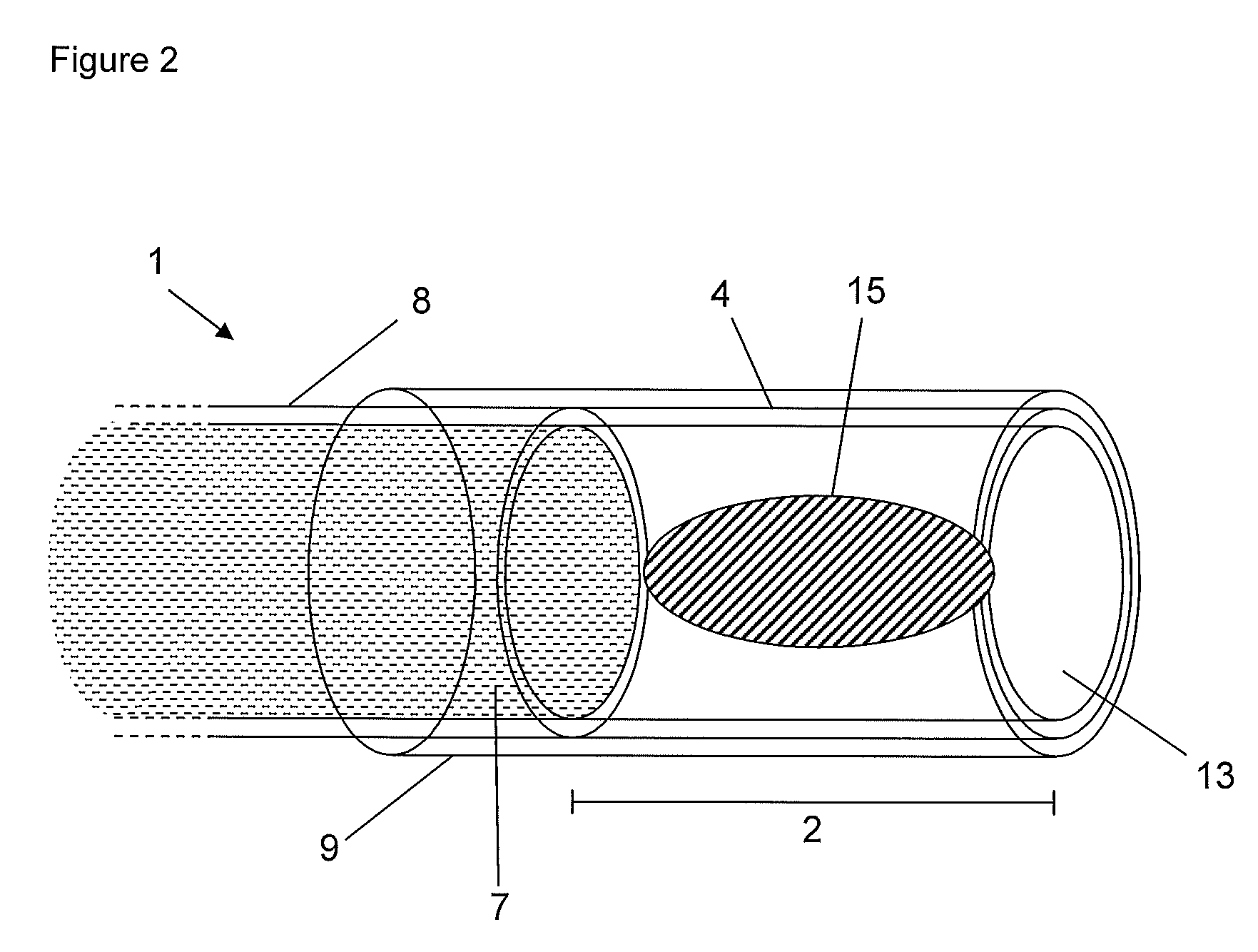

Enhancing the Disintegration and/or Degradation of a Smoking Article

InactiveUS20130047999A1Enhance disintegration and degradationEasily disintegrated and dispersedTobacco treatmentCigar manufactureEngineering

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

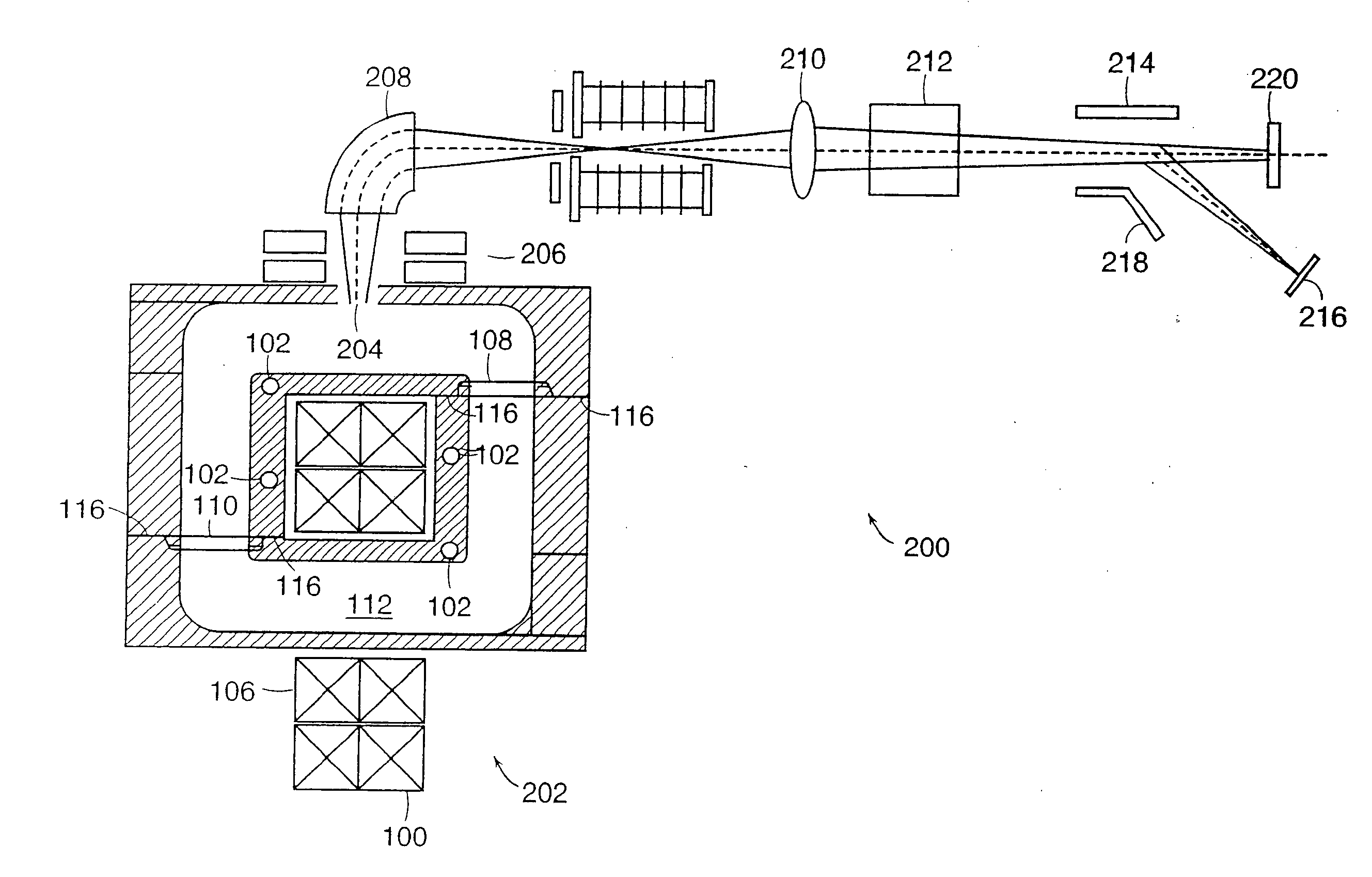

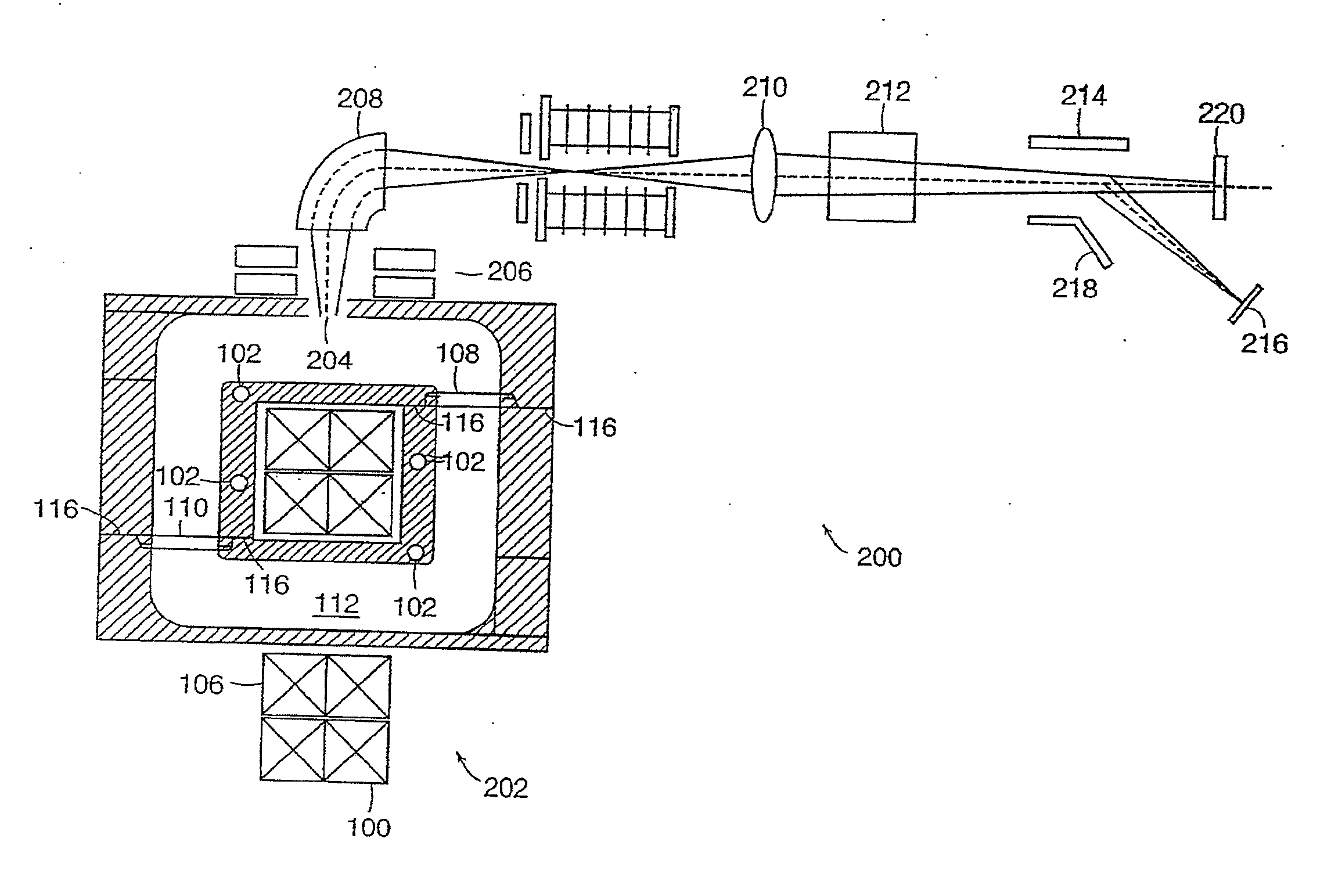

Inductively-coupled toroidal plasma source

InactiveUS20070145018A1Reduce potential differenceEasy to operateElectric discharge tubesElectric arc lampsEngineeringVoltage source

Apparatus for dissociating gases includes a plasma chamber comprising a gas. A first transformer having a first magnetic core surrounds a first portion of the plasma chamber and has a first primary winding. A second transformer having a second magnetic core surrounds a second portion of the plasma chamber and has a second primary winding. A first solid state AC switching power supply including one or more switching semiconductor devices is coupled to a first voltage supply and has a first output that is coupled to the first primary winding. A second solid state AC switching power supply including one or more switching semiconductor devices is coupled to a second voltage supply and has a second output that is coupled to the second primary winding. The first solid state AC switching power supply drives a first AC current in the first primary winding. The second solid state AC switching power supply drives a second AC current in the second primary winding. The first AC current and the second AC current induce a combined AC potential inside the plasma chamber that directly forms a toroidal plasma that completes a secondary circuit of the transformer and that dissociates the gas.

Owner:MKS INSTR INC

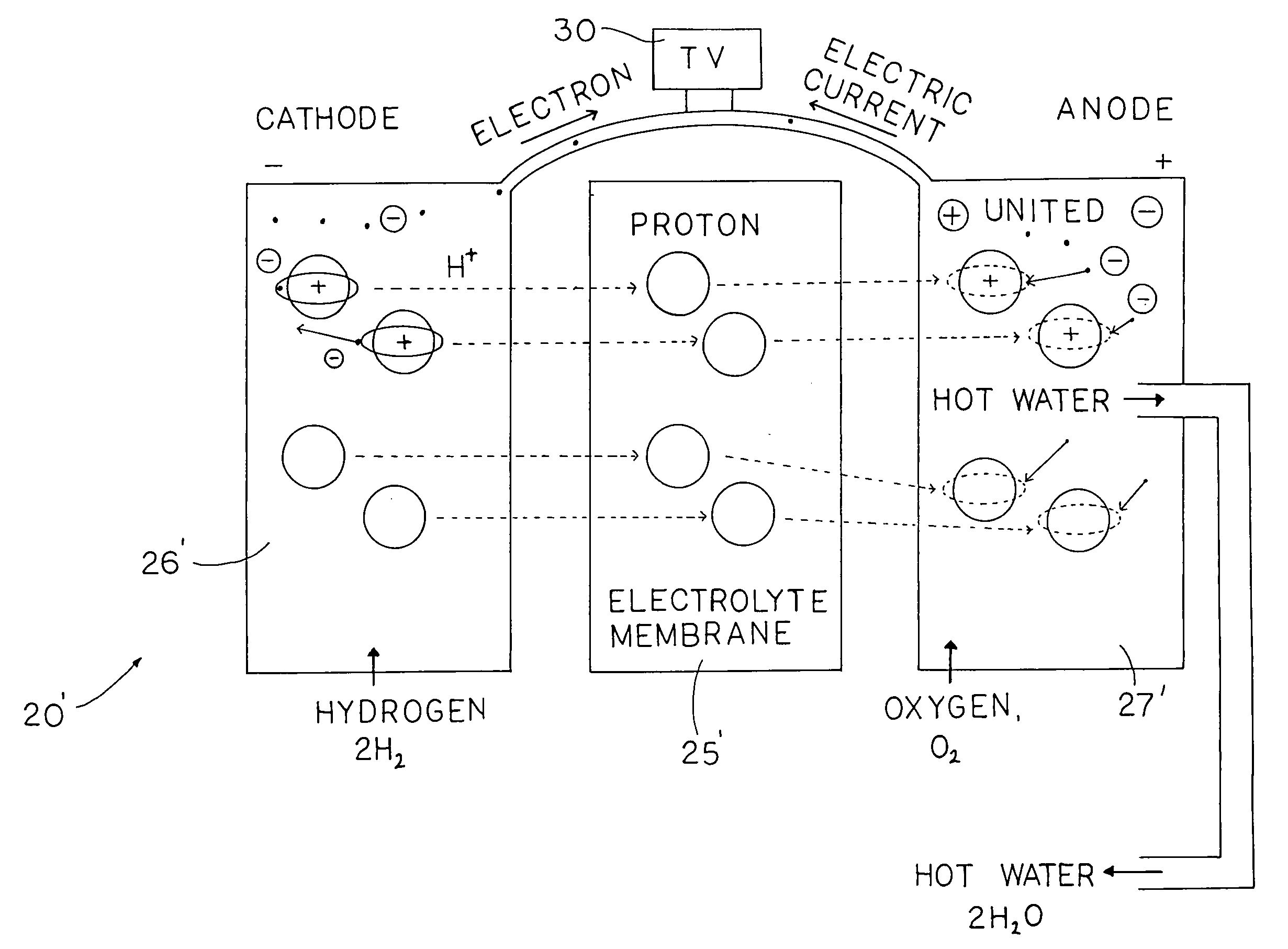

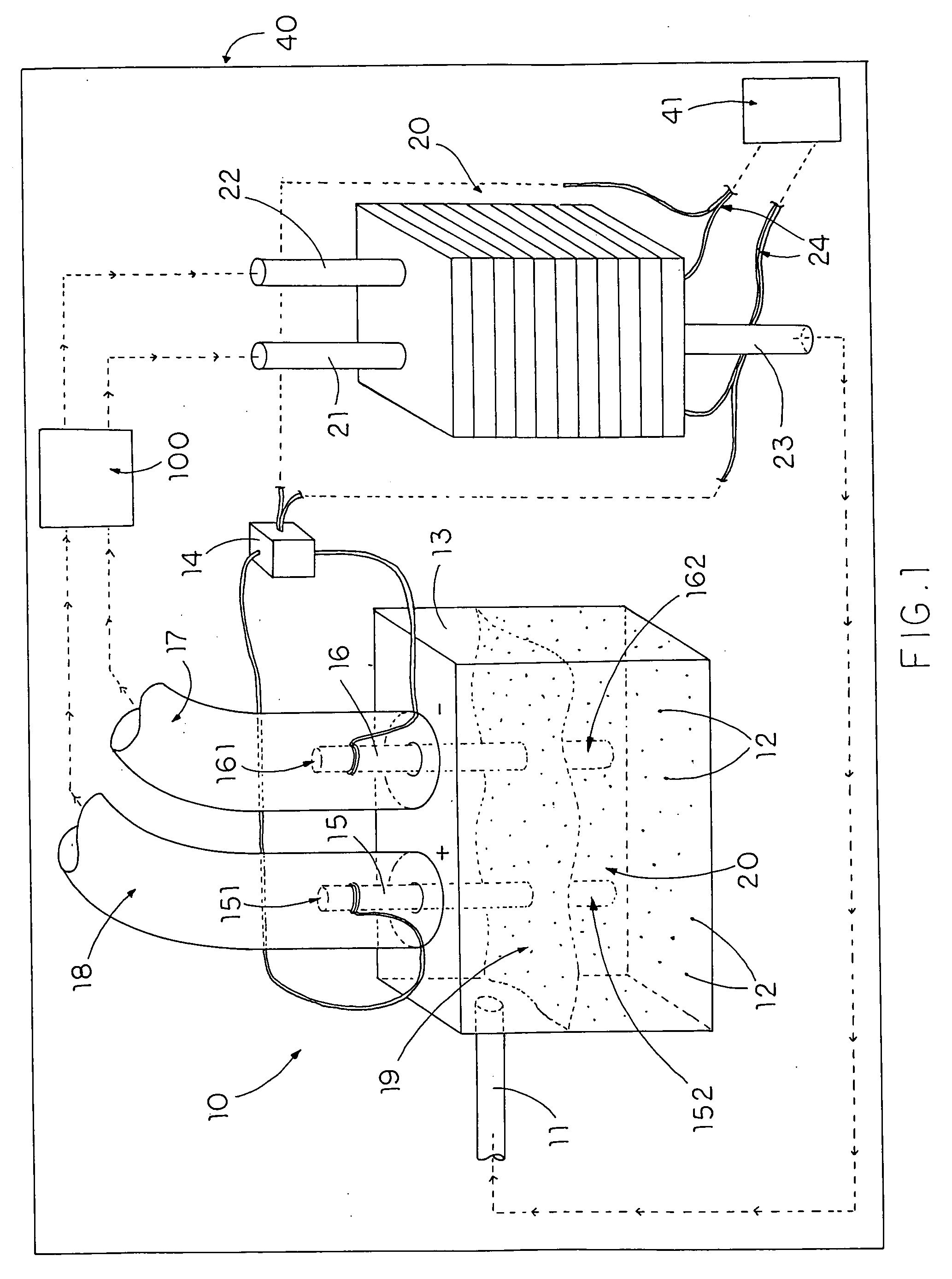

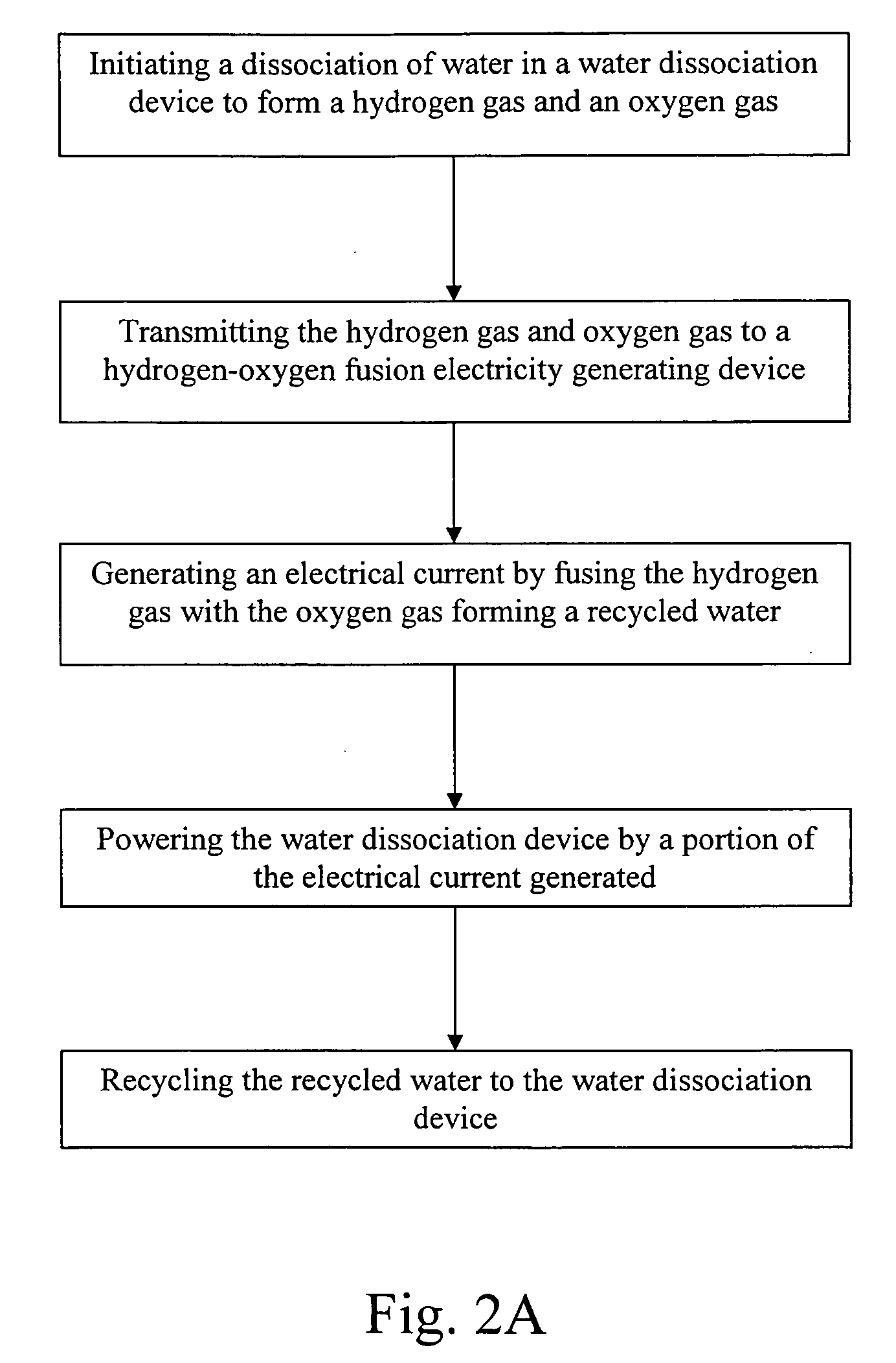

Inverse recycle power system

InactiveUS20060194086A1Low costMinimal presenceRegenerative fuel cellsFuel cell auxillariesFuel cellsHydrogen

An inverse-recycle power system processes a dissociation of water into a hydrogen gas and an oxygen gas and a fusion of hydrogen gas and oxygen gas forming a recycled water while generating an electric current. The electric current is then used for powering any electrical devices, and more particularly, automobiles. The inverse-recycle power system can self-sustain, with an occasional need of water refill. At the end of the system, water is regenerated and recycled, and a portion of the electric current is used for powering the dissociation of water. The dissociation of water is carried out by an electrolysis process, which is enhanced by the addition of a dissociation catalyst that would be regenerated and recycled after assisting water to dissociate in to hydrogen gas and oxygen gas. The fusion of hydrogen gas and oxygen gas to generate the electric current is essentially carried out by a fuel cell system.

