Corrugation self-check double-protection compensator

A compensator and corrugation technology, which is applied in the field of corrugated self-inspection double protection compensators, can solve the problems of affecting the flow and velocity of the medium, increasing the flow resistance of the medium, and affecting the service life of the compensator, so as to prolong the service life and avoid harm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

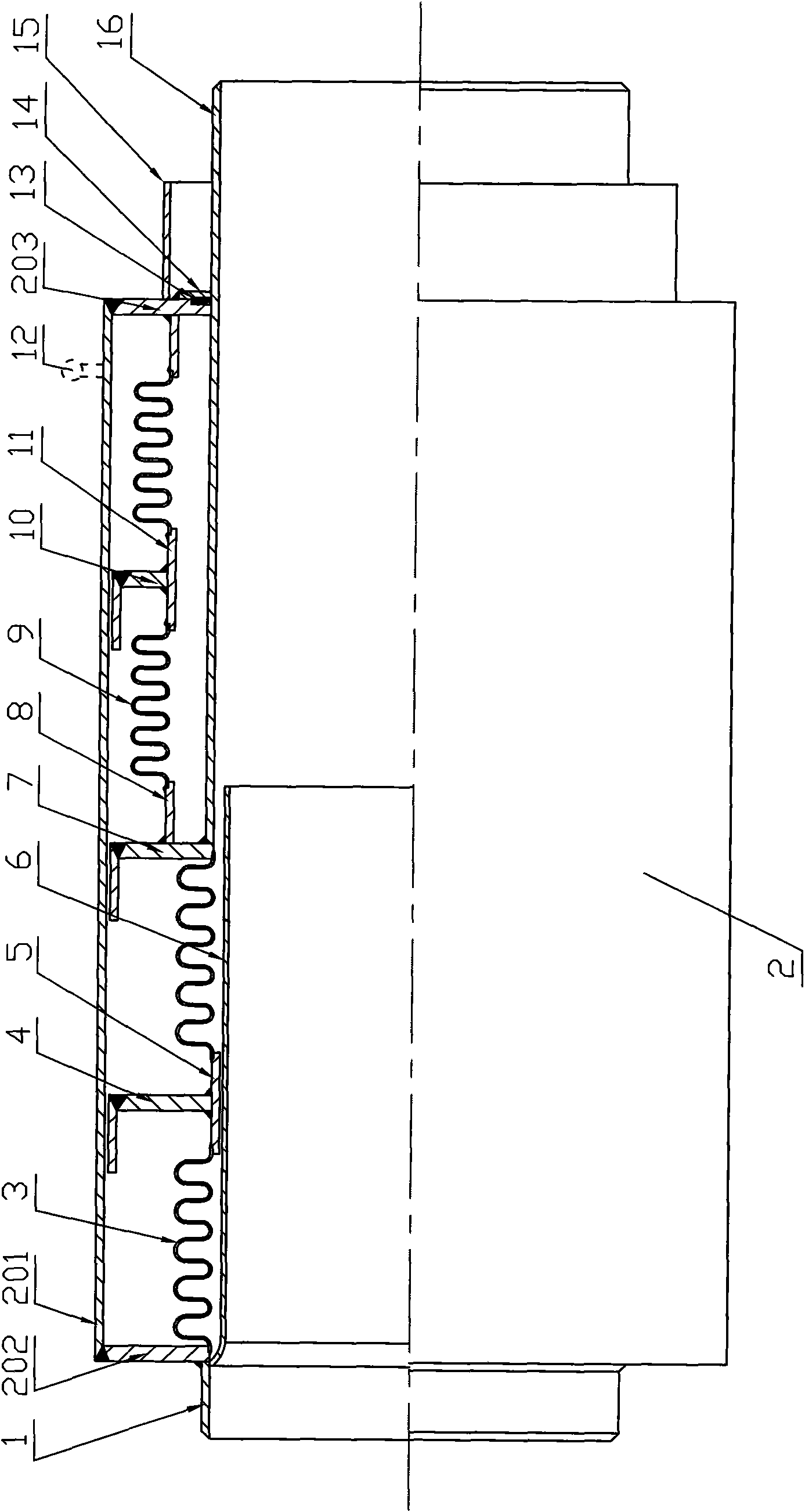

[0011] As shown in the figure, the corrugated self-test double-guaranteed compensator has a working bellows 3, and the two ends of the working bellows 3 are respectively provided with an inlet end pipe 1 and an outlet end pipe 16. The flow tube 6 and the left end of the guide tube 6 are welded on the inner wall of the inlet pipe 1, and the outer casing 2 is covered outside the working bellows 3, and the outer casing 2 is composed of the outer casing 201 and the inlets welded on the left and right ends of the outer casing 201 respectively. The flange 202 and the outlet flange 203 are composed of the inlet flange 202 welded between the working bellows 3 and the inlet pipe 1, the outlet flange 203 set on the outlet pipe 16, and the outlet flange 203 and the outlet pipe 16 is provided with a sealing ring 13, a sealing gland 14 and a dust-proof pipe cover 15 are welded on the outer end surface of the outlet flange 203, the sealing gland 14 is pressed on the sealing ring 13, and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com