Owner:HSU KUAI TENG

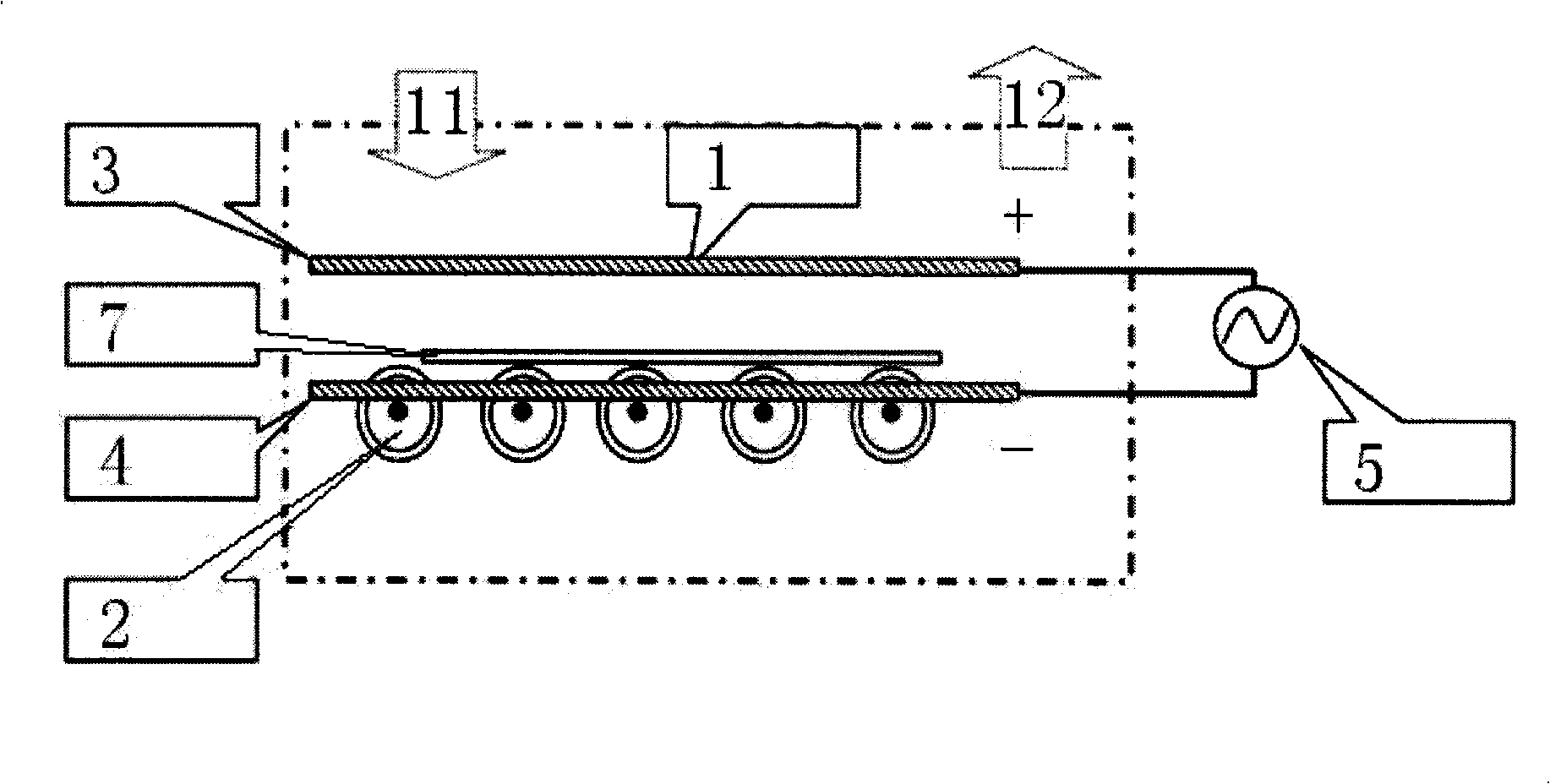

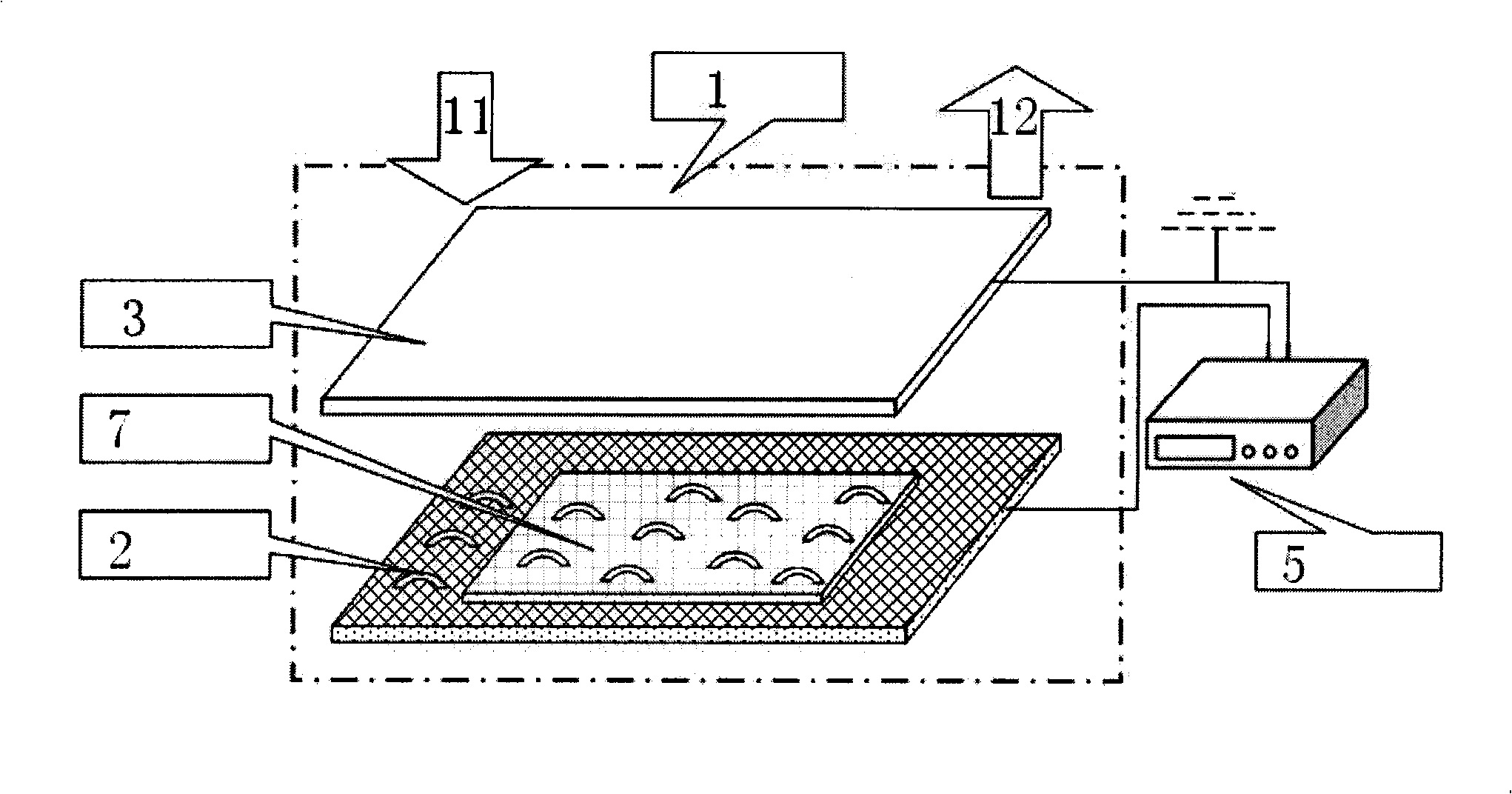

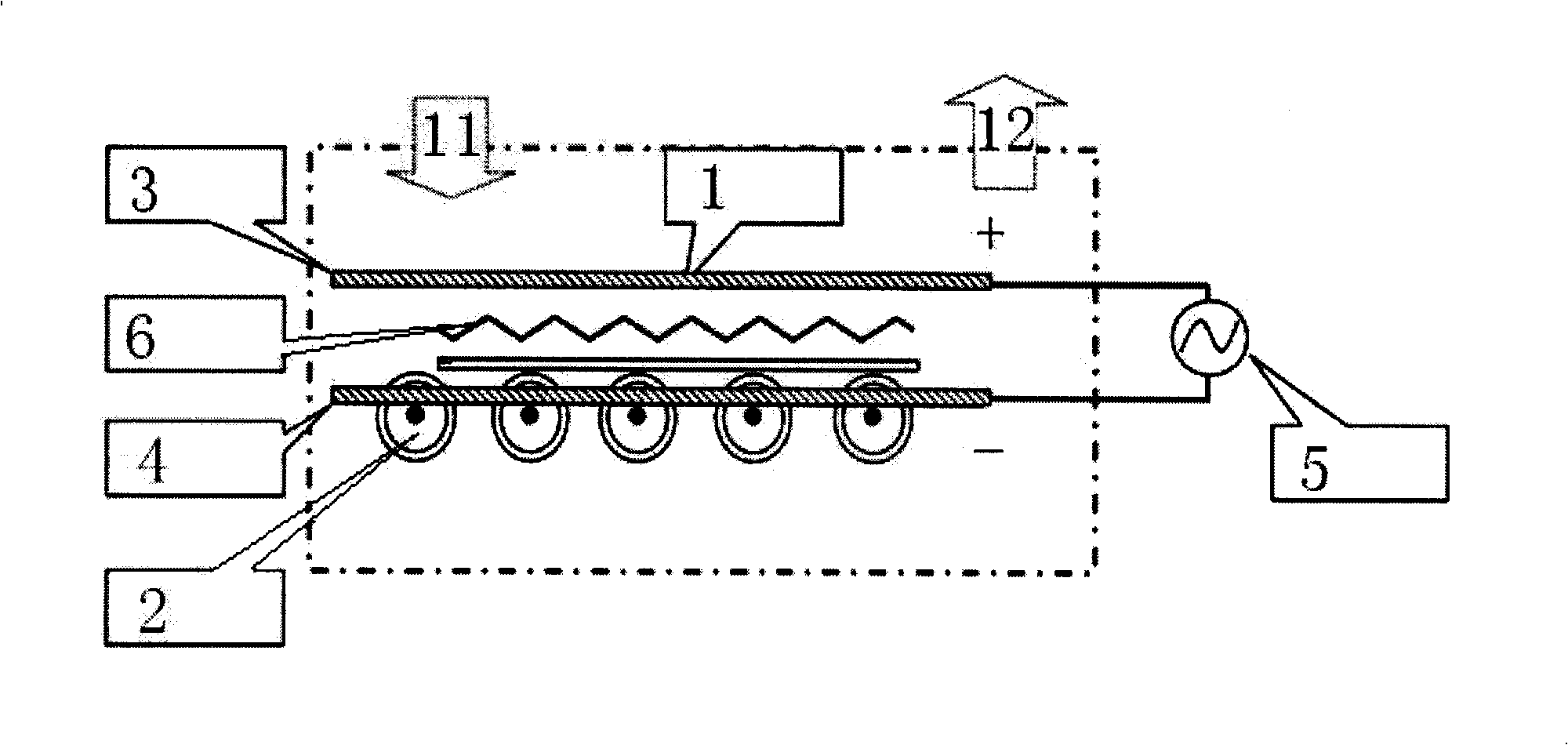

Plasma surface cleaning apparatus

InactiveCN101402095ARemove completelyImprove surface cleanlinessCleaning processes and apparatusEngineeringVacuum chamber

The invention discloses a plasma surface cleaning device, which comprises at least one vacuum cavity, a transmission device and a pair of metal plate, wherein the vacuum cavity is provided with an air intake and an exhaust port, the transmission device is arranged in the vacuum cavity, and the metal plate is arranged above and below the transmission device and is connected with positive and negative poles of a biasing power. The cleaning device can remove pollutant remained on plated pieces (glass) effectively and can avoid secondary pollution of the plasma surface without contacting air after cleaning.

Owner:上海拓引数码技术有限公司

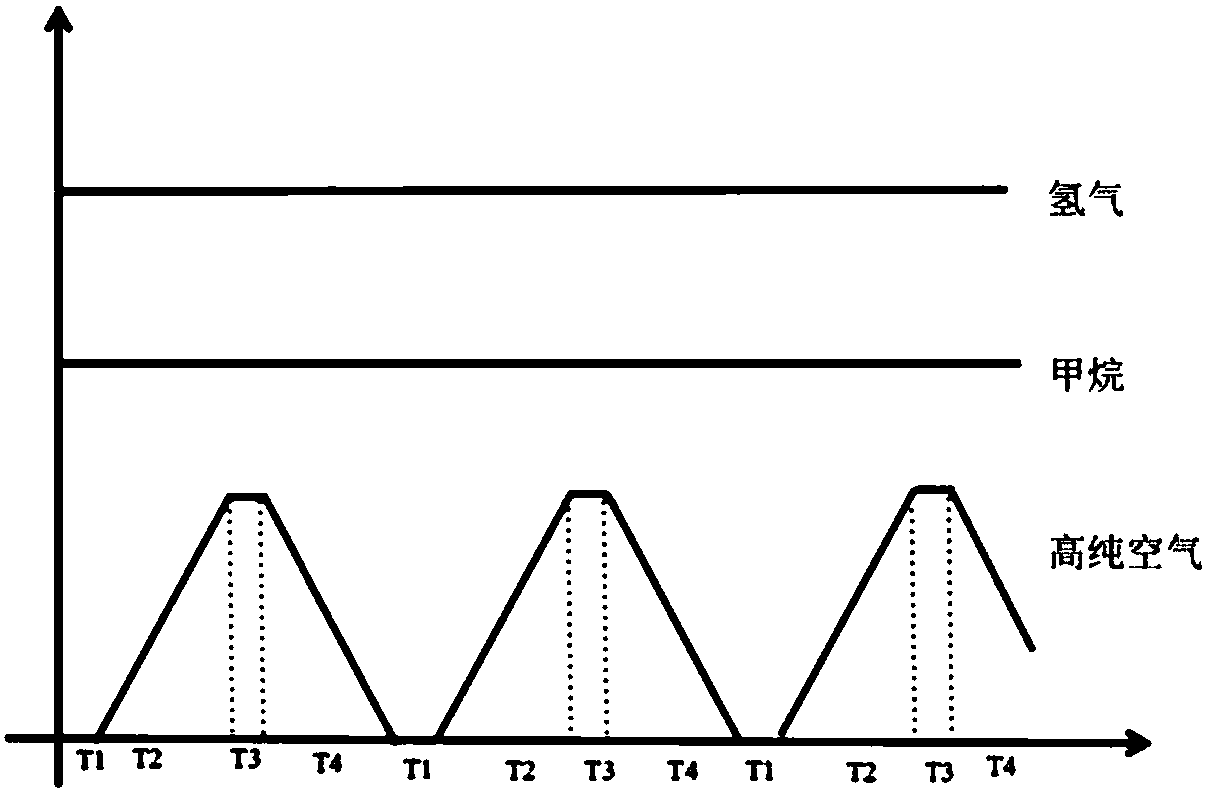

Gradient monocrystalline diamond and preparation method thereof

ActiveCN107740184AFast growthHigh hardnessPolycrystalline material growthFrom chemically reactive gasesHydrogenNitrogen

The invention relates to the field of growth of monocrystalline diamonds through a microwave plasma chemical vapor deposition method and in particular relates to a gradient monocrystalline diamond anda preparation method thereof. Microwave plasma chemical vapor deposition equipment is adopted and high-purity air is introduced in a hydrogen and methane mixed gas source according to a continuous gradient concentration, so as to realize alternating deposition of a high-quality monocrystalline diamond layer without nitrogen and a nitrogen-containing diamond layer; then the gradient monocrystalline diamond with high quality, high strength and good toughness is prepared.

Owner:湖北碳六科技有限公司

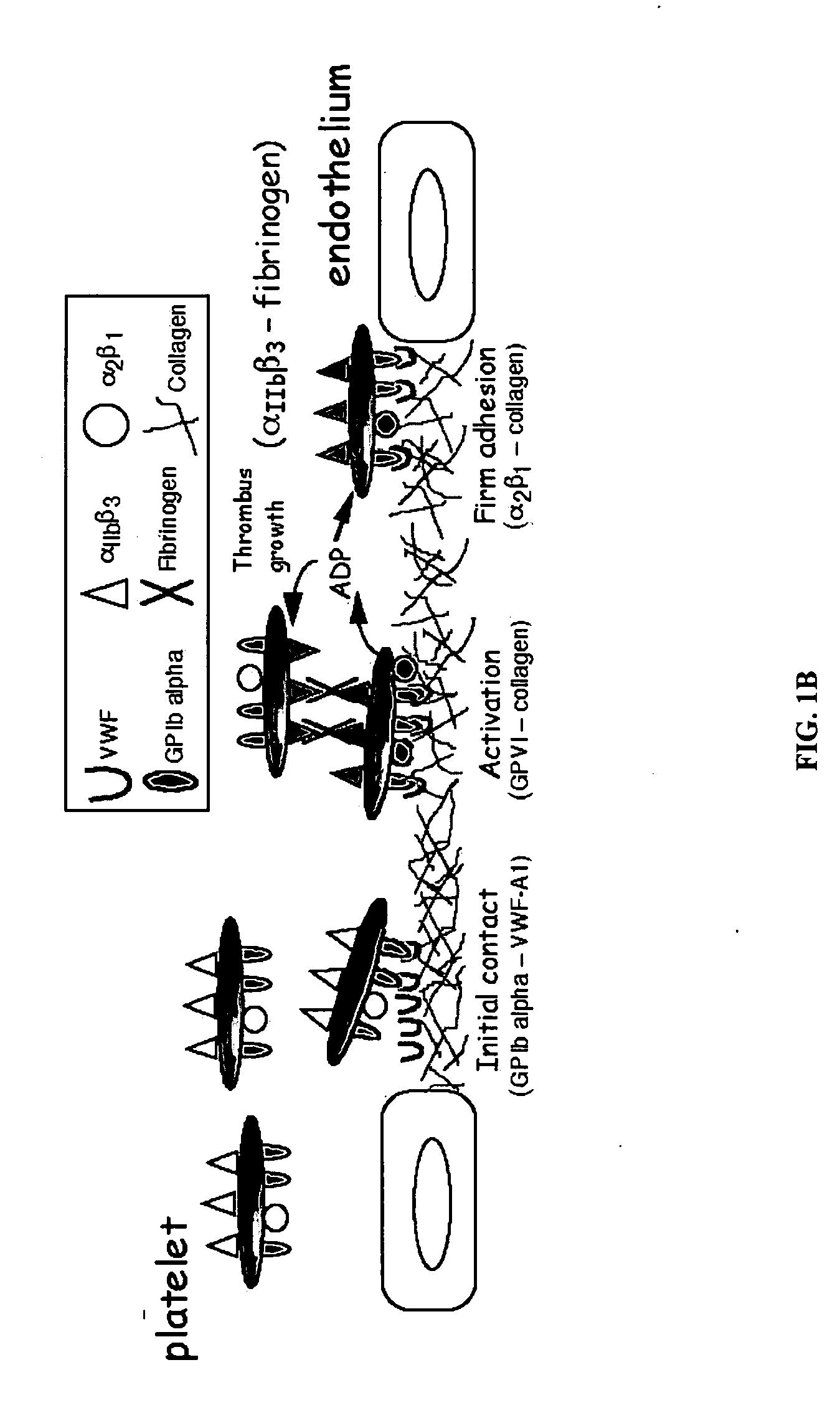

Methods for testing Anti-thrombotic agents

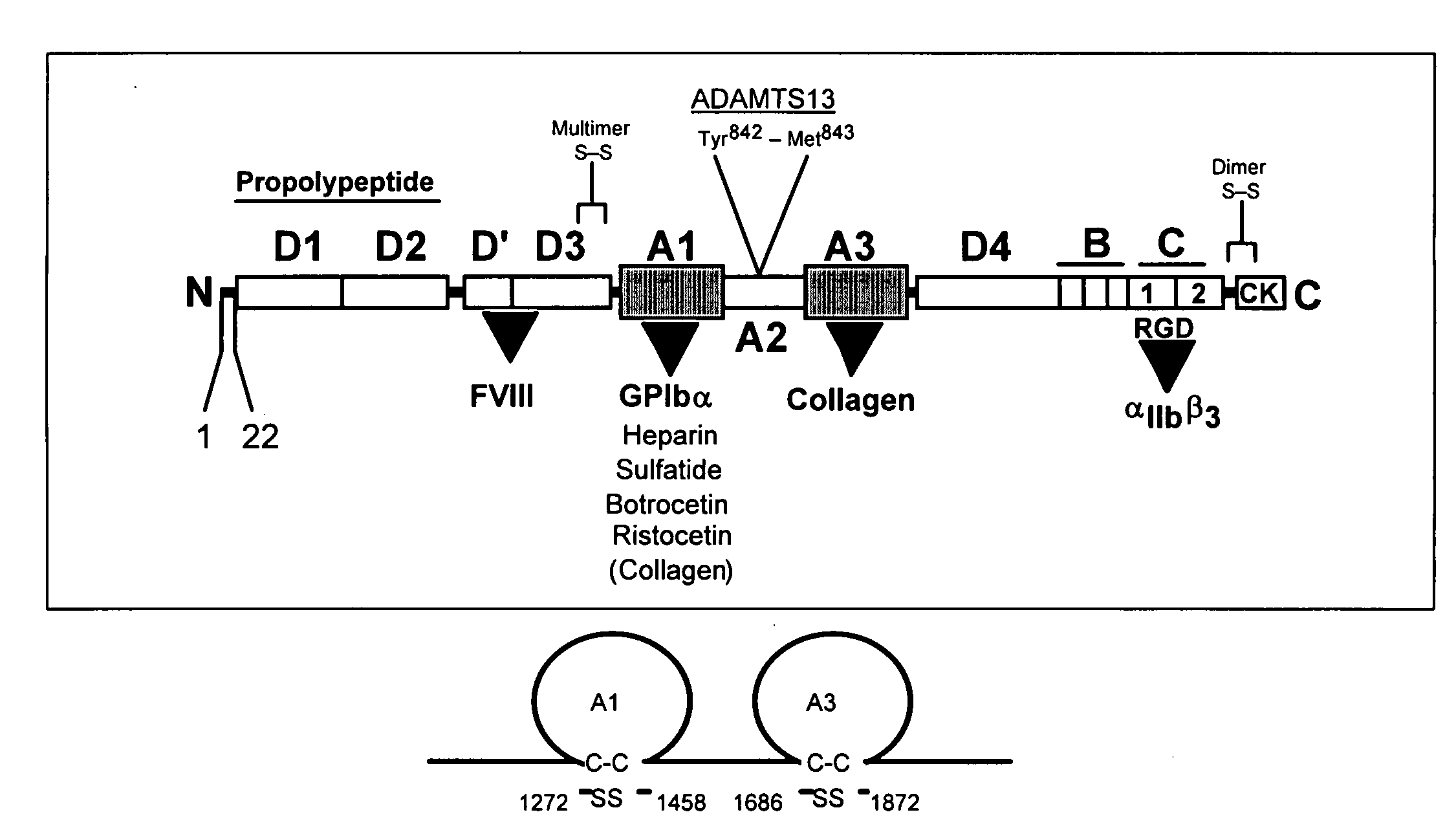

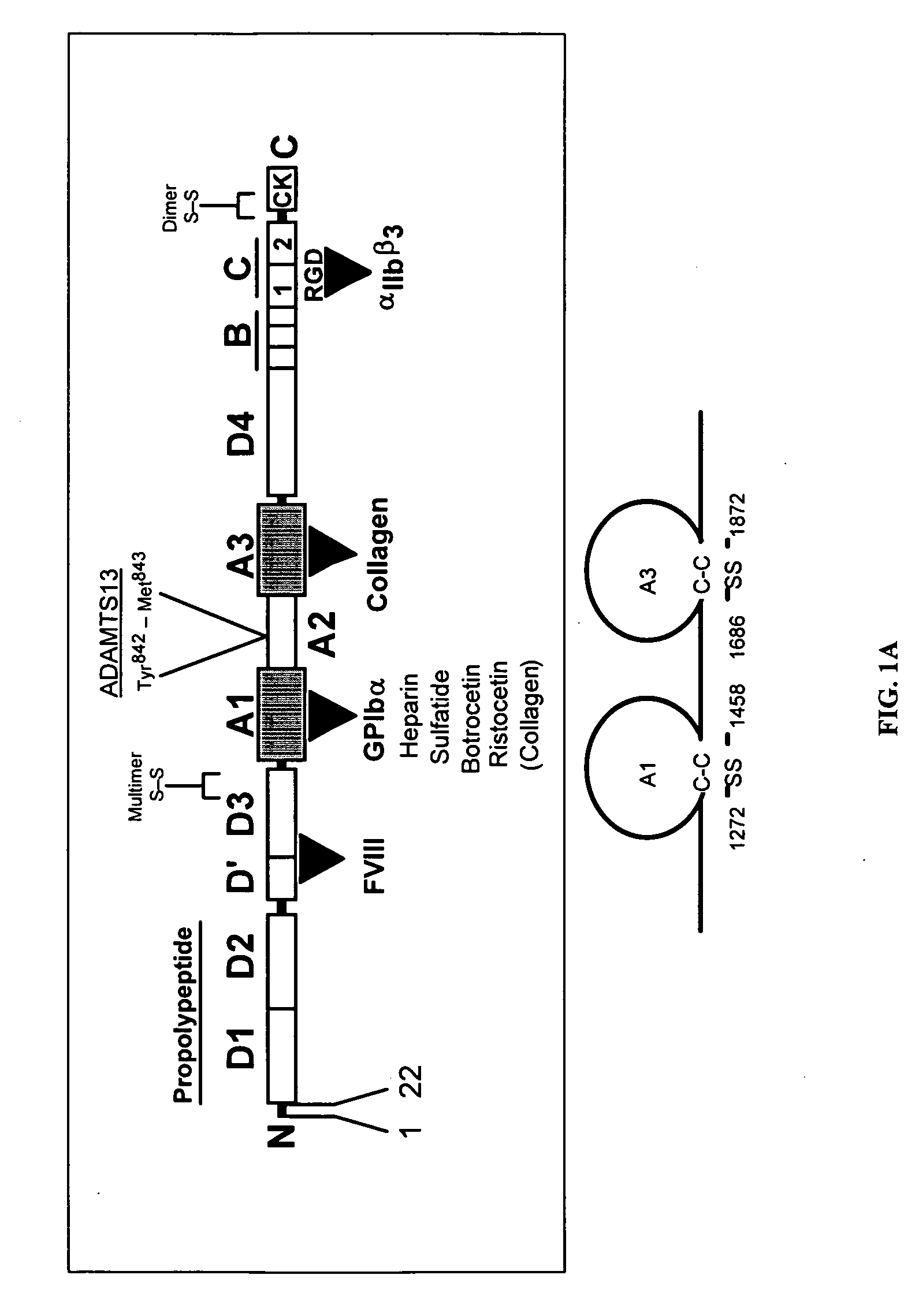

InactiveUS20090202429A1Reduce attachmentSmall shapeFactor VIICompound screeningHuman animalFactor VIII vWF

The invention provides a transgenic non-human animal expressing von Willebrand Factor A1 protein containing at least one mutation selected from the group consisting of: 1263P>S, 1269N>D, 1274K>R, 1287M>R, 1302G>D, 1308H>R, 1313R>W, 1314I>V, 1326R>H, 1329L>I, 1330E>G, 1333A>D, 1344T>A, 1347I>V, 1350T>A, 1370G>S, 1379H>R, 1381T>A, 1385T>M 1391P>Q, 1394A>S, 1397L>F, 1421S>N, 1439L>V, 1442G>S, 1449R>Q, 1466A>P, 1469Q>L, 1472Q>H, 1473V>M, 1475H>Q, 1479S>G, and any combination thereof.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

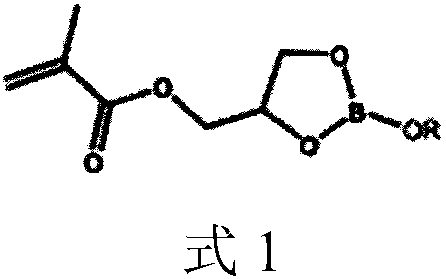

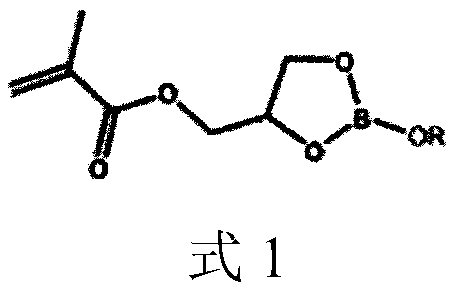

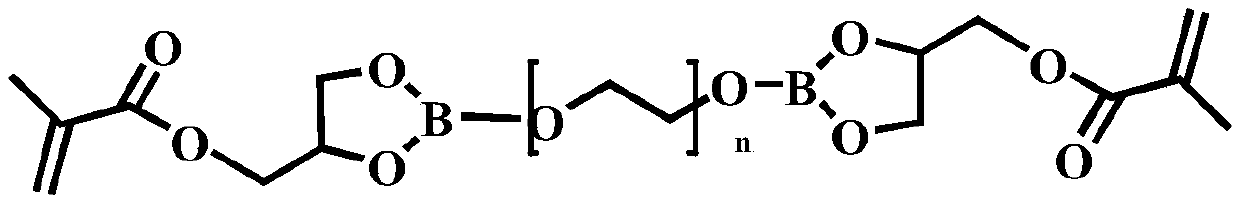

Preparation method of crosslinked polymer electrolyte, semisolid polymer battery and preparation method thereof

ActiveCN109575187AExcellent performanceSimple processSolid electrolytesLi-accumulatorsElectro conductivityIn situ polymerization

The invention provides a preparation method of crosslinked polymer electrolyte, a semisolid polymer battery and a preparation method thereof. A cyclic borate with alkenyl groups at two terminals is used as a crosslinker; a polymer monomer and the like are subjected to in-situ polymerization on a support material to obtain the crosslinked polymer electrolyte. The preparation method of the crosslinked polymer electrolyte is simple; the prepared polymer electrolyte has small resistance and good compatibility with electrodes, and has good mechanical properties and high electrical conductivity andtransport number; a polymer battery electrolyte assembly with the polymer electrolyte has good stability and rate performance.

Owner:广东聚圣科技有限公司

Method and Apparatus for Processing Metal Bearing Gases

InactiveUS20120160059A1Reduce potential differenceReducing and eliminating plasma channel surface erosionCyanogen compoundsNitrogen compoundsMetallic materialsNitride

A method and apparatus for processing metal bearing gases involves generating a toroidal plasma in a plasma chamber. A metal bearing gas is introduced into the plasma chamber to react with the toroidal plasma. The interaction between the toroidal plasma and the metal bearing gas produces at least one of a metallic material, a metal oxide material or a metal nitride material.

Owner:MKS INSTR INC

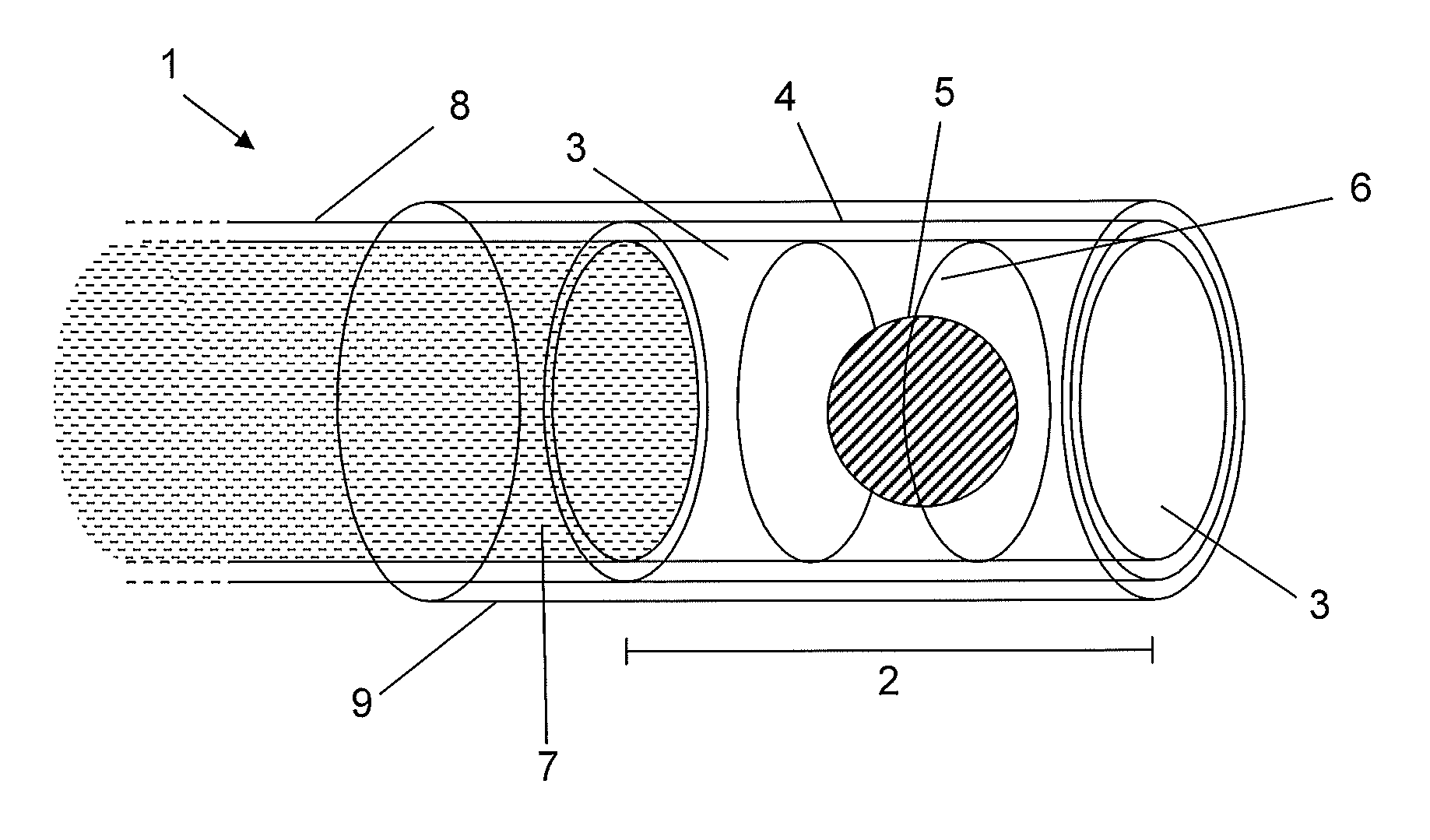

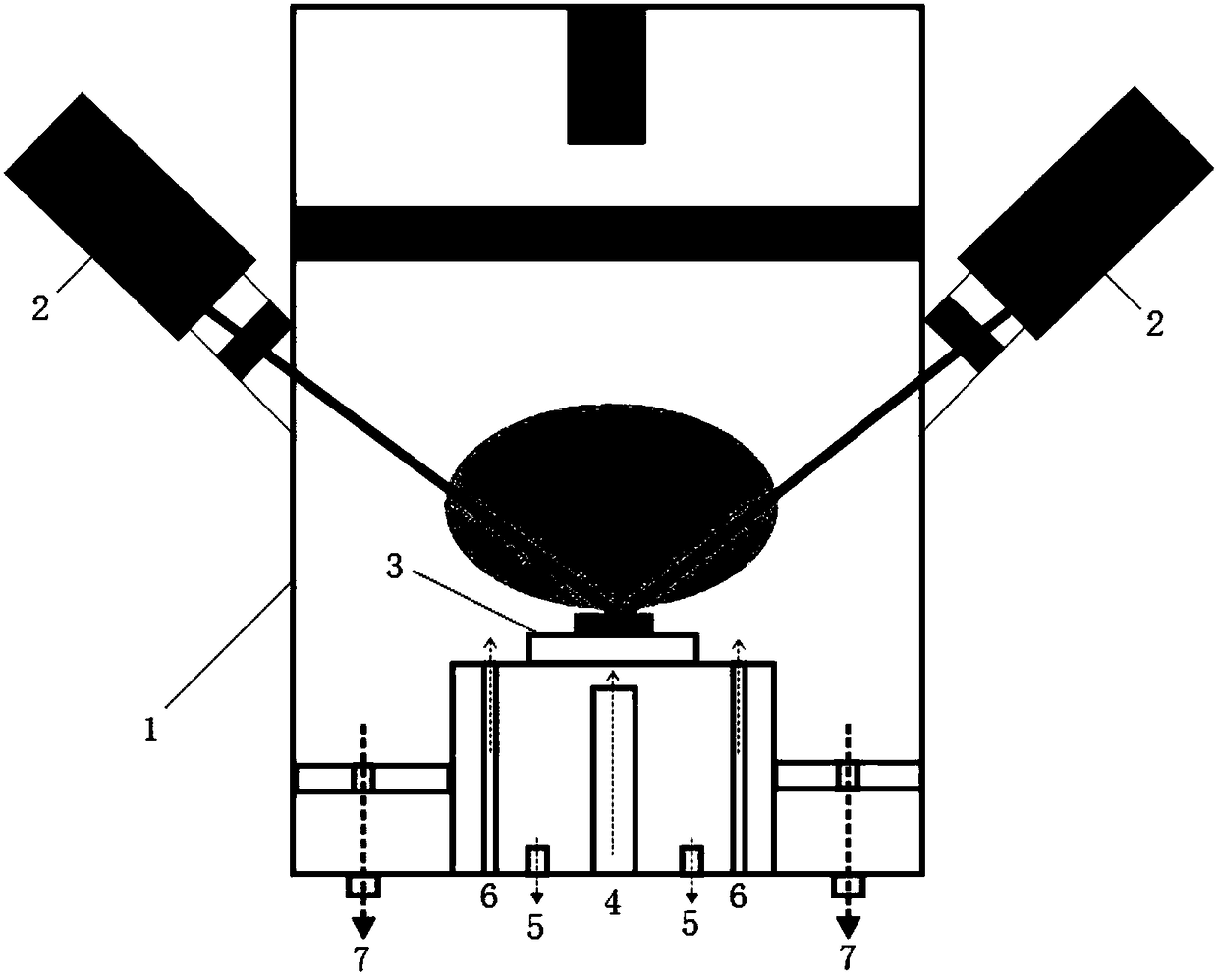

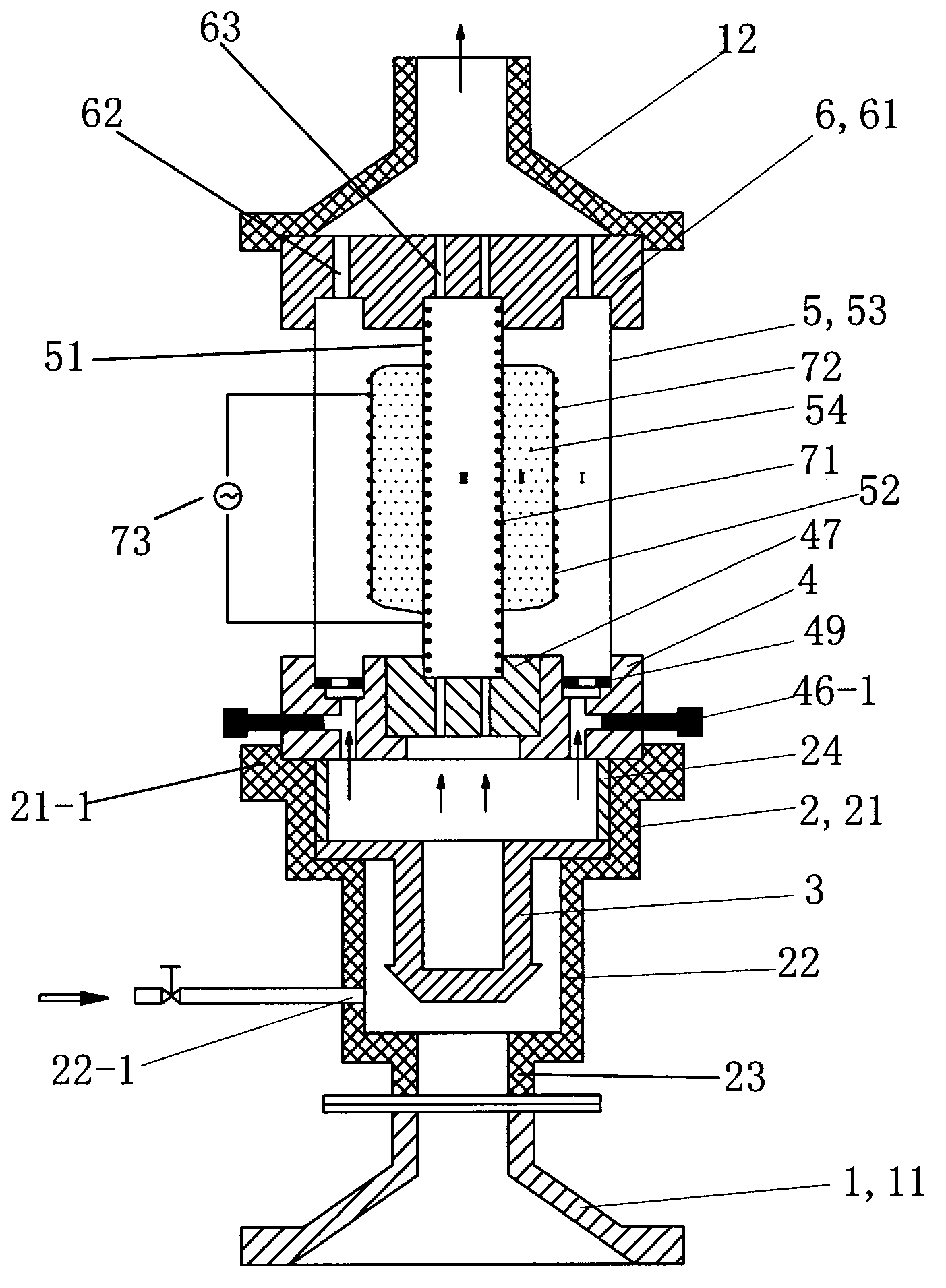

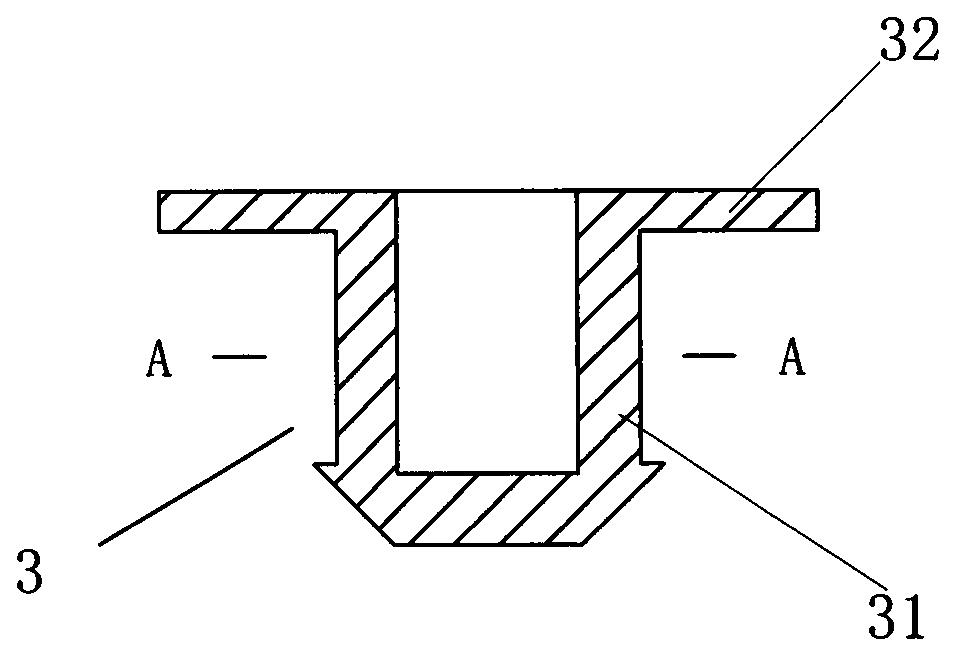

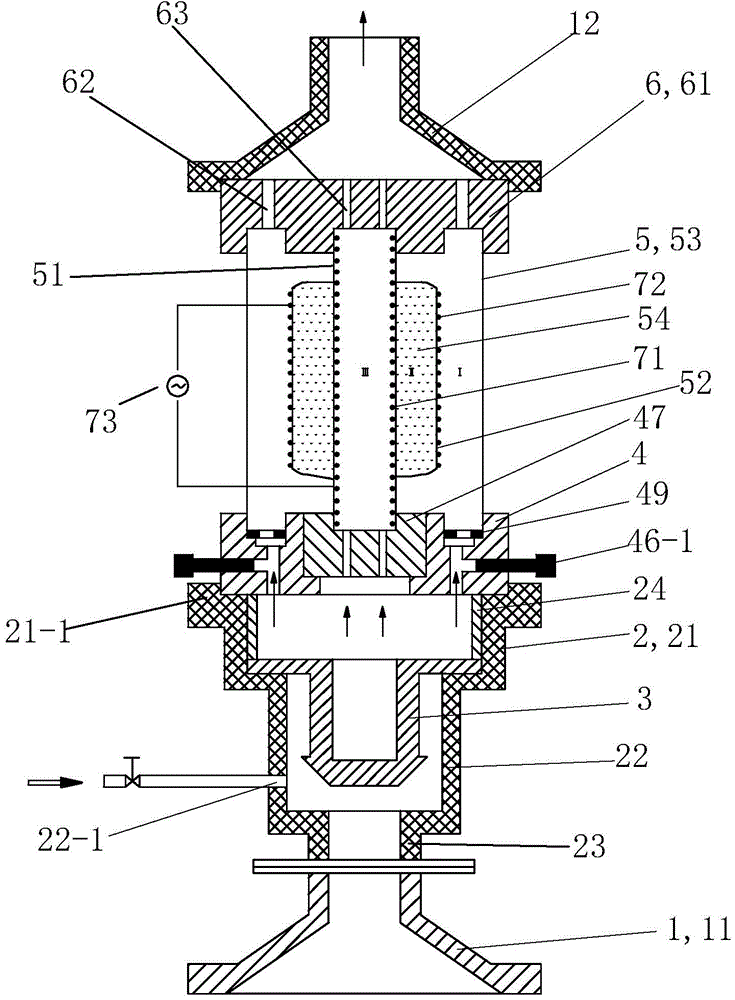

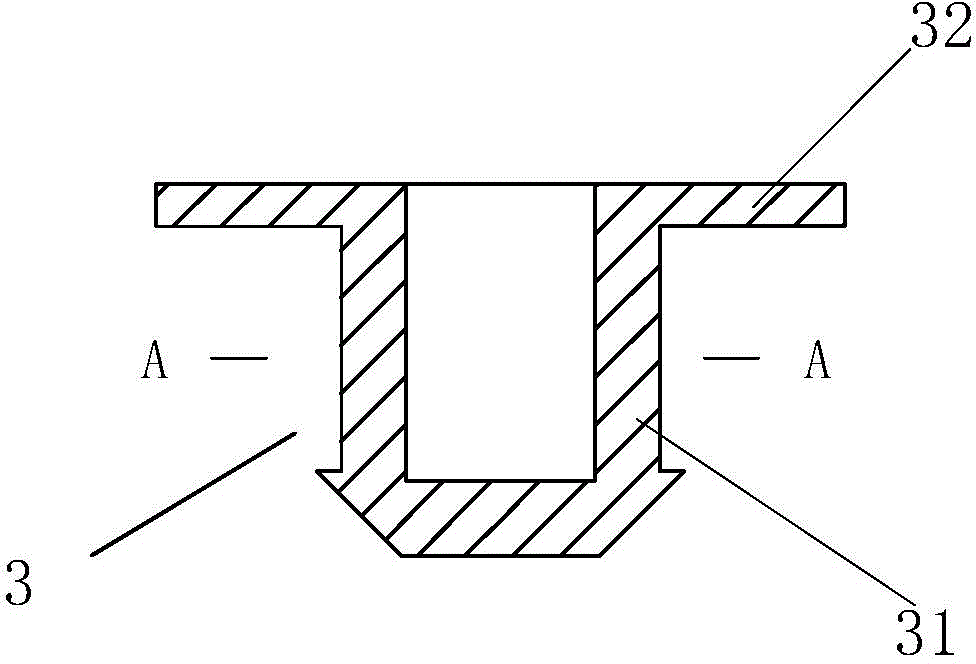

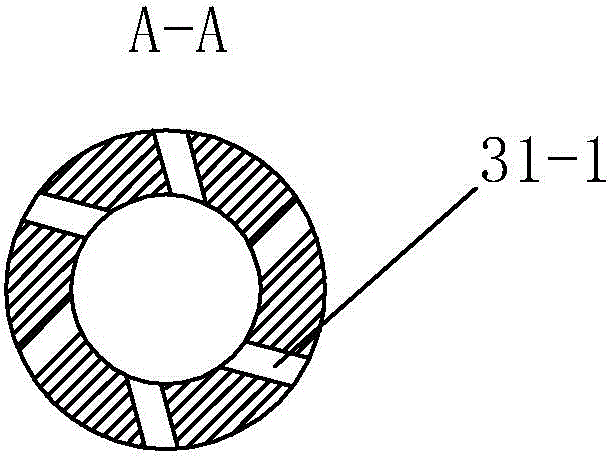

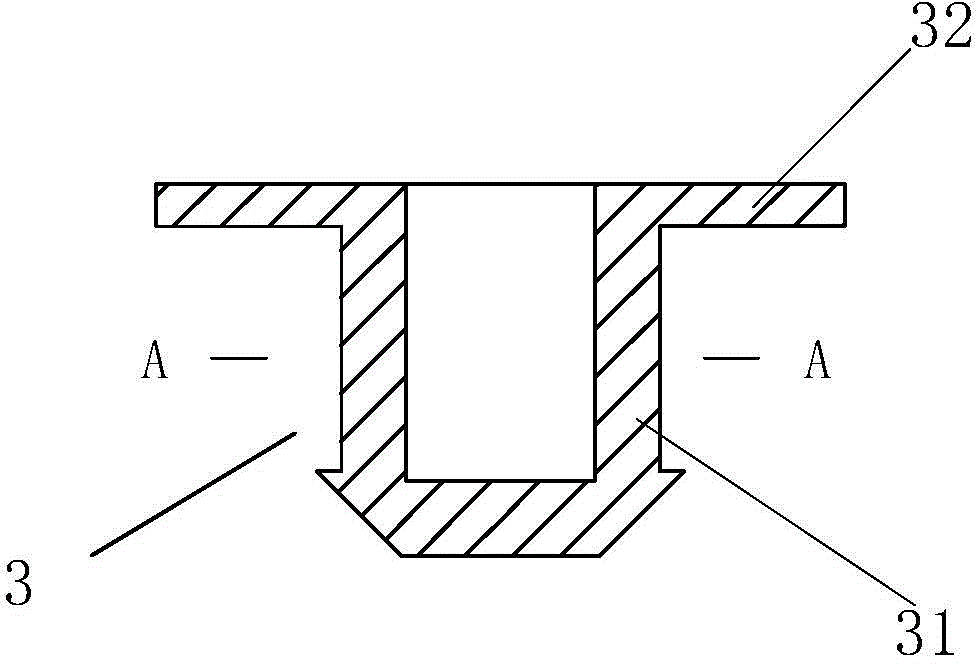

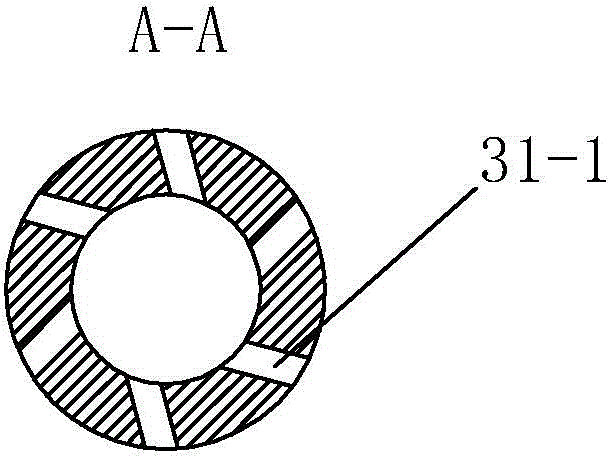

Device and method for preparing single crystal diamonds by laser enhanced plasma CVD

ActiveCN108251892AHigh densityIncrease dissociation ratePolycrystalline material growthFrom chemically reactive gasesMicrowaveSingle crystal

The invention discloses a device and method for preparing single crystal diamonds by laser enhanced plasma CVD. The device comprises plasma CVD equipment and laser equipment, wherein more than 1 set of laser equipment is respectively positioned on the outside of a cylindrical cavity of the plasma CVD equipment, laser emitted by the laser equipment can irradiate onto a substrate table positioned inthe cavity of the plasma CVD equipment; the substrate table is positioned in the middle of the cavity of the plasma CVD equipment, a cooling water circulation system is arranged at the lower part ofthe substrate table and comprises a cooling water inlet and a cooling water outlet; and a raw material gas inlet and an extraction opening are formed in the bottom of the cavity of the plasma CVD equipment. The method combines microwave energy (or electric energy) with laser energy and improves the energy of plasma and the gas dissociation rate in a diamond synthesizing process by using low-cost high-energy laser, thereby improving the synthetic rate of the diamonds and effectively solving the problem of high-speed mass preparation of diamonds.

Owner:湖北碳六科技有限公司

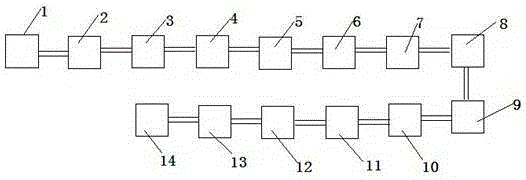

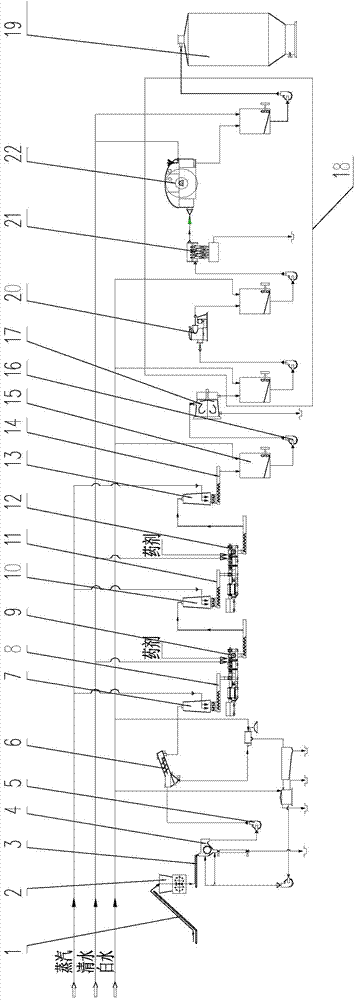

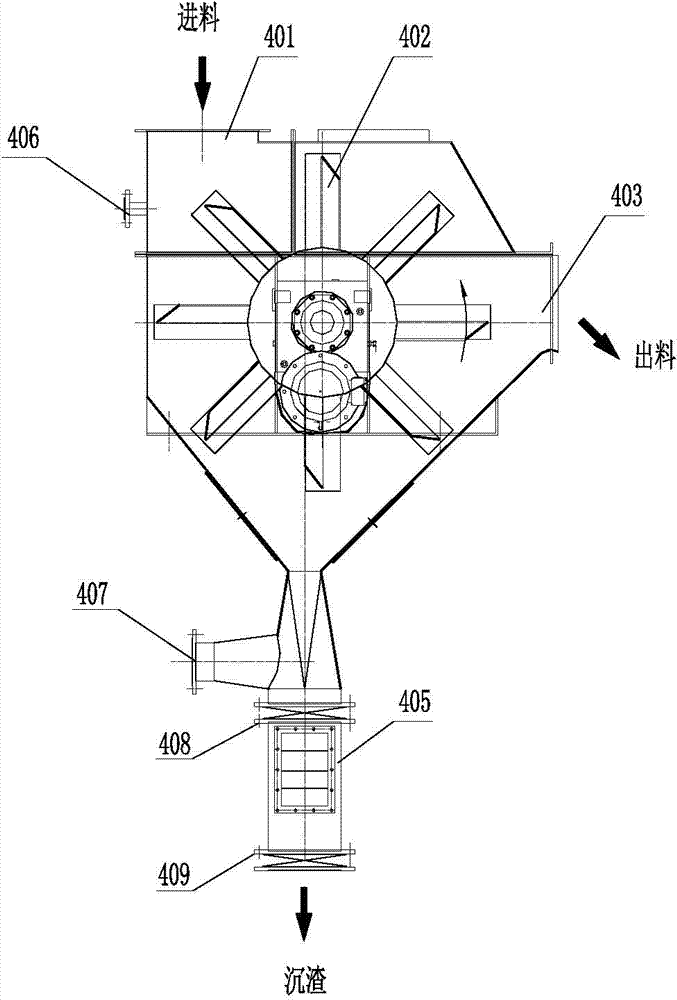

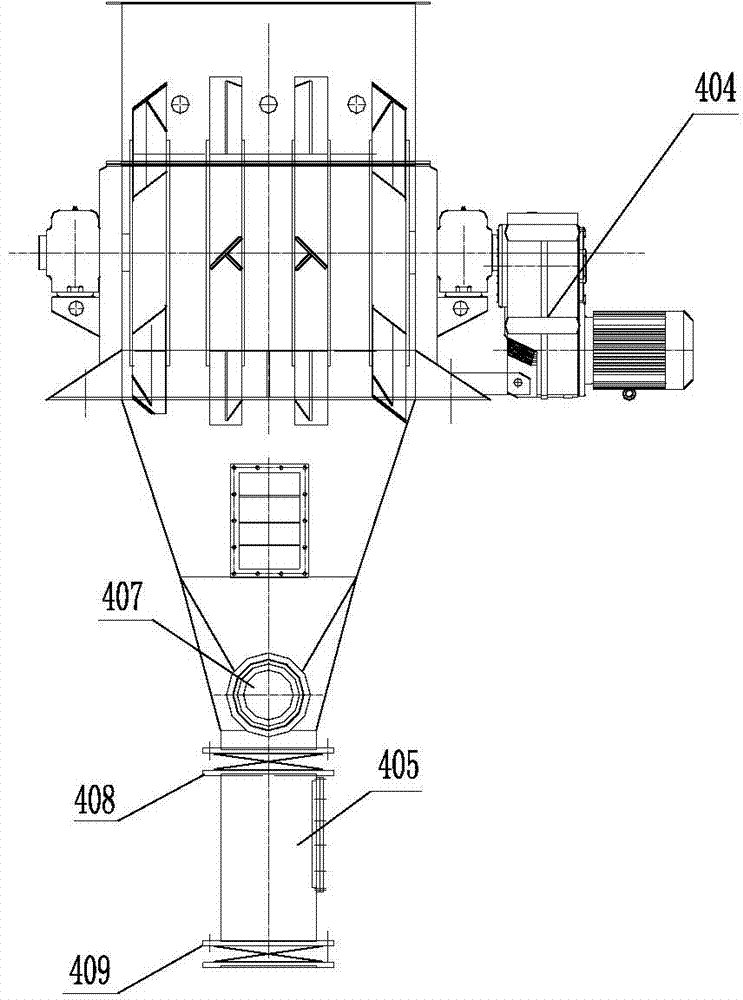

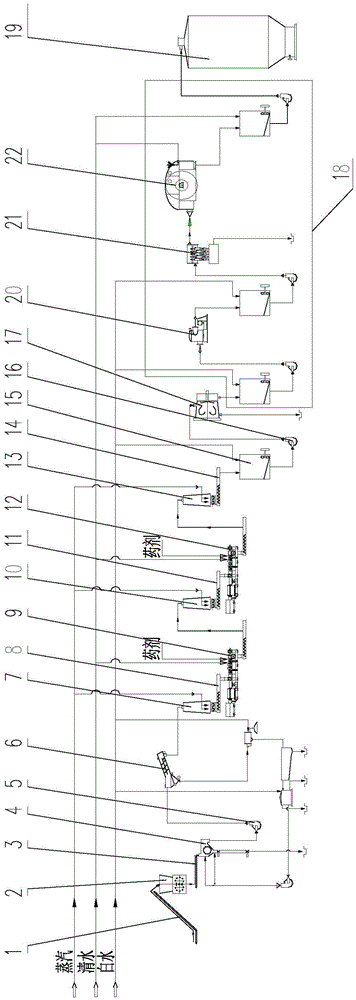

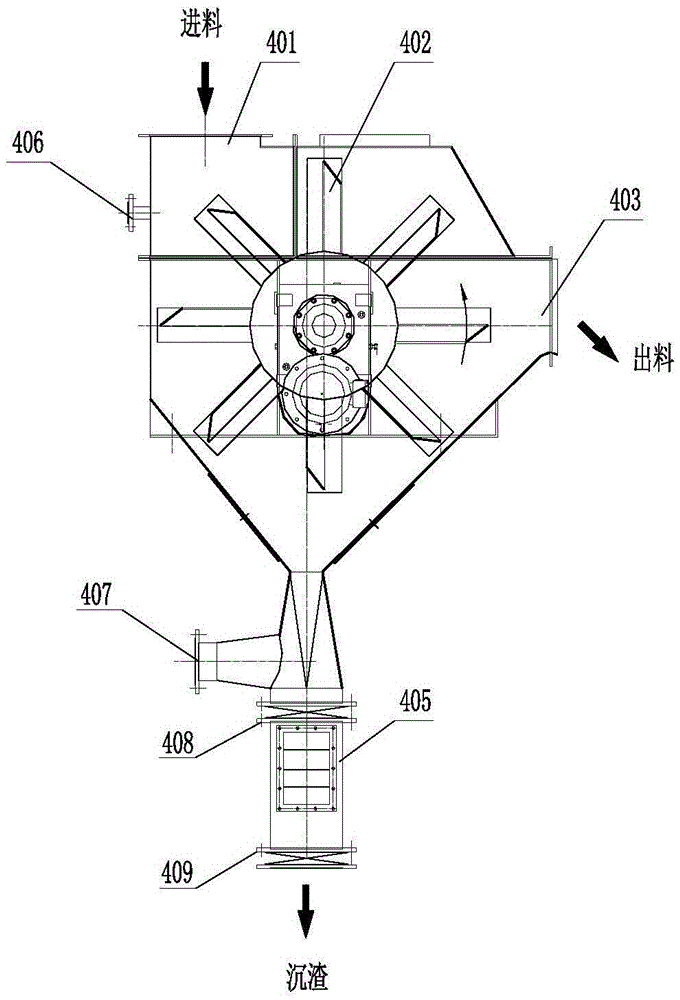

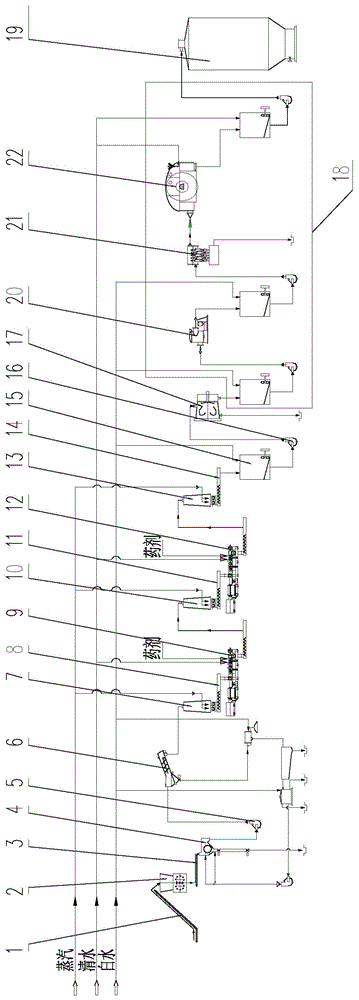

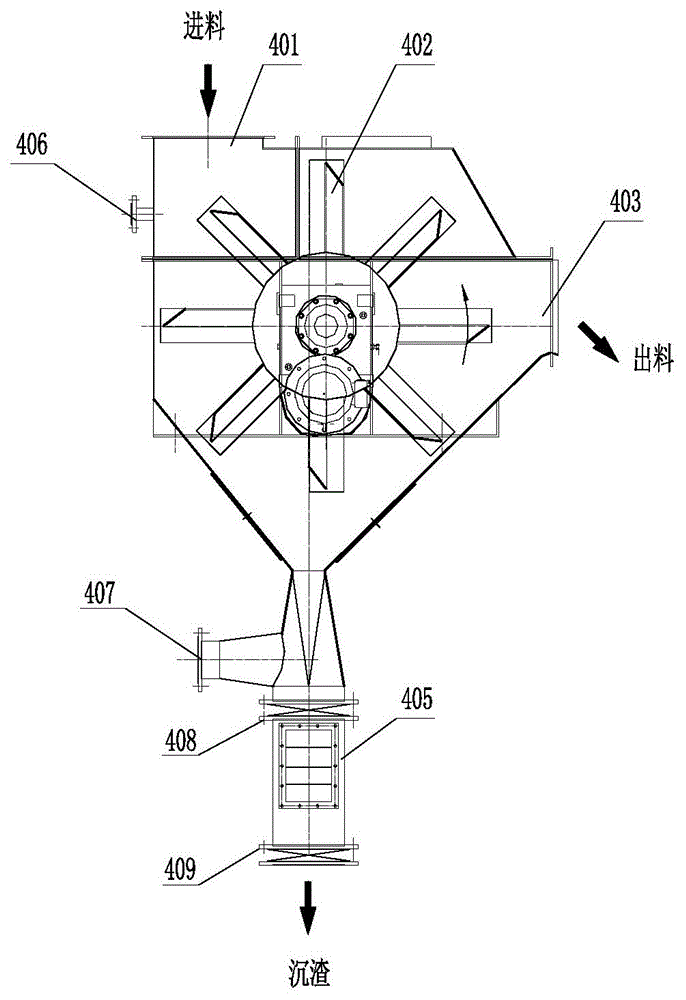

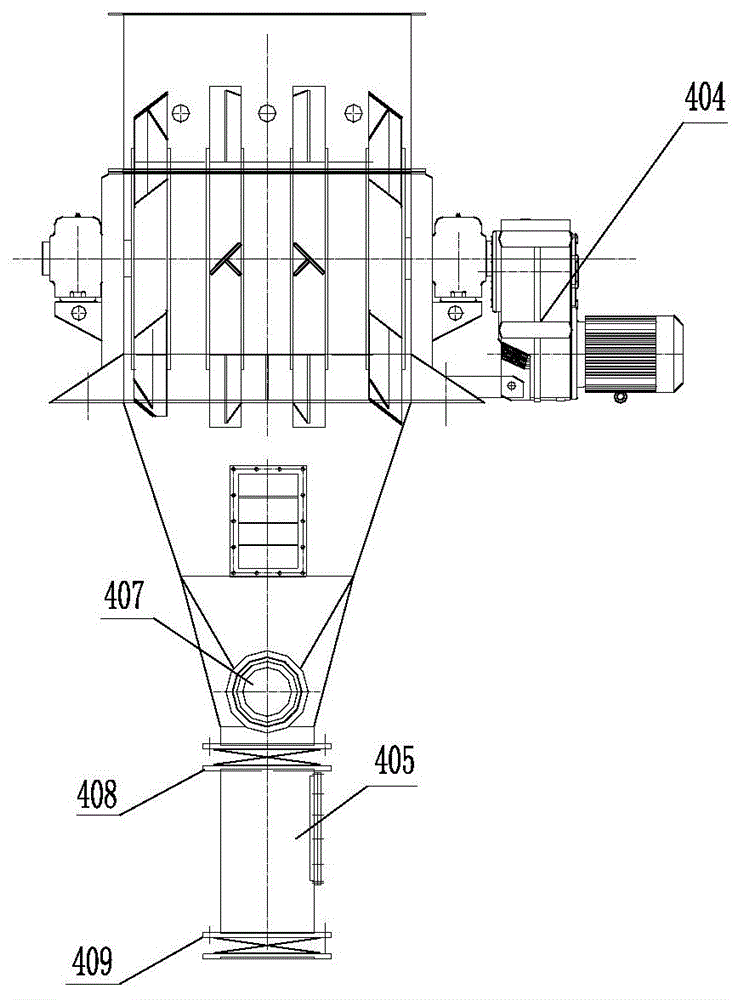

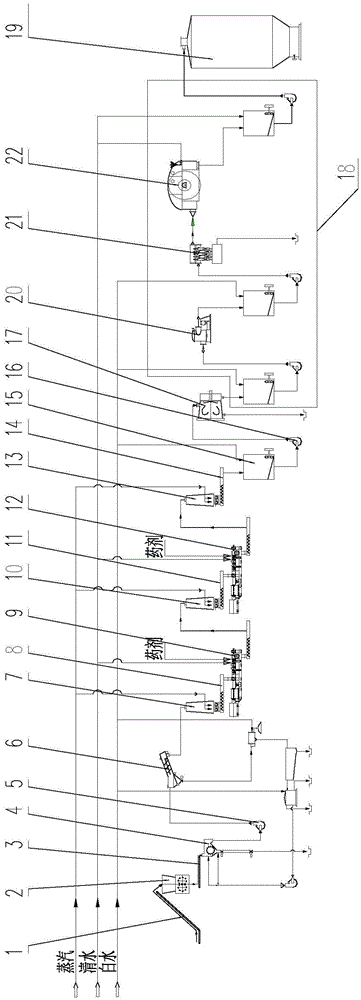

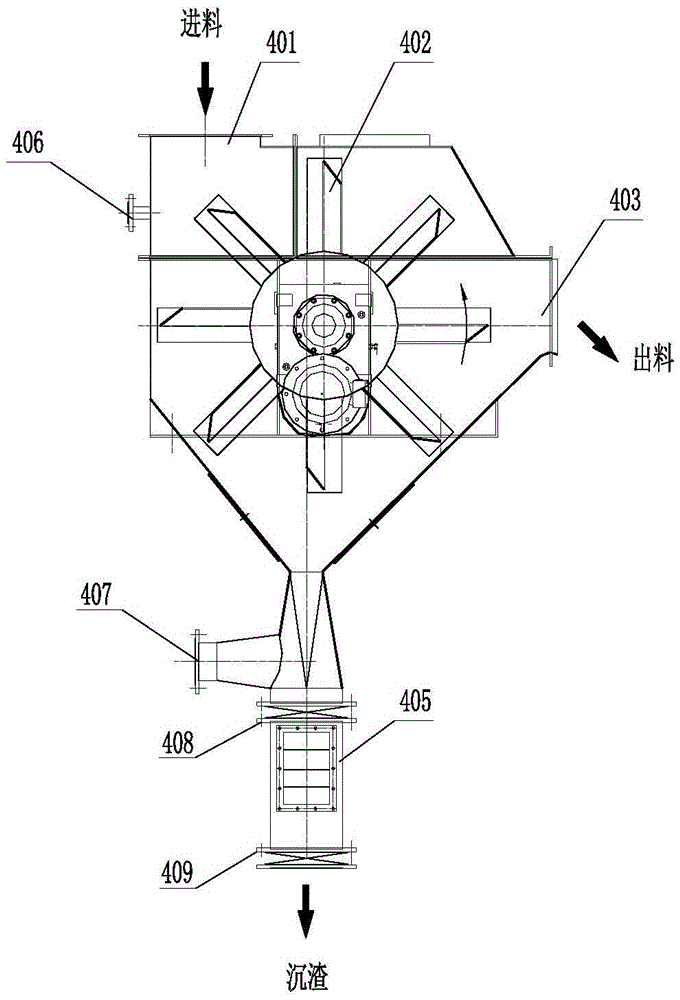

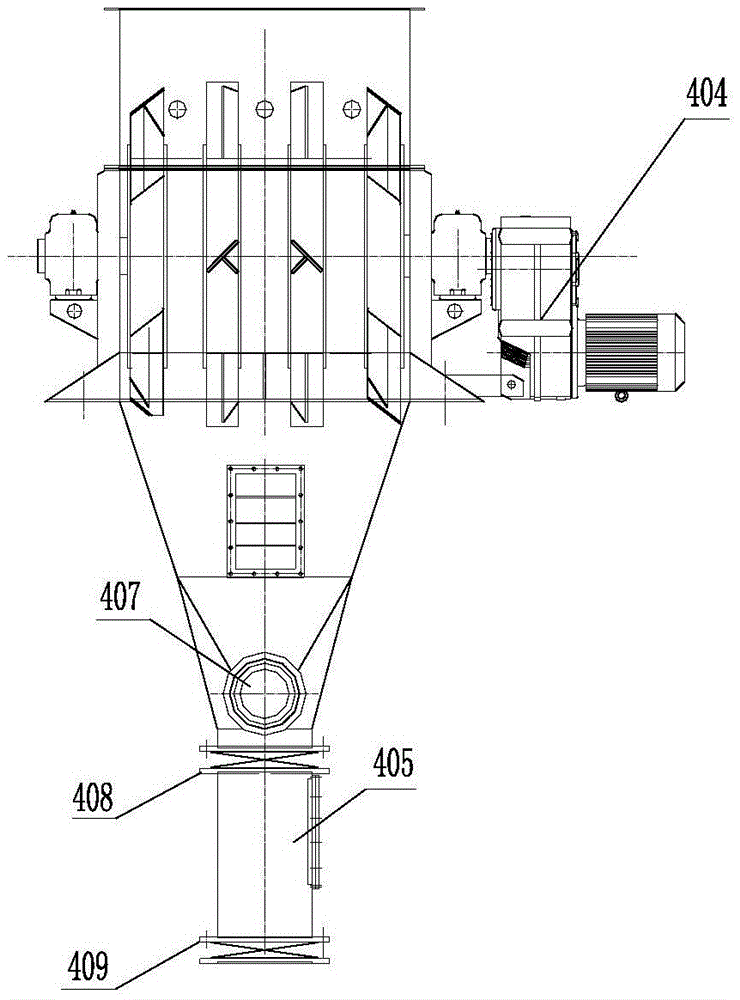

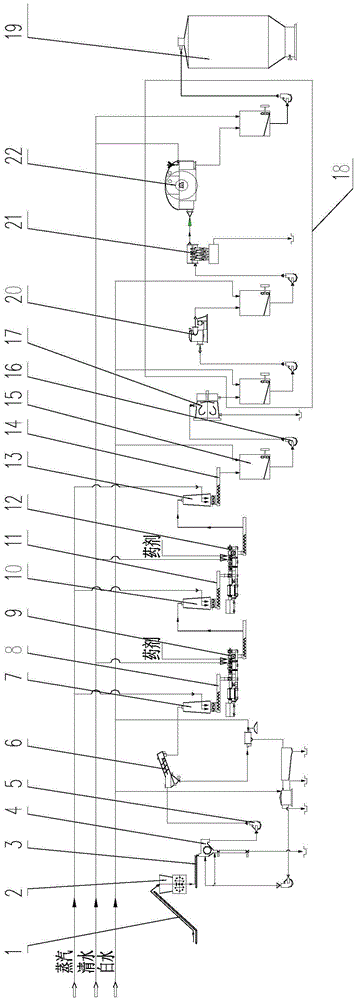

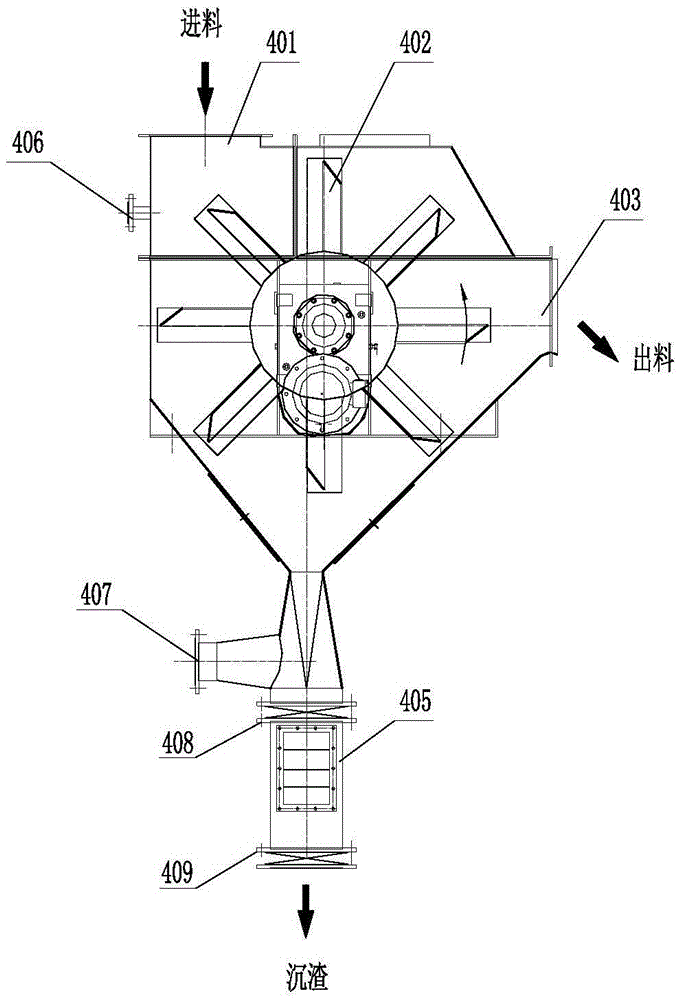

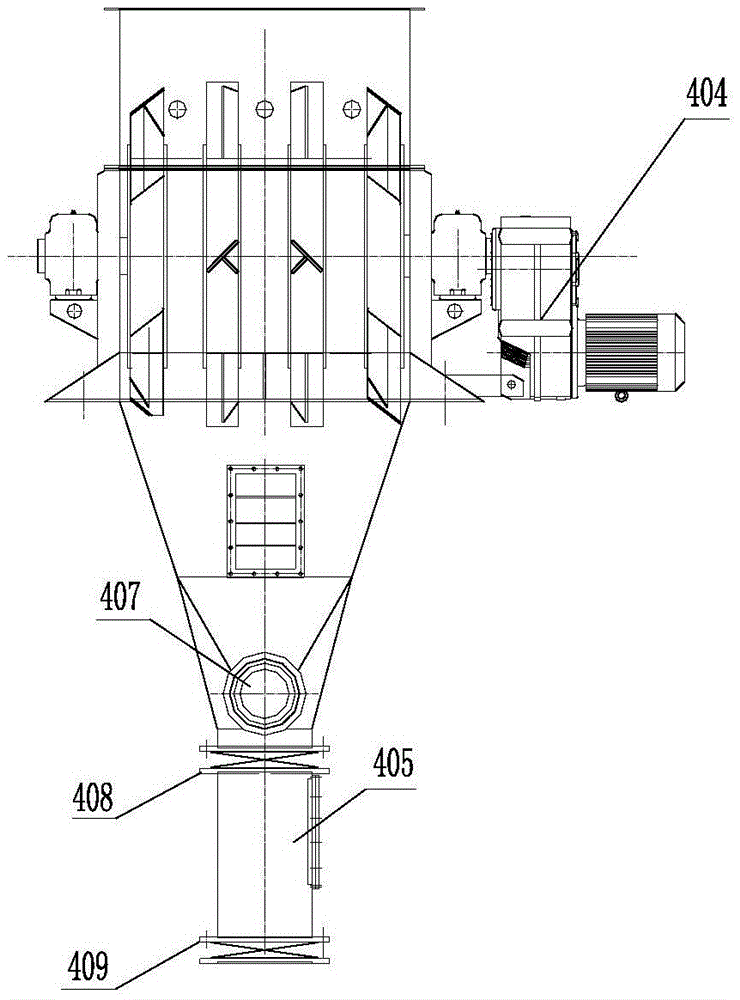

Preparation device and method for recycled paper

InactiveCN106555349AIncrease production capacityAvoid refinementPaper recyclingPulp beating/refining methodsHigh concentrationPulp and paper industry

The invention discloses a preparation device for recycled paper. The preparation device is characterized in that a pulper (1) sequentially communicates with an impurity separator (2), a high-concentration residue remover (3), a fiber separator (4), an outward-flow type pressure slotted screen (5), a low-concentration sand remover (6), a multi-disc concentrator (7), a pulping machine (8), a high-position regulating box (9), a pre-net screen (10), a headbox (11), a long net surface (12), a squeezer (13) and a drying device (14) through a pipeline.

Owner:GUIZHOU FUTAIKAI PAPER IND CO LTD

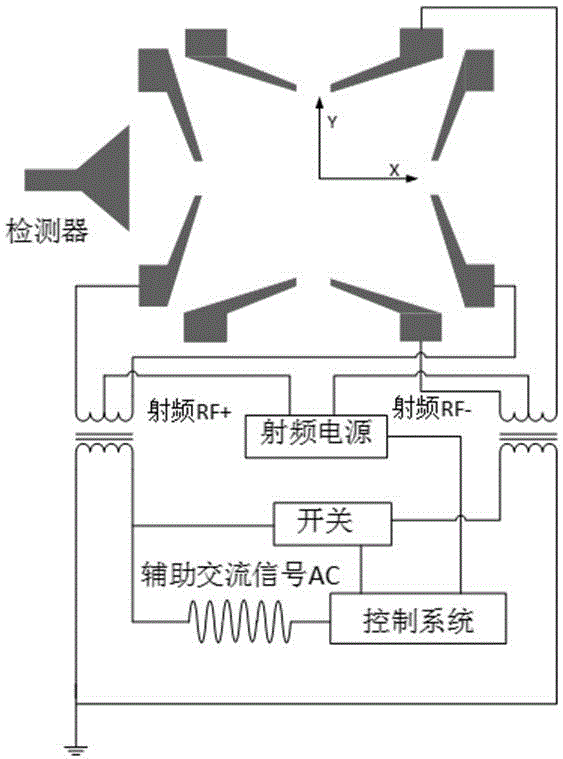

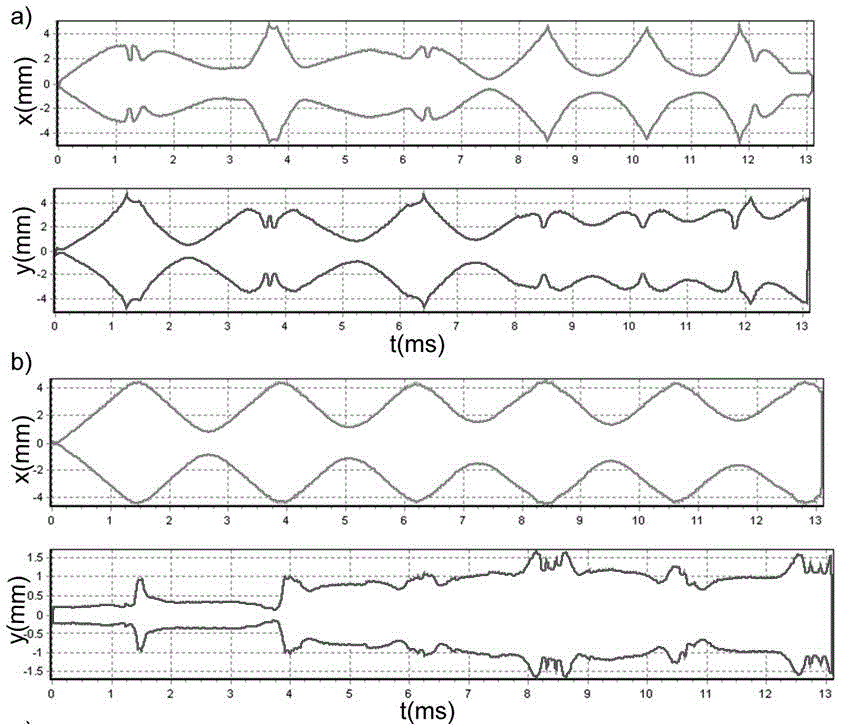

Method of exciting ions in linear ion well

The invention, which belongs to the technical field of quality analysis instruments, particularly relates to a method of exciting ions in a linear ion well. In the linear ion well, in an ion collision induction and dissociation phase, auxiliary exciting signals are applied to a radial X direction and a radial Y direction at the same time, kinetic energy of the ions in the two directions is improved, collision with a central gas is further carried out to make dissociation happen, the kinetic energy is converted into internal energy, and thus tandem mass spectrometry analysis is realized. The method of the invention has the advantages that kinetic energy of the ions in both the X direction and the Y direction can be enhanced; compared with a traditional dissociation method in which ions are mainly excited in one direction, more kinetic energy is converted into internal energy, and thereby improving the dissociation efficiency, narrowing a reaction time, and improving low mass cutoff effects in the ion well.

Owner:FUDAN UNIV

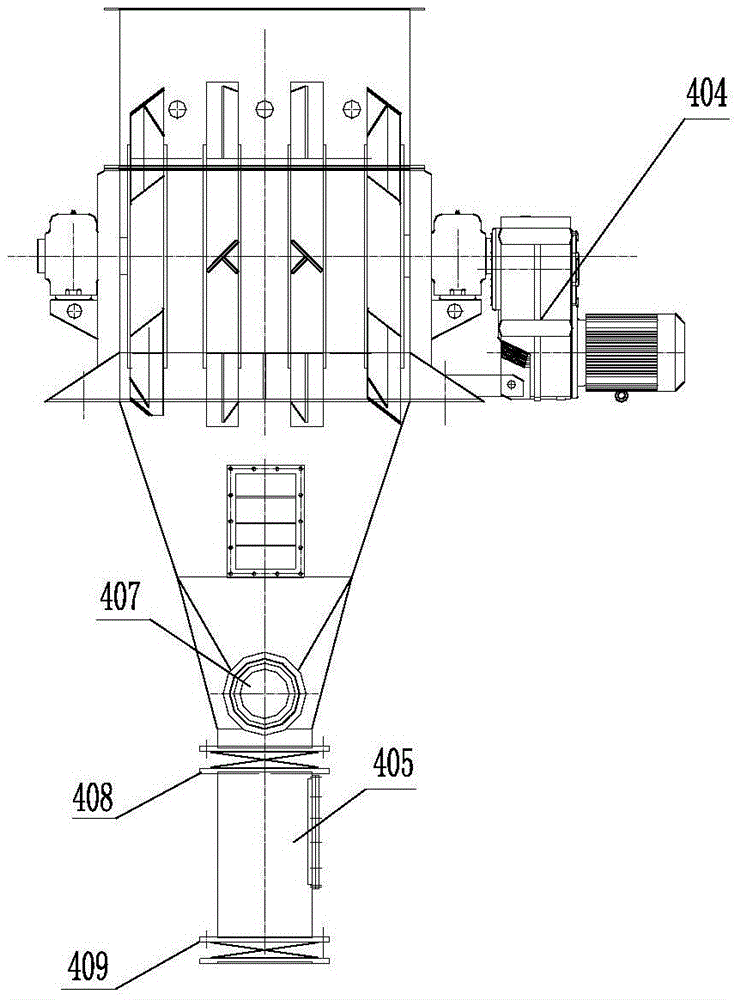

Wet-strength waste paper recycling chemical mechanical pulping system

ActiveCN104120613AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentFiber

The invention discloses a wet-strength waste paper recycling chemical mechanical pulping system. In the material process running direction, the system comprises first conveying equipment, a crusher, second conveying equipment, a tumbler-type washing machine, an oblique spiral dehydrator, a steaming bin, a third spiral conveyer, a first double-screw impregnator, a first reaction bin, a fourth spiral conveyer, a second double-screw impregnator, a second reaction bin, a fifth spiral conveyer, a latency chest, a pulp pump, a fiber separator, a purification, filtration and concentration device and a pulp storage device. The uniform-discharging-type reaction bins are used for achieving uniform discharging so as to reduce the load fluctuation amplitude; the rotary material-poking-type steaming bin is used for eliminating the bridging phenomenon, sufficiently steaming materials so as to soften the materials and reducing chemical consumption; the double-screw impregnators are used for dissociating wet-strength waste paper gradually, achieving high-concentration mixing and homogeneous immersion of chemical agents and pulp and improving the chemical reaction efficiency. The problems that when the wet-strength waste paper is recycled for pulping, the dissociation rate is low and the strength is greatly reduced are solved through the effects of mechanical strength and chemical treatment.

Owner:JIANGSU JINWO MACHINERY

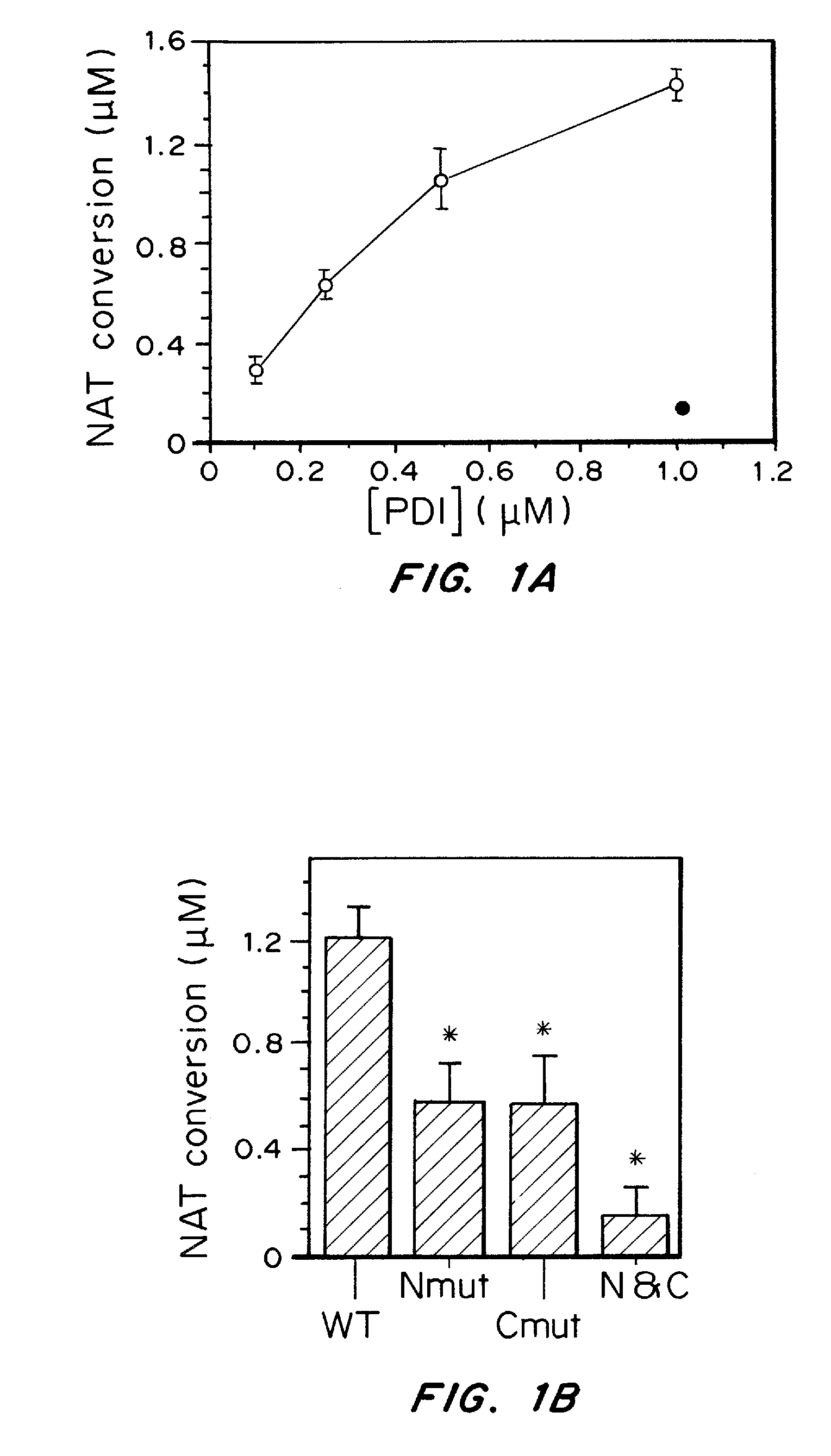

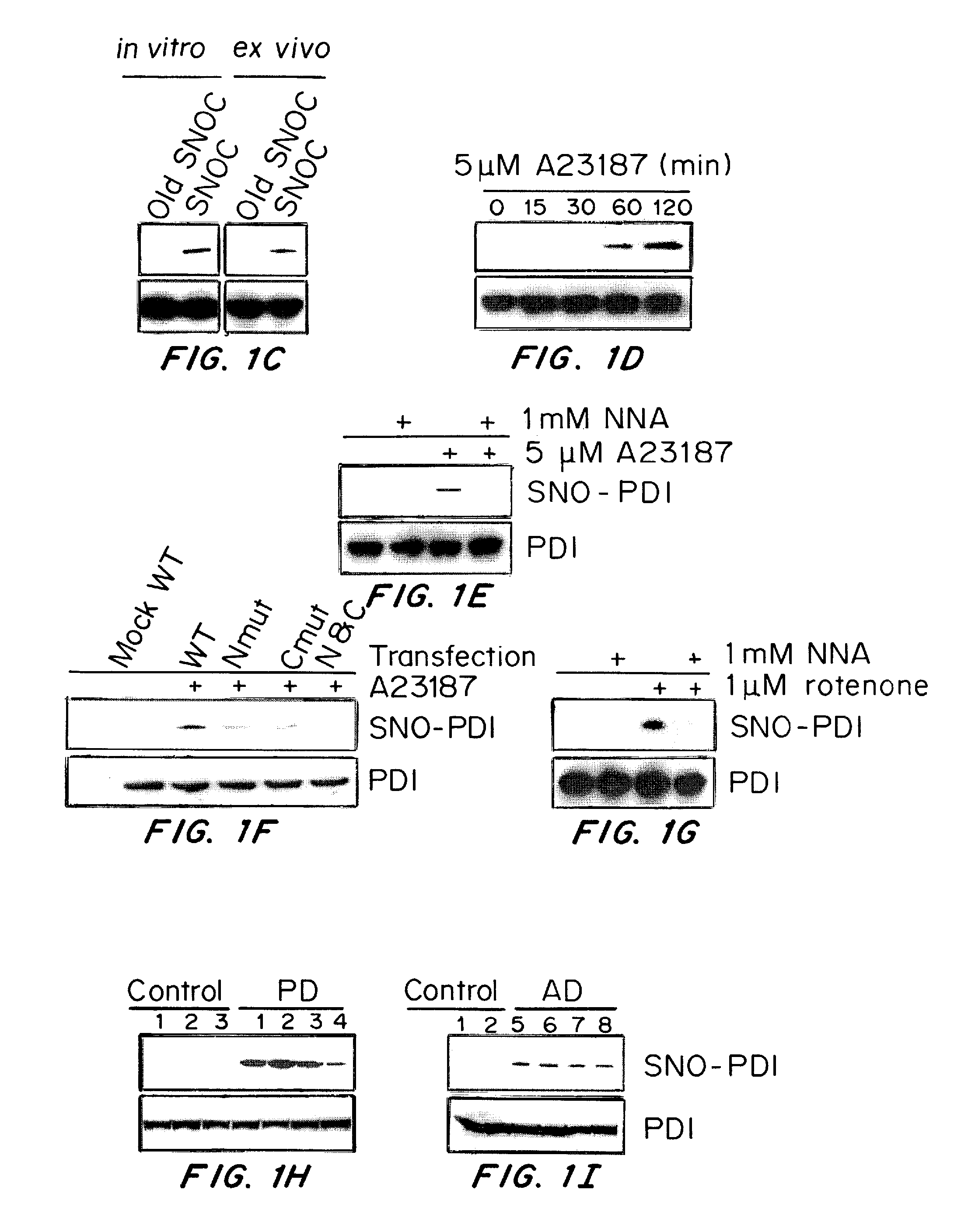

Pathologically-activated therapeutics

InactiveUS20110171291A1Affect activityIncrease dissociation rateNervous disorderLibrary screeningCrystallographyChemical compound

Disclosed are methods and compositions for identifying, producing, and using pathologically-activated targeting compounds. Pathologically-activated compounds are compound that only have an effect, or have a disproportionate effect, on a target molecule when a pathological condition exists.

Owner:SANFORD BURNHAM MEDICAL RES INST

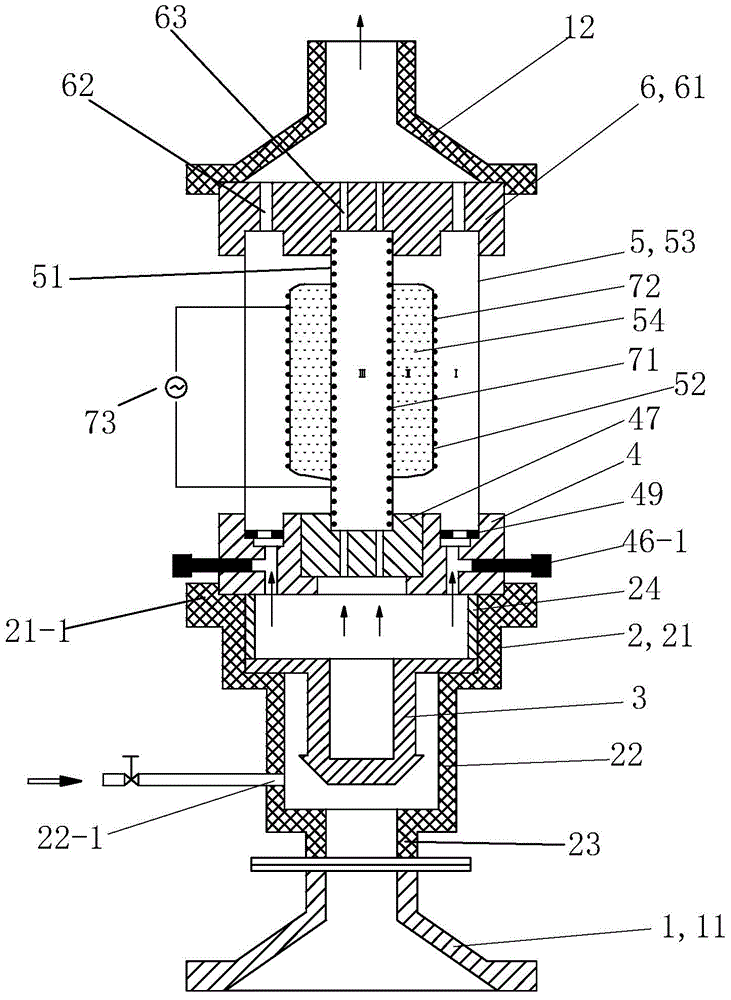

Device and method for waste gas photocatalytic degradation using electrodeless excimer lamp

ActiveCN103182245AEasy to handleWide wavelength rangeDispersed particle separationReaction zonePhotocatalytic degradation

The invention discloses a device and a method for waste gas photocatalytic degradation using an electrodeless excimer lamp. A used reactor comprises a three quartz medium layer, an inner electrode, an outer electrode and a high-voltage power supply, wherein the three-layer quartz medium layer comprises a first quartz tube, a second quartz tube and a third quartz tube, which are coaxial and are sequentially arranged from inside to outside; the inner cavity of the first quartz tube is a zone I reaction zone; a hermetic circular cavity is formed between the second quartz tube and the first quartz tube, and is used as a gas filling zone II; and a zone III reaction zone is formed between the third quartz tube and the second quartz tube. During waste gas photocatalytic degradation, gas in the gas filling zone II is excited to generate excimer UV-light, and then sends radiation towards the zone I reaction zone and the zone III reaction zone; and the waste gas to be degraded all passes through the zone I reaction zone, or all passes through the zone III reaction zone, or split-flows into the zone I reaction zone and the zone III reaction zone, and is then degraded under the action of the excimer UV-light radiation.

Owner:JIANGSU UNIV OF TECH

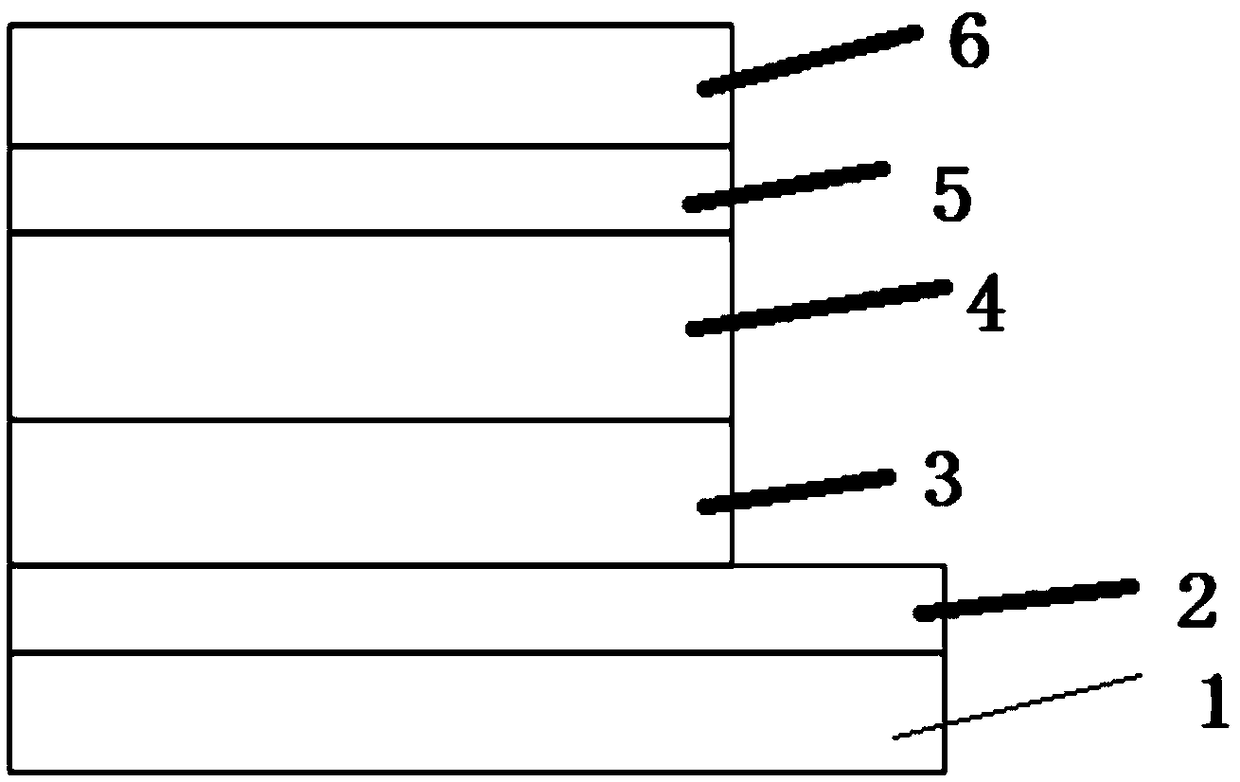

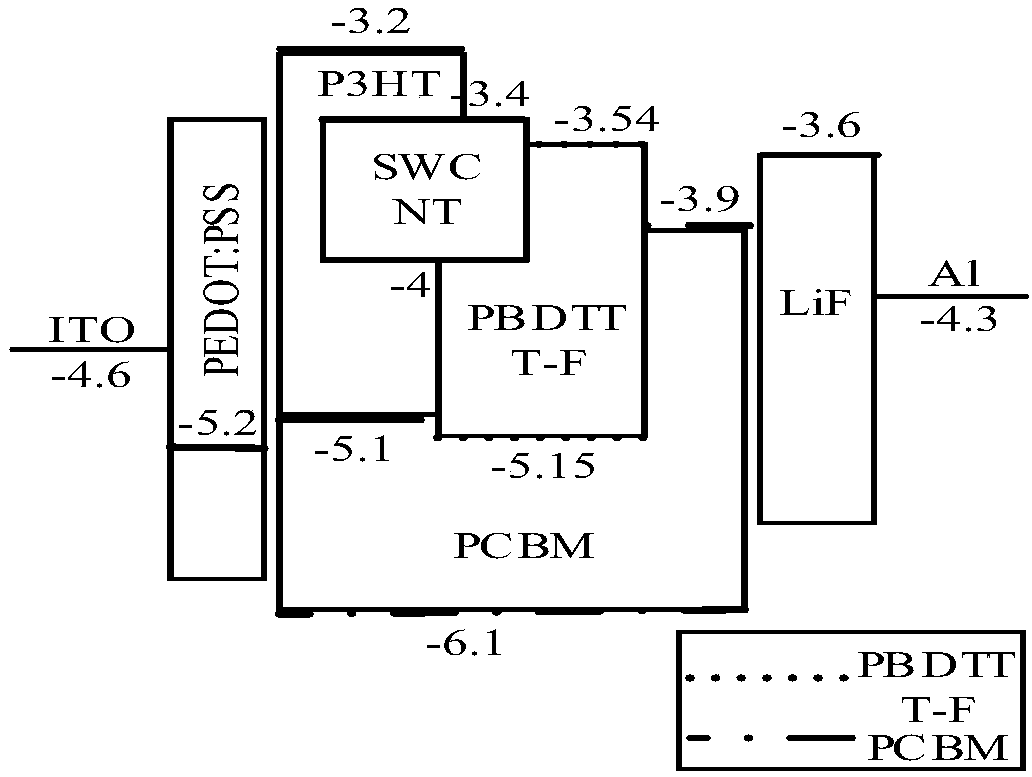

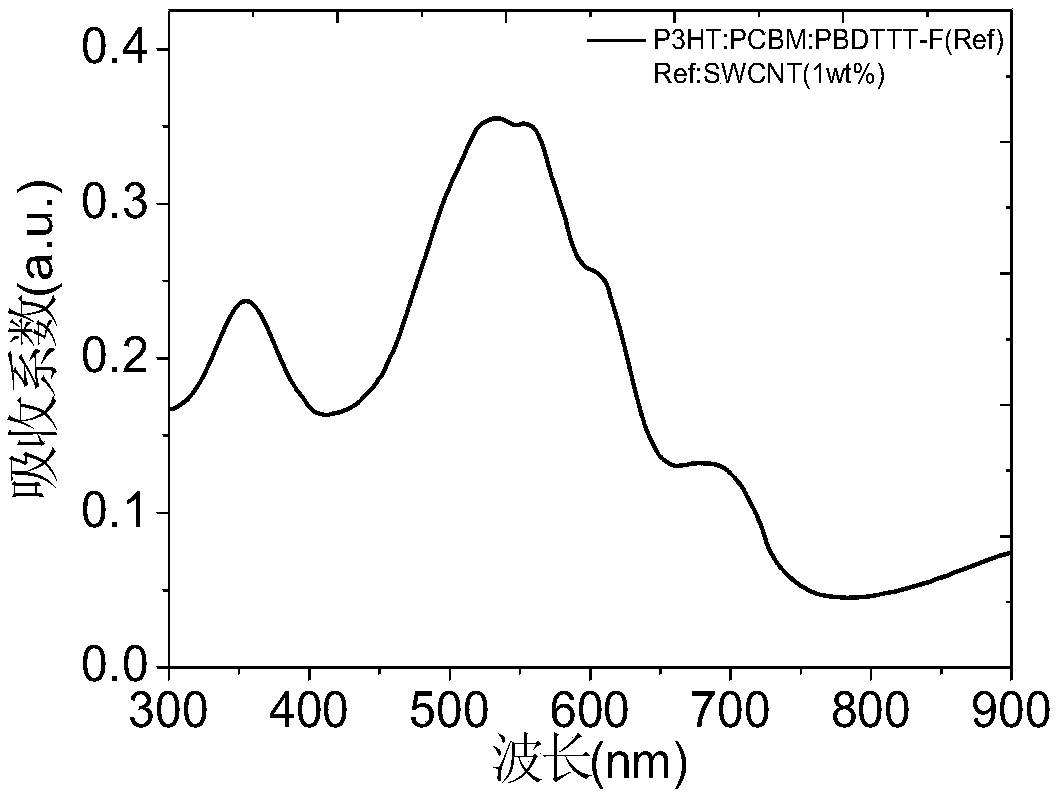

An organic photodetector for a wide spectrum and a preparation method thereof

InactiveCN109065721ABroaden the response rangeImprove mobilityFinal product manufactureSolid-state devicesPhotovoltaic detectorsIndium tin oxide

The invention discloses an organic photodetector for a wide spectrum, comprising a glass substrate, an ITO (indium tin oxide) electrode layer is plated on the glass substrate, and an anode buffer layer, an active layer, a cathode buffer layer and an Al electrode layer are sequentially coated on the surface of the ITO electrode layer from bottom to top. The anode buffer layer and cathode buffer layer can enhance the collection of holes or electrons so as to increase the photocurrent, block electrons or holes to reduce the dark current, improve the specific detection rate of the detector, and avoid the high leakage current caused by SWCNT in the active layer.

Owner:XIAN UNIV OF TECH

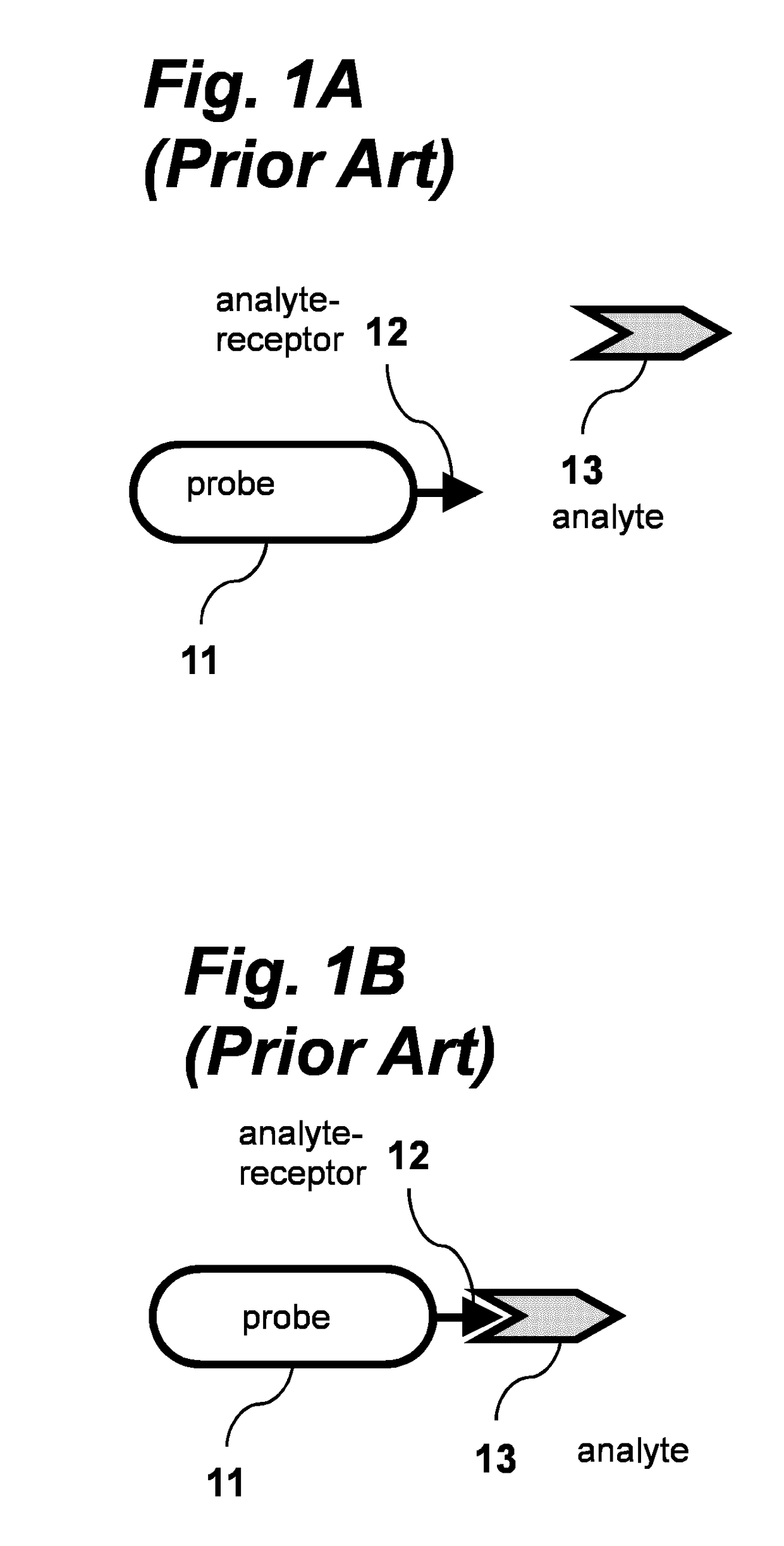

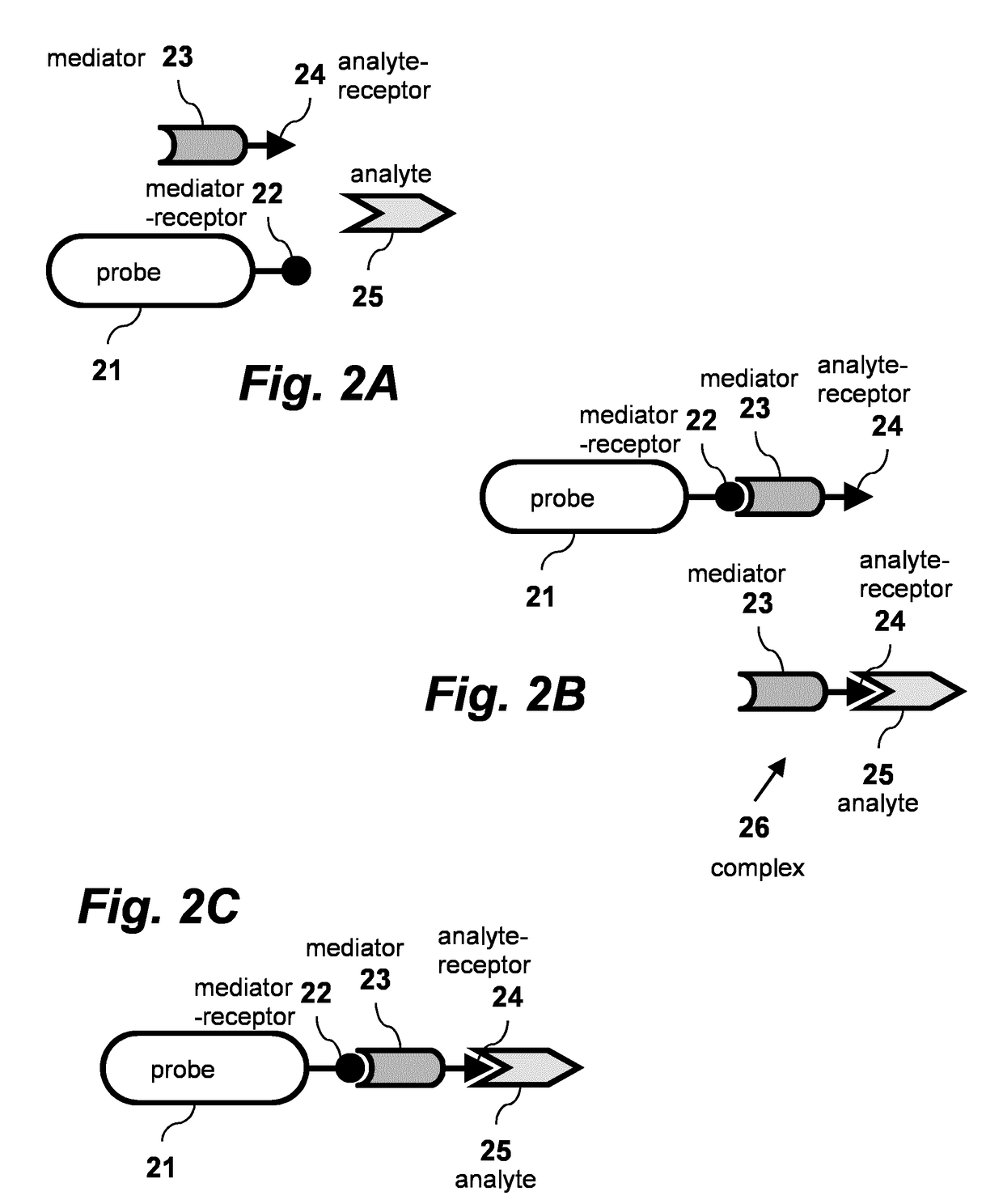

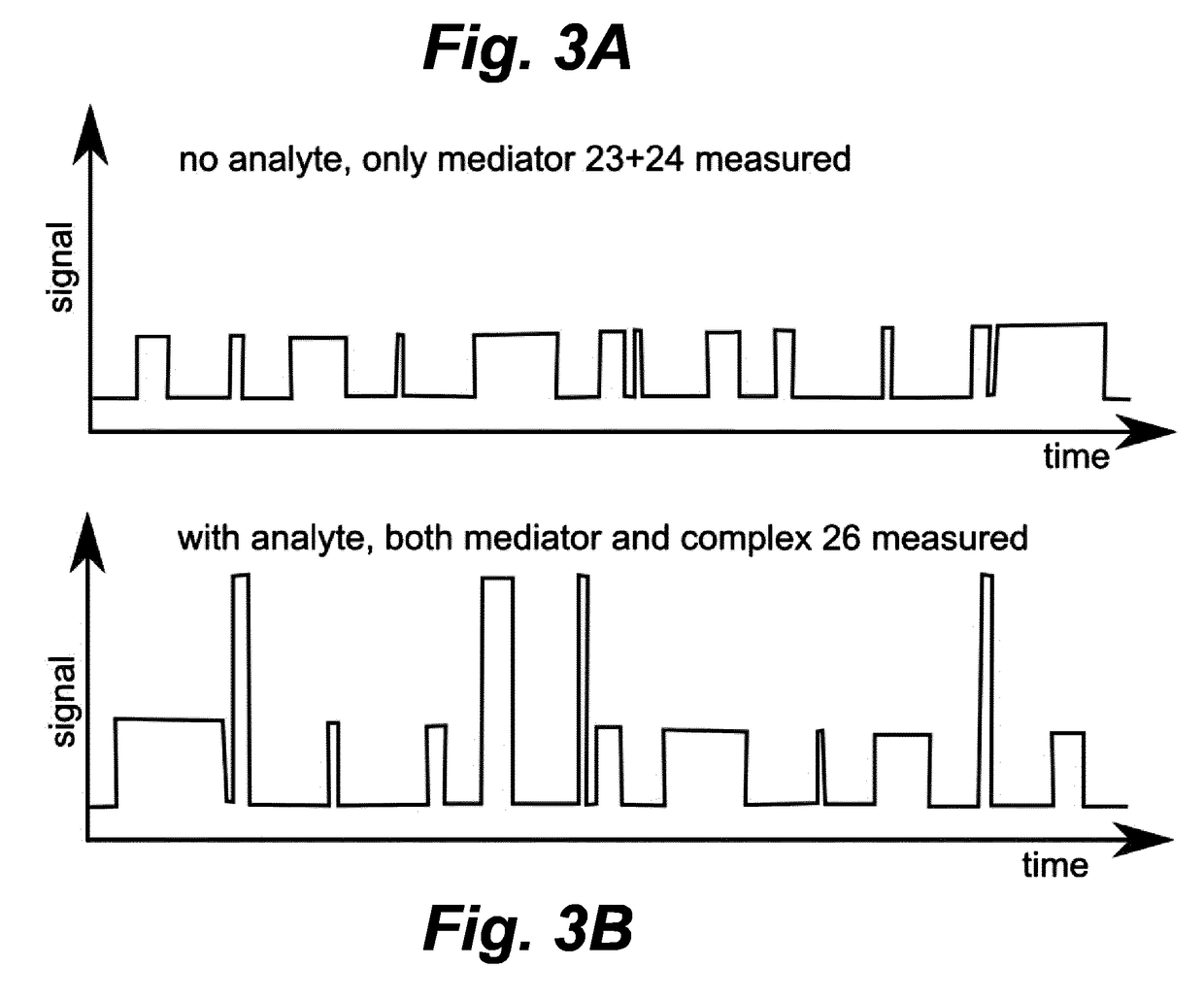

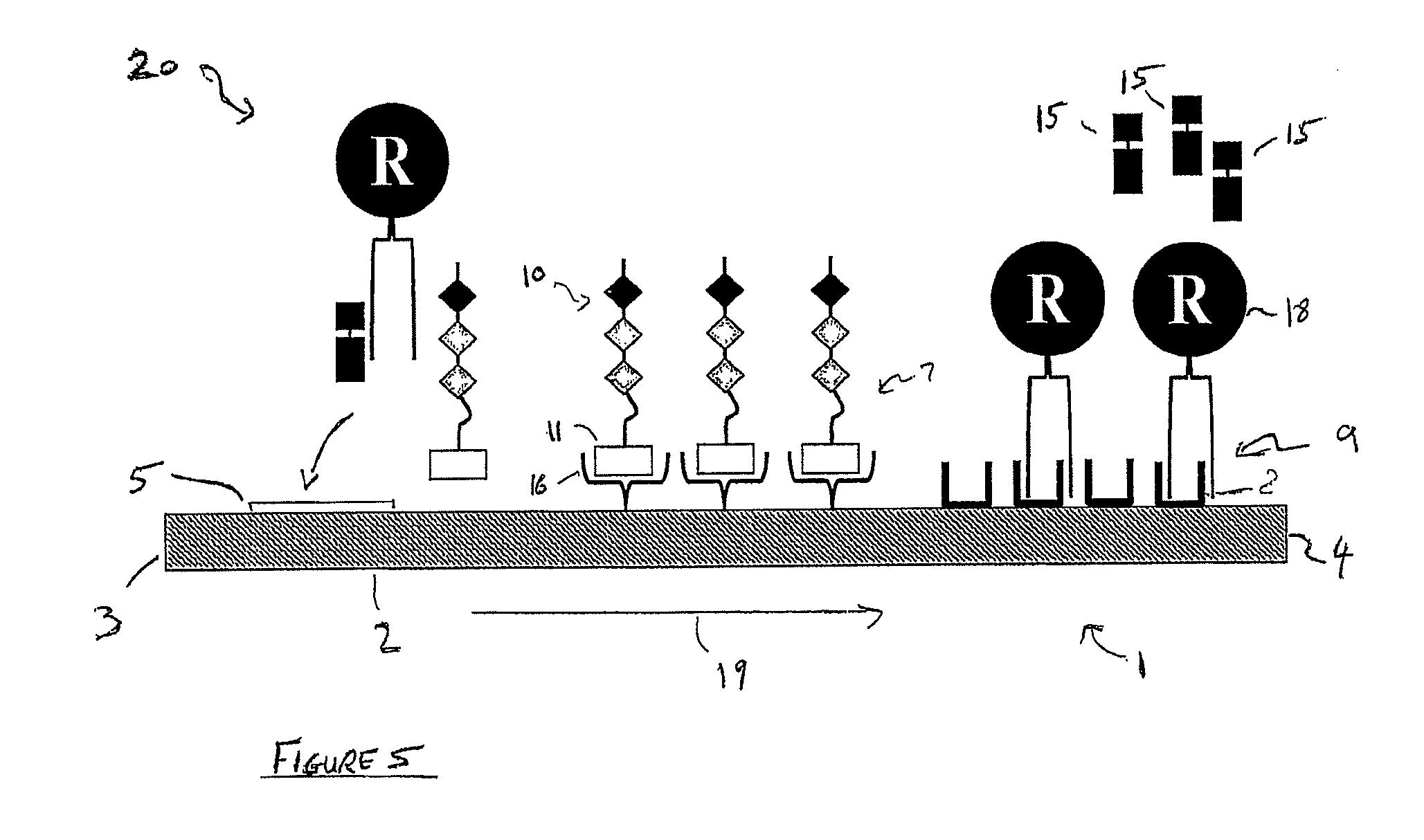

Dynamic switching biosensor

ActiveUS20170315115A1Strong specificityImprove statisticsMicrobiological testing/measurementMaterial analysisAnalyteBiosensor

An analyte [25] in a matrix is sensed using a sensing device having a detection probe [21] conjugated to a mediator-receptor [22] that is not a binder for the analyte. The sensor device is provided with mediators [23] conjugated to analyte-receptors [24], where the mediators are selected to bind to the mediator-receptors, and where the analyte-receptors are selected to bind to the analyte. In some embodiments, the mediators are bound to the detection probe by a tether molecule, or tether molecule fragment, or tether domain. In other embodiments, the mediators are not bound to the detection probe. The presence of the analyte is detected by optically or electrically detecting changes of distance between the mediators and the mediator-receptor, indicative of association and / or dissociation events between mediators and mediator-receptor, the characteristics of which are affected by whether the analyte is bound to the analyte-receptor.

Owner:TECH UNIV EINDHOVEN

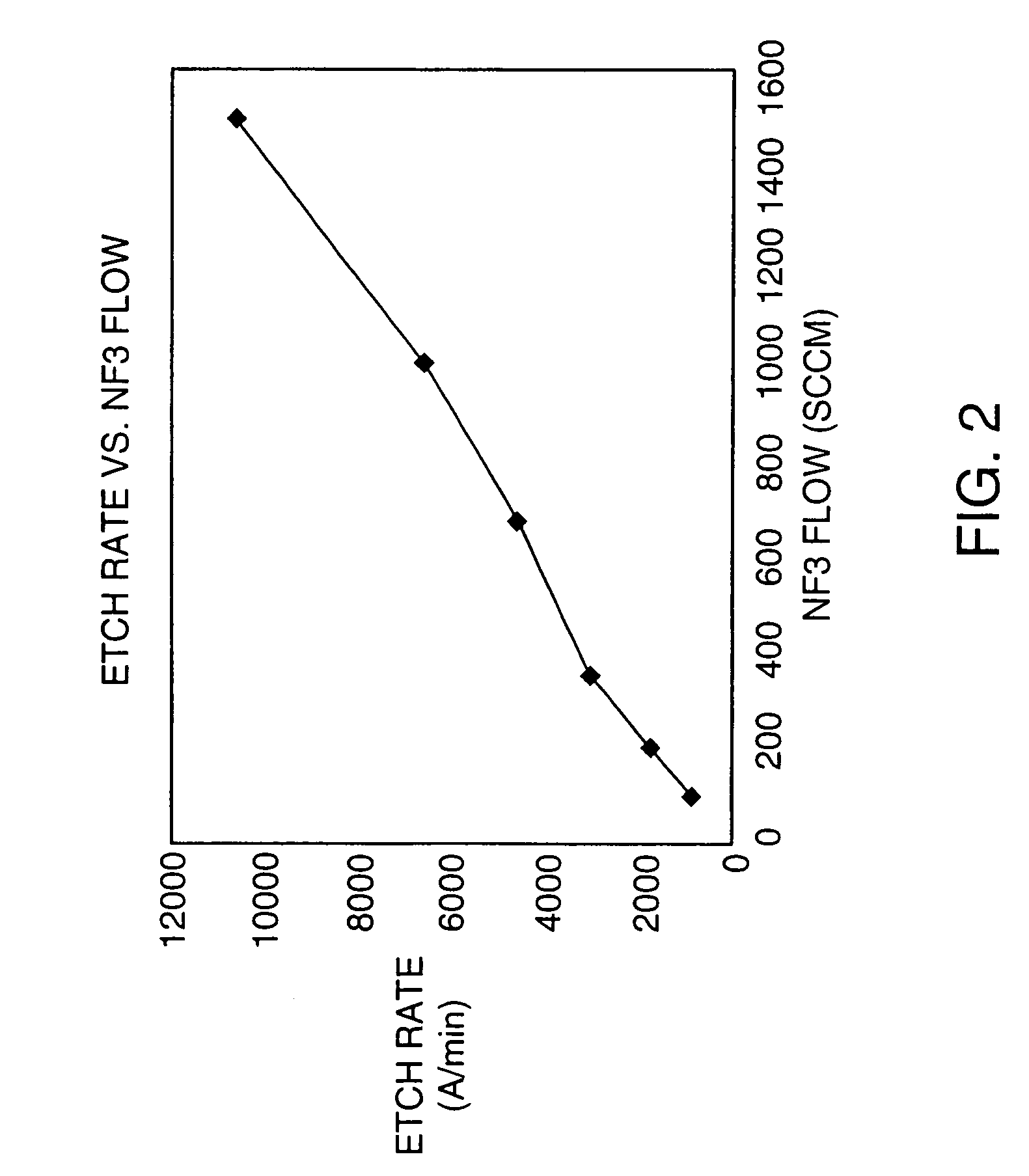

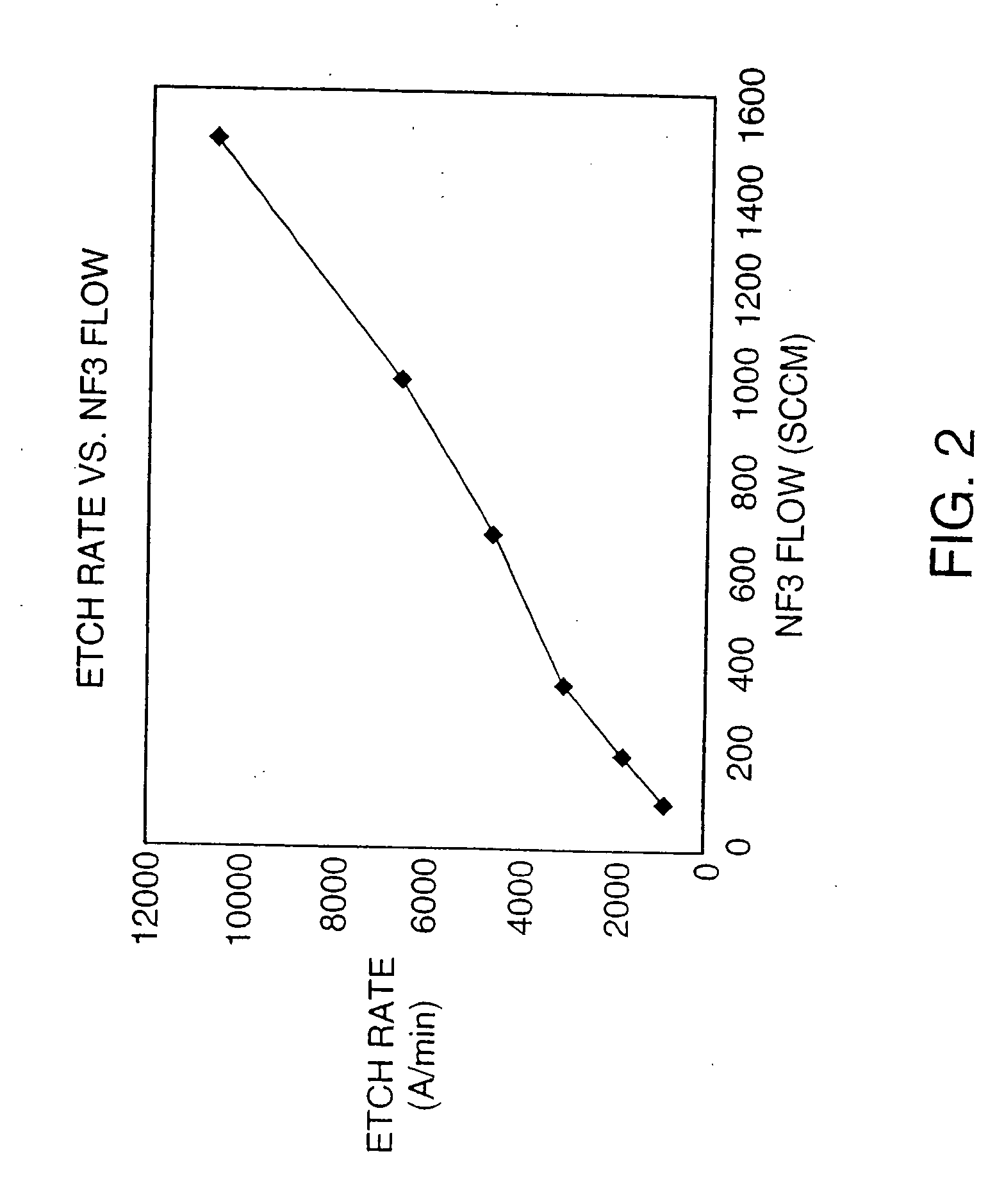

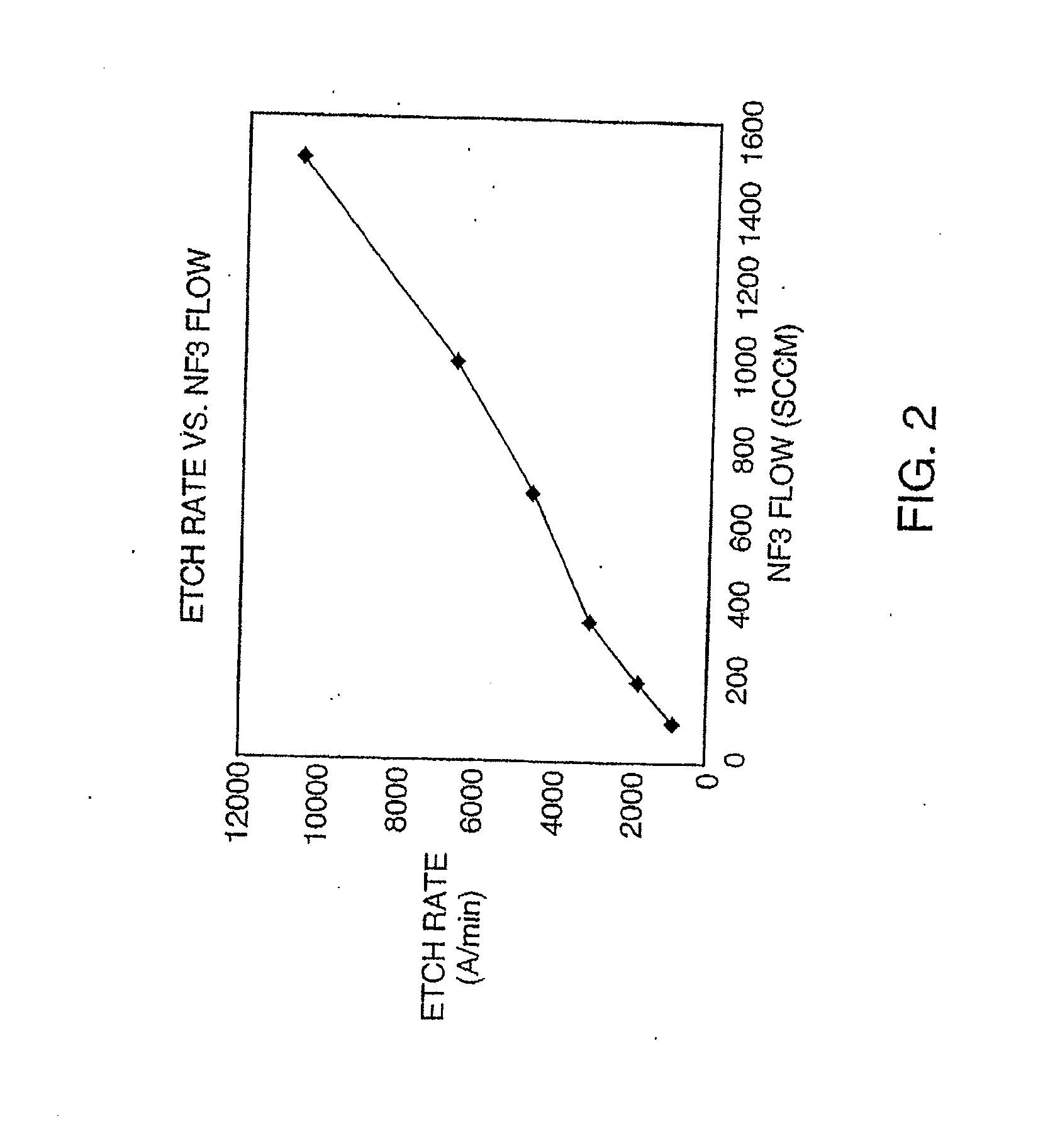

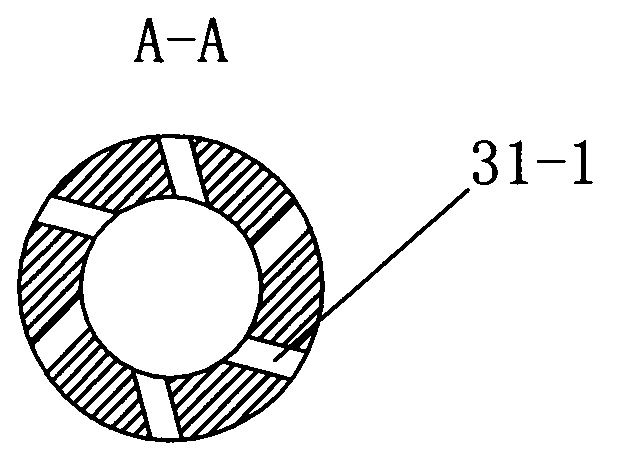

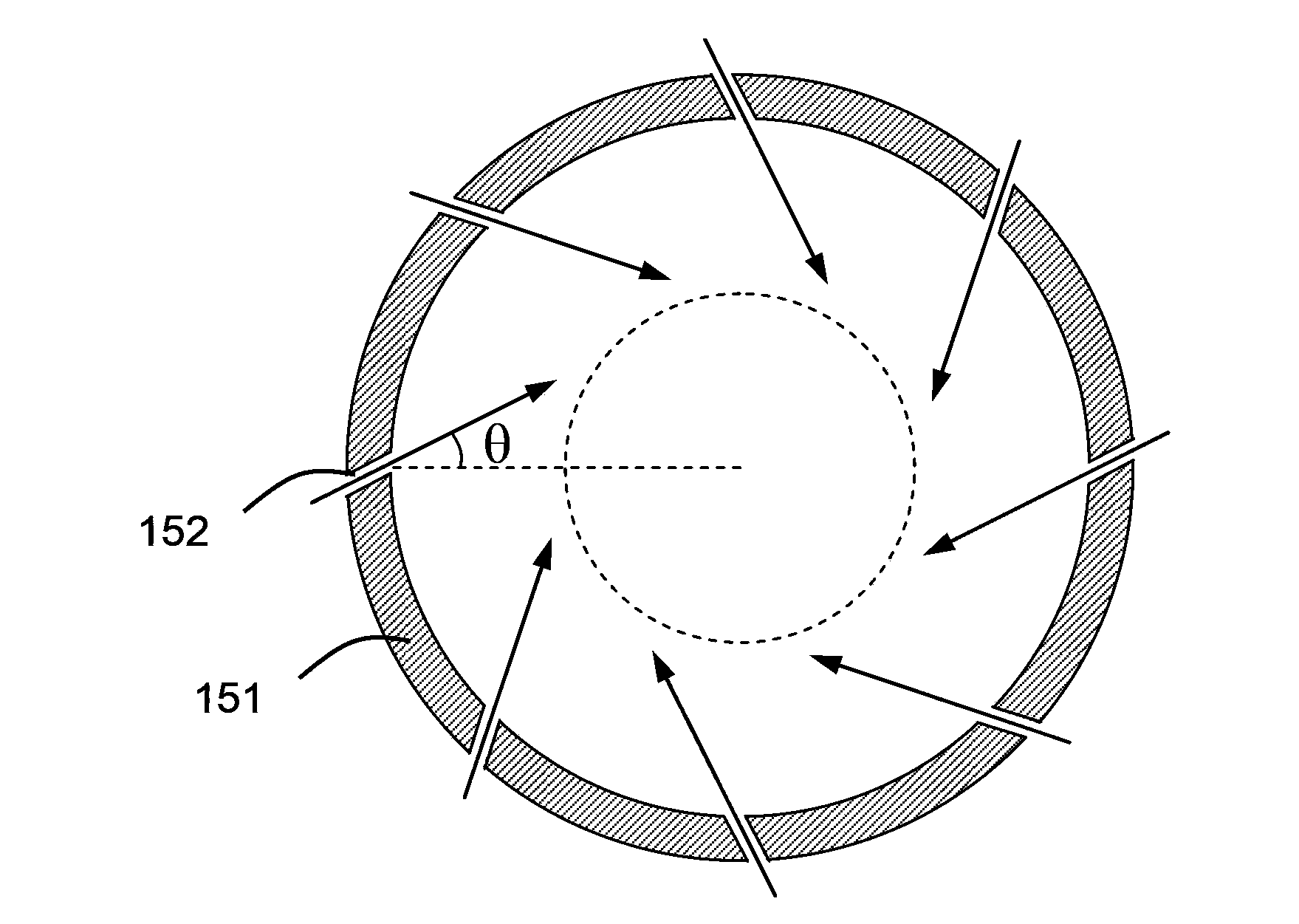

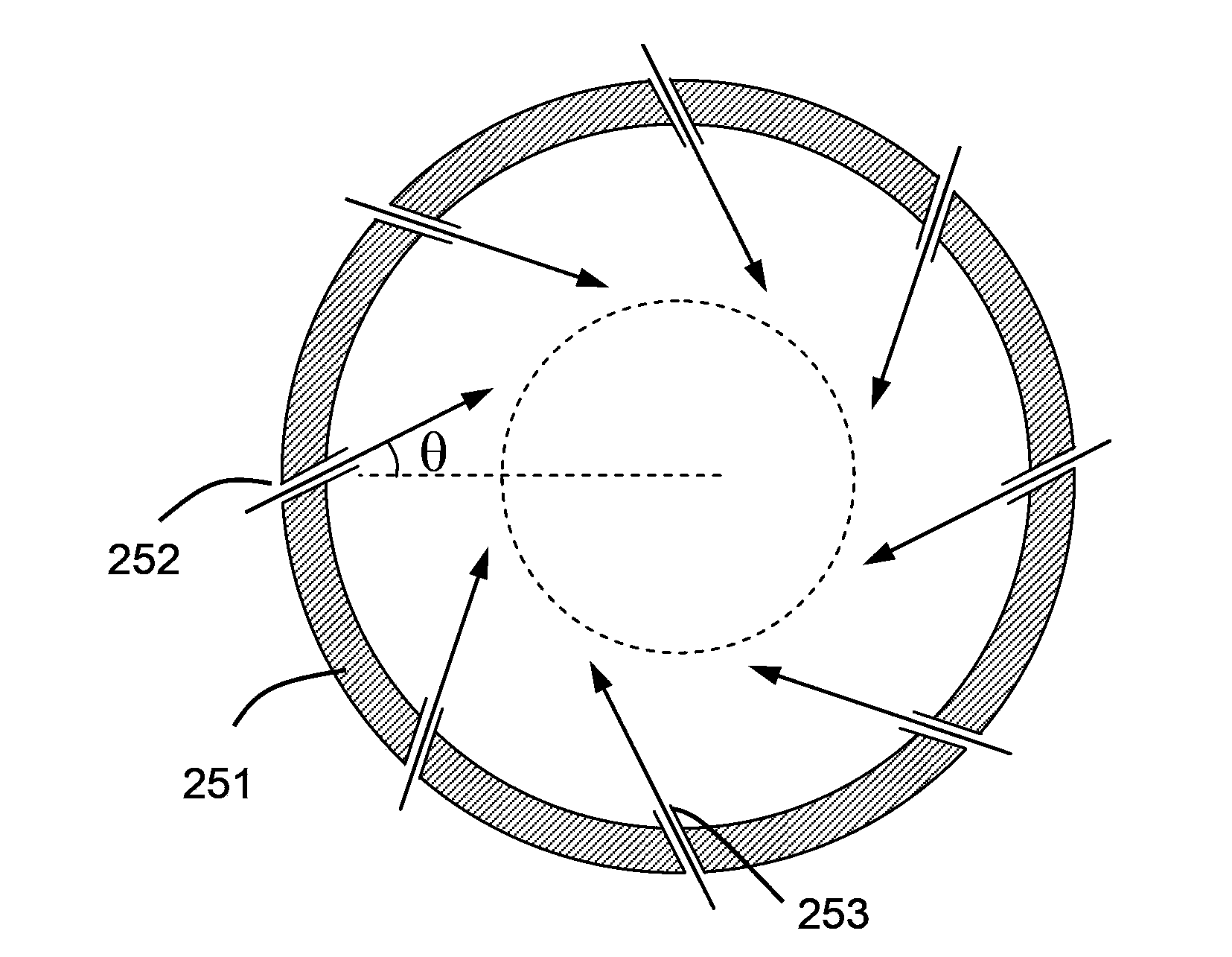

Plasma process chamber and gas injection apparatus for same

ActiveCN103915307ASlow the rate of sinkingSink rate slows downElectric discharge tubesWalking distanceEddy current

The invention discloses a plasma process chamber and a gas injection apparatus for the same. The inner wall of an annular gas injection pipeline is provided with a plurality of gas inlets, an acute angel is formed between a gas output direction and the direction directed towards the circle center of the annular gas injection pipeline by the gas inlet, and it is ensured that gas, after being injected into an reaction chamber, forms eddy current shaped distribution in a dissociation area, so that the gas sinking rate is delayed, the walk distance formed when the gas reaches a substrate is prolonged, and the gas is dissociated as much as possible in the dissociation area. Compared to a conventional gas inlet vertical to the inner wall of the annular gas injection pipeline, the advantages are as follows: the gas sinking rate is slowed, the gas dissociation rate is improved, the reaction gas utilization rate is improved, and at the same time, since the concentration of plasma in the reaction chamber rises, the etching rate is improved.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Pulping system for recycling wet-strength recycled paper

ActiveCN105648817AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentHigh concentration

The invention discloses a chemical mechanical pulping system for recycling wet-strength recycled paper. The system comprises first conveying equipment, a crusher, second conveying equipment, a drum washing machine, an oblique spiral dehydrator, a steaming bin, a third screw conveyer, a first double-screw impregnator, a first reaction bin, a fourth screw conveyer, a second double-screw impregnator, a second reaction bin, a fifth screw conveyor, a latency chest, a stock pump, a fiber separator, a purifying, screening and concentrating device and a pulp storage device in the running direction of the material procedure. The even feeding type reaction bins are utilized for achieving even feeding and reducing the load fluctuation range; the rotary stirring type steaming bin is utilized for eliminating a bridging phenomenon, materials are fully steamed and softened, and chemical consumption is reduced. The double-screw impregnators are utilized for gradually dissociating the wet-strength recycled paper, high-concentration mixing and homogenizing impregnation of a chemical additive and pulp are achieved, and the chemical reaction efficiency is improved. By means of the function of mechanical strong force and chemical treatment, the problems that during wet-strength recycled paper recycling, pulping and dissociating rate is low, and the strength is greatly reduced are solved.

Owner:JIANGSU JINWO MACHINERY

Chemical mechanical pulping method for recycling of wet strength waste paper

ActiveCN104099795AReduce consumptionImprove chemical reaction efficiencyPretreatment with water/steamPretreatment with alkaline reacting compoundsChemical treatmentProcess engineering

The invention discloses a chemical mechanical pulping method for recycling of wet strength waste paper. The method comprises a material preparation section, a steaming section, a first squeezing dipping chemical mechanical treatment section, a second squeezing dipping chemical mechanical treatment section, a latency and re-defibering section and a purification, screening and concentration section. According to the method, wet strength waste paper fiber dissociation and re-pulping are realized while the original pulp strength is not reduced under the action of mechanical strength and chemical treatment; furthermore, at the two squeezing dipping chemical mechanical treatment sections in series connection, a wet strength agent in the waste paper can be oxidized under the acidic condition firstly, and then hydrolysis is further promoted under the alkaline condition, so that the chemical bonding among molecules of the wet strength agent and between the wet strength agent and pulp fibers are destroyed more effectively, and the fiber dissociation rate and the re-pulping yield are effectively increased. The problems that the wet strength waste paper recycling, pulping and dissociation rate is low and the strength is substantially reduced are solved, and continuous, large-scale, low-water-consumption, low-energy-consumption, pollution-free and environment-friendly pulping can be realized.

Owner:JIANGSU JINWO MACHINERY

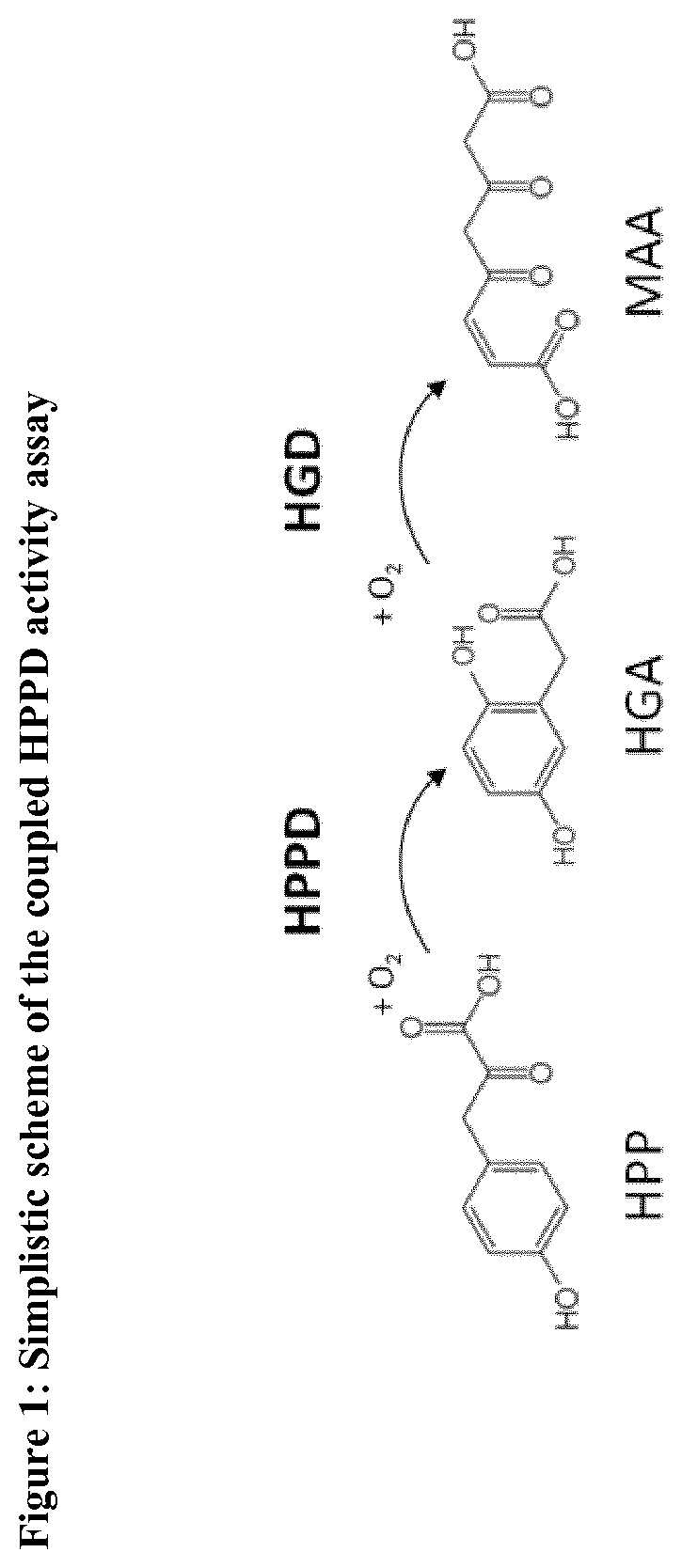

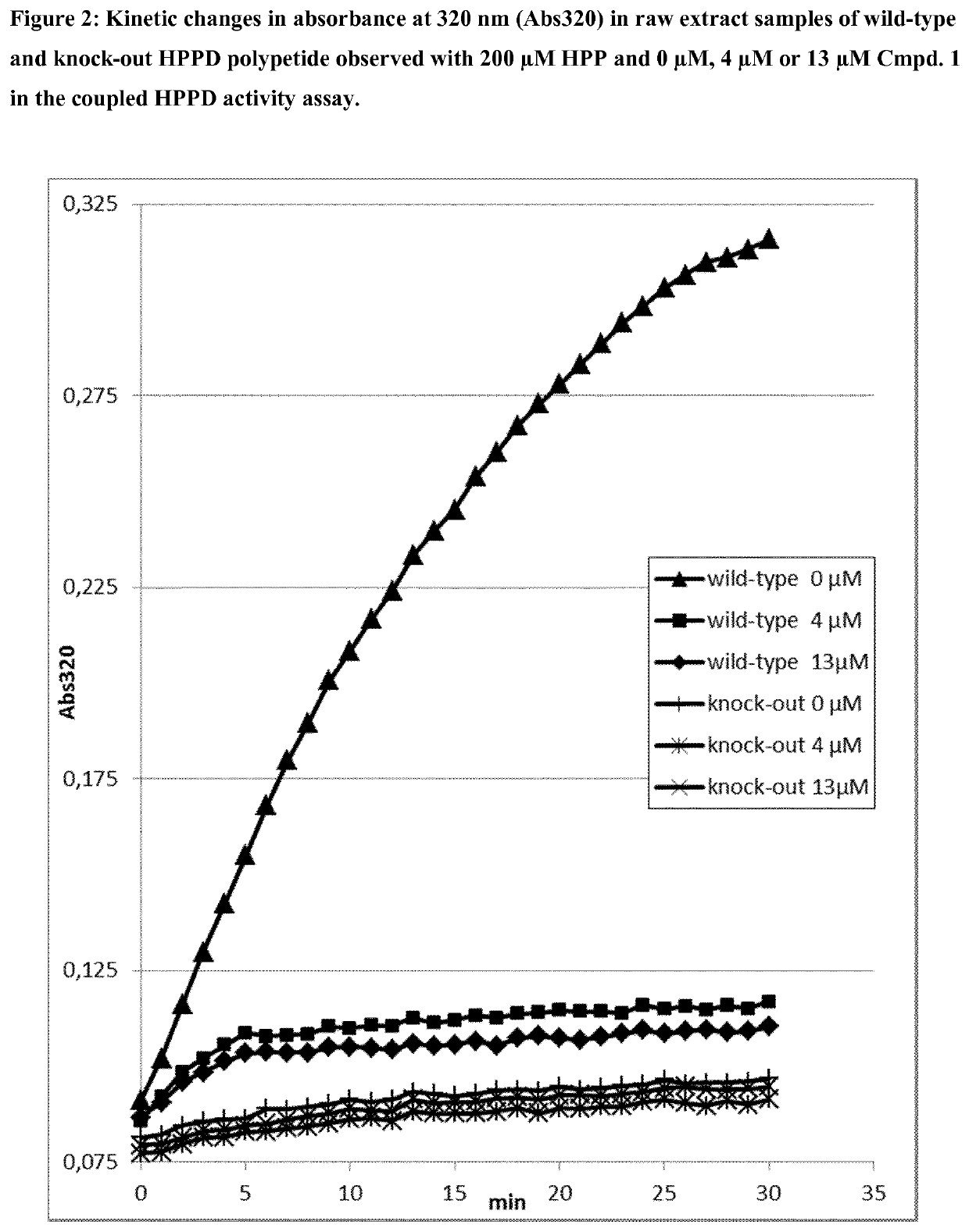

Hppd variants and methods of use

ActiveUS20200239905A1Maximized and broad toleranceIncrease dissociation rateBacteria peptidesOxidoreductasesPolynucleotideAmino acid

In the present invention, HPPD polypeptides and plants containing them showing a full tolerance against one or more HPPD inhibitor herbicides belonging to various chemical classes are described. A set of mutant HPPD polypeptides have been designed which have either no or only a significantly reduced affinity to HPPD inhibitor herbicides and, at the same time, the rate of dissociation of the HPPD inhibitors of the mutant HPPD polypeptide is increased to such an extent that the HPPD inhibitors no longer act as slow-binding or slow, tight-binding inhibitors but, instead of this, have become fully reversible inhibitors. In particular, isolated polynucleotides encoding mutant HPPD polypeptides conferring tolerance to HPPD inhibitor herbicides belonging to various chemical classes are provided. Additionally, amino acid sequences corresponding to the polynucleotides are encompassed.

Owner:BASF AGRICULTURAL SOLUTIONS SEED LLC

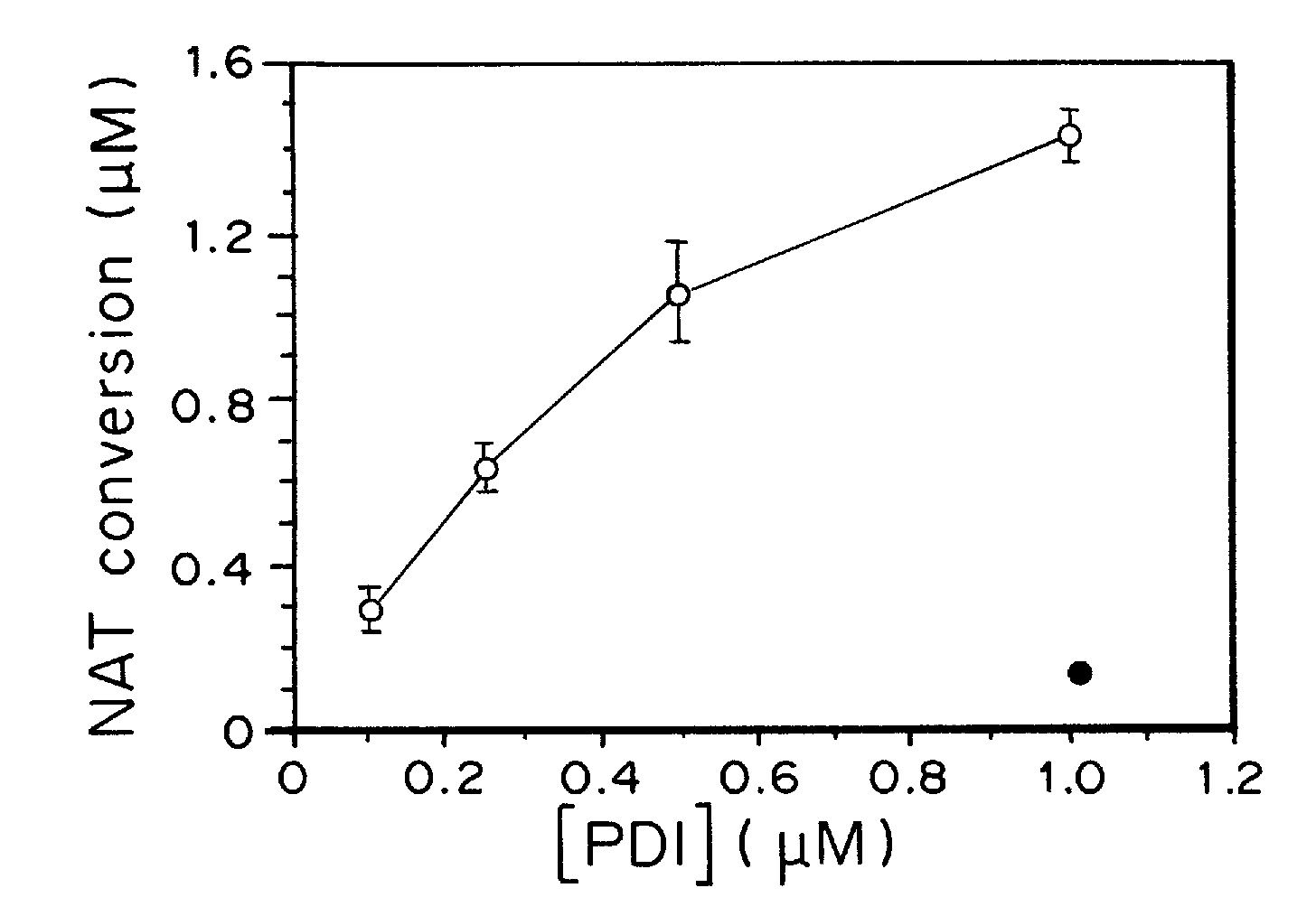

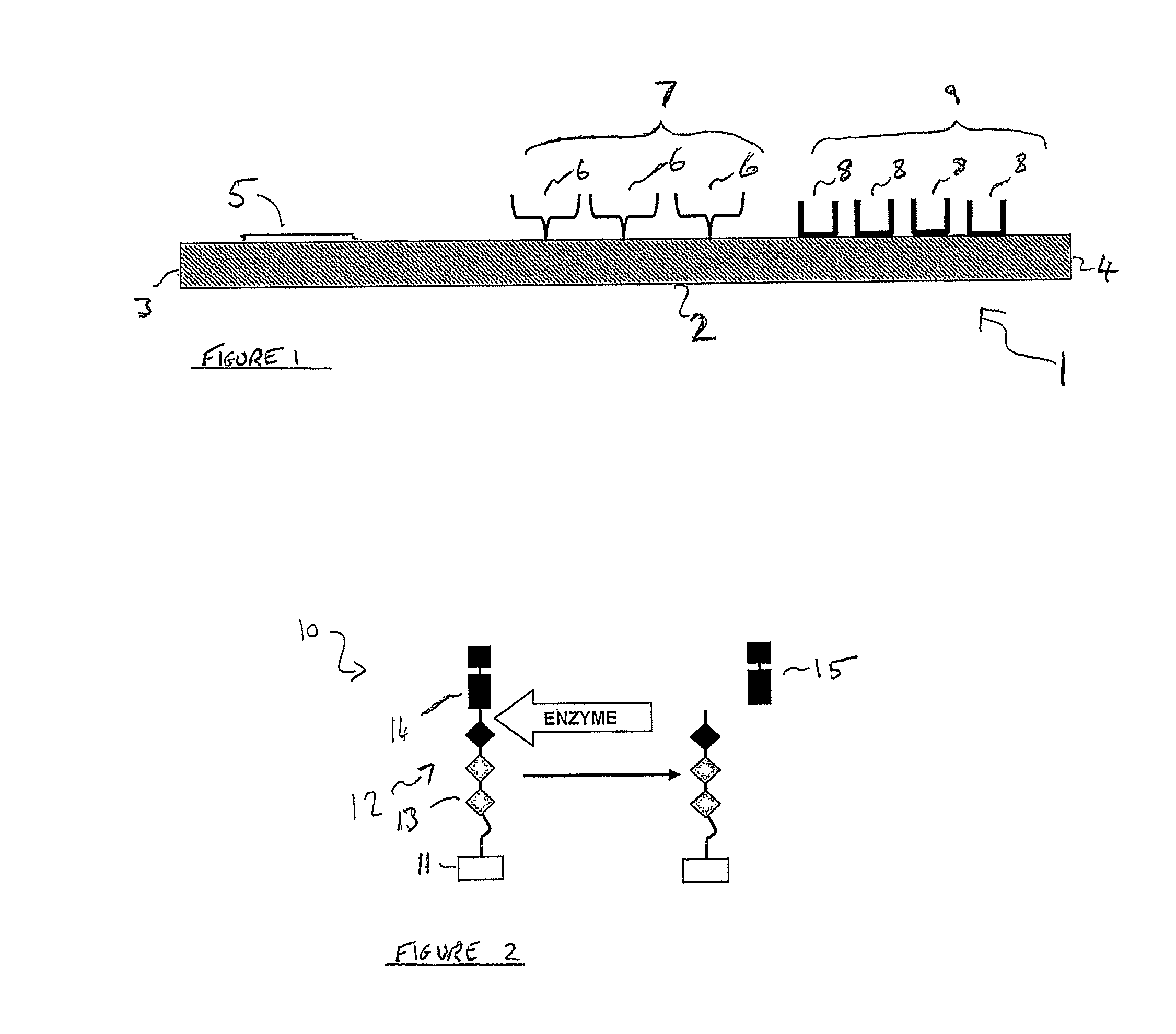

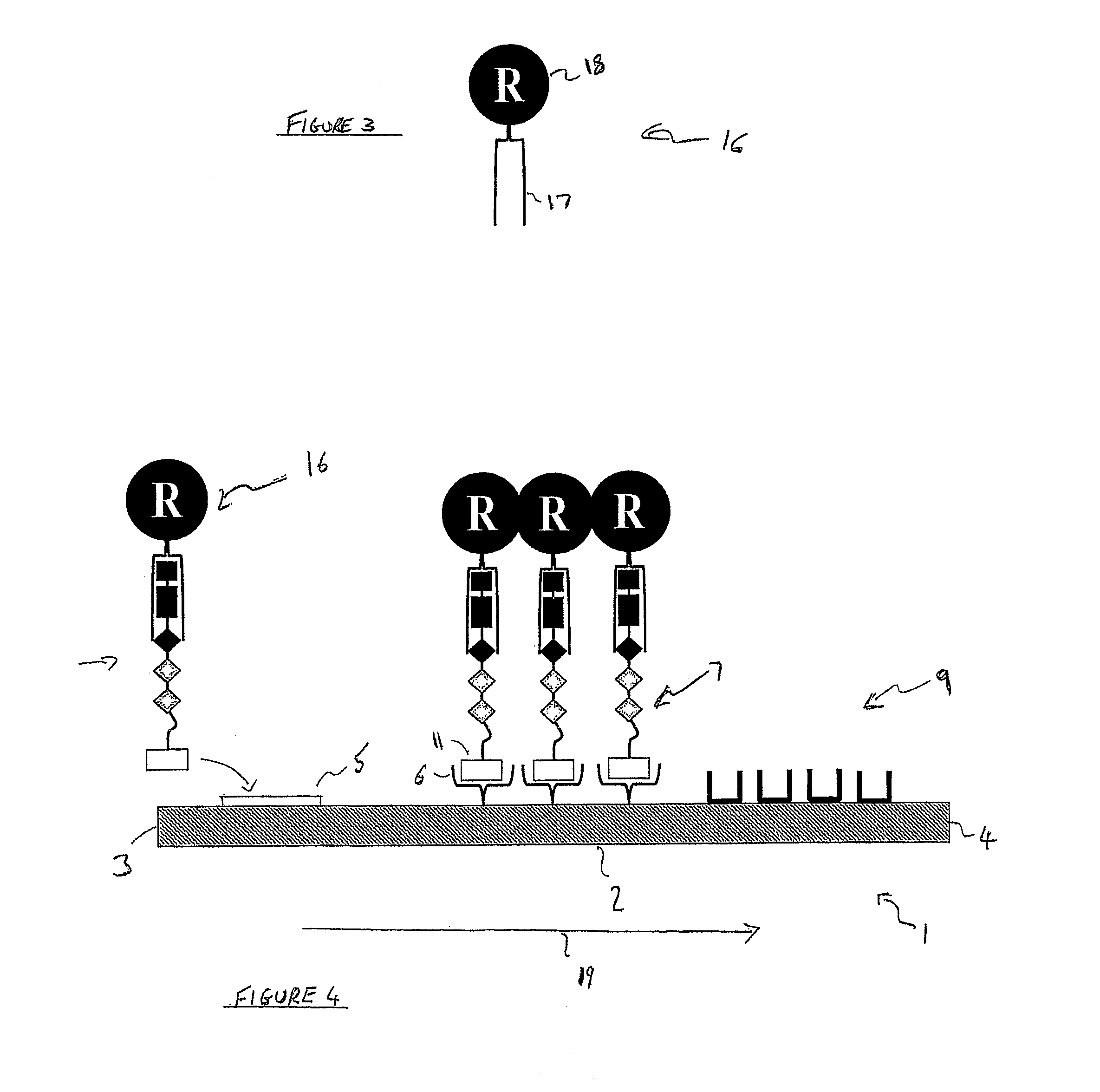

Enzyme detection device

ActiveUS8592167B2Low dissociation rateIncrease dissociation rateMicrobiological testing/measurementBiological testingMolecular bindingSubstrate recognition

An enzyme detection device (1) for detecting the presence, in a sample, of an enzyme capable of modifying a provided substrate (10). The device (1) comprises a substrate which has a modification region (14) that is sensitive to modification by the enzyme from an unmodified state to a modified state. The device (1) further comprises a substrate recognition molecule (16) which binds the modification region (14) in either the modified or the unmodified state. The modification region 14 of the substrate is preferentially bound by the substrate recognition molecule (16) as compared with the enzyme when mixed. The device further comprises a detectable label (18) coupled to the substrate recognition molecule (17).

Owner:MOLOGIC LTD

Device for photocatalytically degrading exhaust gas by electrodeless excimer lamp

ActiveCN104474885AChange luminous intensityChange luminous efficiencyDispersed particle separationCoaxial lineEngineering

The invention discloses a device for photocatalytically degrading exhaust gas by an electrodeless excimer lamp. A used reactor comprises three quartz medium layers, an inner electrode, an outer electrode and a high-voltage power supply. The three quartz medium layers comprise a first quartz tube, a second quartz tube and a third quartz tube which are coaxial and are sequentially arranged from inside to outside; the internal cavity of the first quartz tube is a reaction region III; a closed annular cavity is formed between the second quartz tube and the first quartz tube and serves as a gas filled region II; a reaction region I is formed between the third quartz tube and the second quartz tube. During the photocatalytic degradation of the exhaust gas, gas of the gas filled region II is excited to generate excimer UV light which radiates towards the direction of the reaction region I and the direction of the reaction region III, and the exhaust gas to be degraded fully passes through the reaction region I or reaction region III or enters the reaction region I and the reaction region III in a divided-flow manner and is degraded under the action of excimer ultraviolet radiation.

Owner:江苏龙环环境科技有限公司

Wet-strength wastepaper recycling double-pH-value chemical and mechanical pulping method

ActiveCN105568726AReduce consumptionImprove chemical reaction efficiencyPretreatment with water/steamPretreatment with alkaline reacting compoundsChemical treatmentFiber

The invention discloses a wet-strength wastepaper recycling double-pH-value chemical and mechanical pulping method. The method includes a material preparation section, a steaming section, a first extrusion and impregnation chemical and mechanical treatment section, a second extrusion and impregnation chemical and mechanical treatment section, a latency and re-defibering section and a purification, screening and concentration section. Wet-strength wastepaper fiber dissociation re-pulping is achieved while original pulp strength is not reduced through the mechanical strong force effect and the chemical treatment effect. Furthermore, on the two extrusion and impregnation chemical and mechanical treatment sections connected in series, a wet strength agent in wastepaper is oxidized under the acid condition firstly, hydrolysis is further promoted under the alkaline condition, chemical bonding between molecules of the wet strength agent and between the wet strength agent and pulp fibers is more effectively damaged, and the fiber dissociation rate and the re-pulping yield are effectively increased. The problems that the wet-strength wastepaper recycling pulping dissociation rate is low and strength is greatly decreased are solved, and continuous, large-scale, low-water-consumption and low-energy-consumption pollution-free and environment-friendly pulping can be achieved.

Owner:JIANGSU JINWO MACHINERY

Organic photoelectric detector based on mixed hole transport layer and preparation method of organic photoelectric detector

ActiveCN110504368AReduce defectsIncrease contact areaSolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsCharge carrier

The invention discloses an organic photoelectric detector based on a mixed hole transport layer. The organic photoelectric detector comprises a substrate, a conductive cathode, an electron transfer layer, an optical activity layer, a hole transport layer and a metal anode which are sequentially arranged from bottom to top, wherein the hole transport layer is formed by mixing MoO3 and chitosan andcarrying out vacuum evaporation; and the mass ratio of MoO3 to chitosan is 1: (0.03-0.2). The invention discloses a preparation method of the detector; the chitosan is doped in the MoO3 hole transportlayer, the migration rate of a hole can be filled while the hole transport layer and the optical activity layer are relatively large in contact area, the composite loss of the hole in the transport process is reduced, the hole can be more effectively transported, the carrier recombination rate is reduced, the dark current is reduced while the photocurrent is increased, and the overall performanceof the device is finally improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

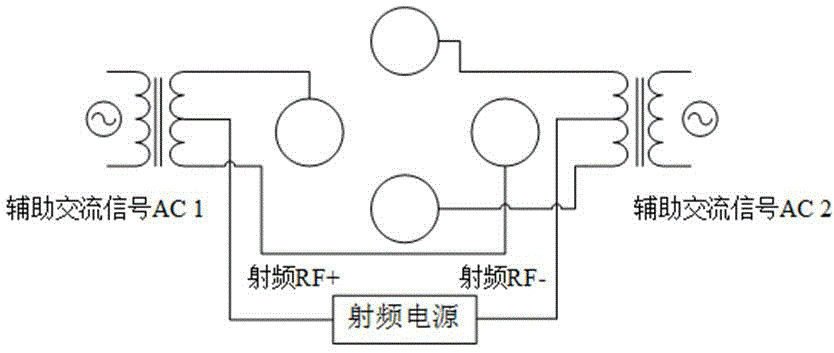

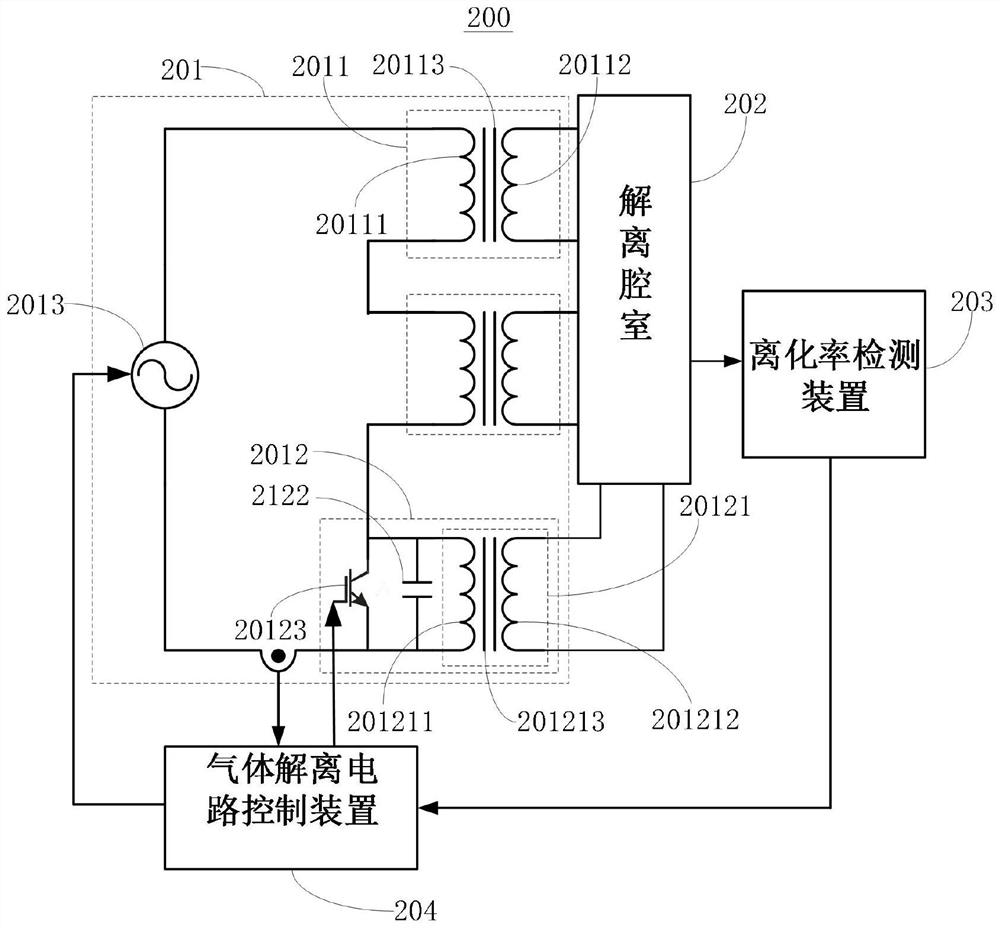

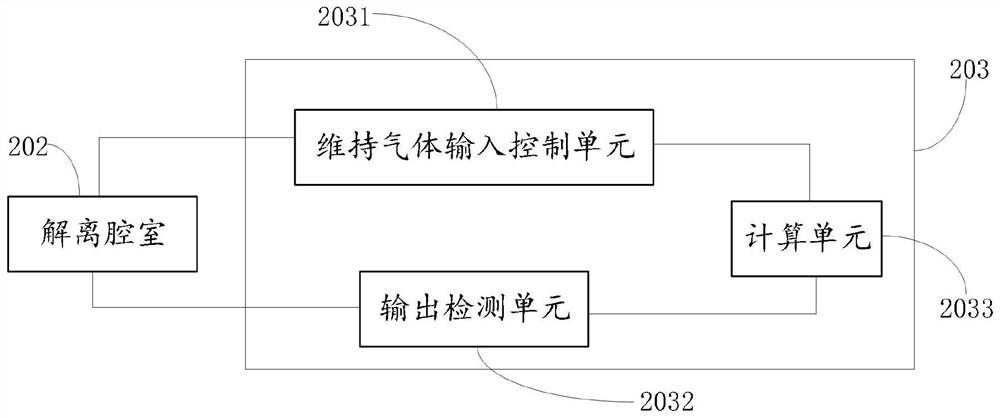

Gas dissociation circuit control device and system based on multi-coil coupling

PendingCN114501764AIncrease dissociation rateCircuit arrangementsPlasma techniqueParticle physicsMulti coil

The invention provides a gas dissociation circuit control device based on multi-coil coupling, which is applied to a gas dissociation system, the gas dissociation system comprises a dissociation chamber and a gas dissociation circuit, and the gas dissociation circuit control device comprises an ionization rate detection device used for detecting the ionization rate of gas in the dissociation chamber; the gas dissociation circuit control device is used for controlling the gas dissociation circuit according to the ionization rate, the reference ionization rate, the current of the gas dissociation circuit and the reference current, the gas dissociation circuit is adjusted through the detected ionization rate, and the gas dissociation rate is conveniently increased. The invention further provides a gas dissociation system.

Owner:江苏神州半导体科技有限公司

Method for photocatalytically degrading exhaust gas by electrodeless excimer lamp

ActiveCN104474886AChange luminous intensityChange luminous efficiencyDispersed particle separationCoaxial lineEngineering

The invention discloses a method for photocatalytically degrading exhaust gas by an electrodeless excimer lamp. A used reactor comprises three quartz medium layers, an inner electrode, an outer electrode and a high-voltage power supply. The three quartz medium layers comprise a first quartz tube, a second quartz tube and a third quartz tube which are coaxial and are sequentially arranged from inside to outside; the internal cavity of the first quartz tube is a reaction region III; a closed annular cavity is formed between the second quartz tube and the first quartz tube and serves as a gas filled region II; a reaction region I is formed between the third quartz tube and the second quartz tube. During the photocatalytic degradation of the exhaust gas, gas of the gas filled region II is excited to generate excimer UV light which radiates towards the direction of the reaction region I and the direction of the reaction region III, and the exhaust gas to be degraded fully passes through the reaction region I or reaction region III or enters the reaction region I and the reaction region III in a divided-flow manner and is degraded under the action of excimer ultraviolet radiation.

Owner:常州铭瑞环境检测有限公司

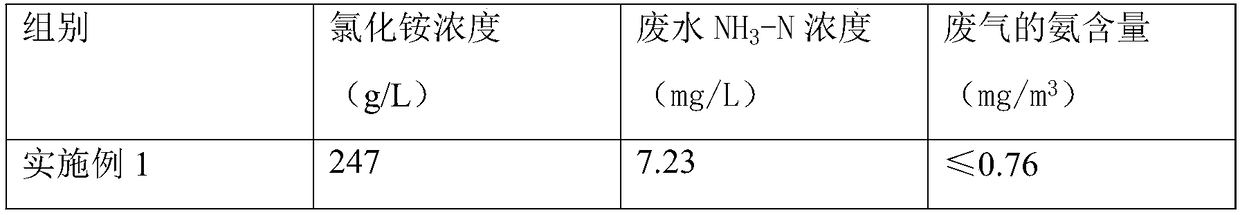

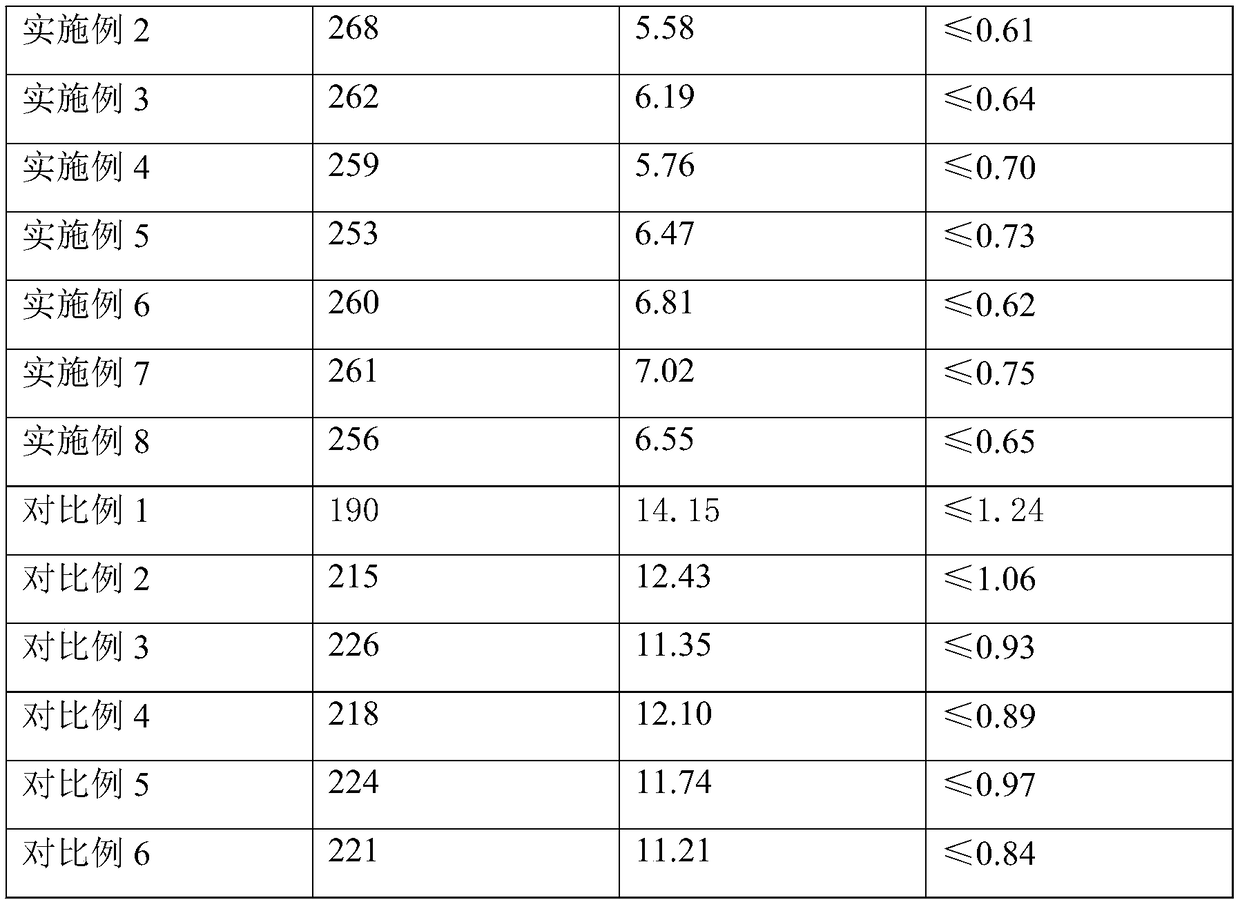

Method for recycling ammonium chloride in APT (ammonium paratungstate) production process

A method for recycling ammonium chloride in an APT (ammonium paratungstate) production process comprises steps of ammonia activation, stripping, hydrochloric acid spray and the like, wherein ammonia-nitrogen wastewater is adsorbed and pre-activated with pretreated activated carbon before ammonia activation, three-stage stripping is adopted, a small amount of nitrogen is introduced in the process,so that concentration of a sodium hydroxide solution can be reduced, ammonium chloride with higher concentration can be obtained, the requirement for recycling and preparing a desorption liquid is met, and further, NH3-N concentration of deaminated wastewater and ammonia content of discharged waste gas meet Integrated wastewater discharge standard (GB8978-1996) and Emission standards for odor pollutants (GB14554-93).

Owner:江西铜鼓有色冶金化工有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com