Plasma coupling light catalytic unit assembly and gas purifier therewith

A photocatalytic unit and plasma technology, which is applied in household heating, lighting and heating equipment, space heating and ventilation, etc. It can solve the problems of difficult discharge of chemical components, complicated electrode processing technology, and inability to achieve complete decomposition. , to achieve the effects of reduced production cost, improved processing effect, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

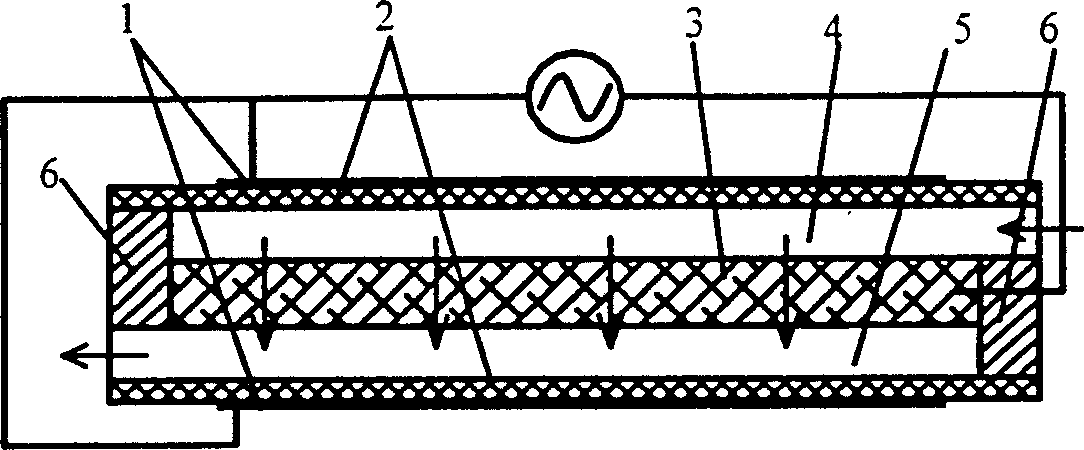

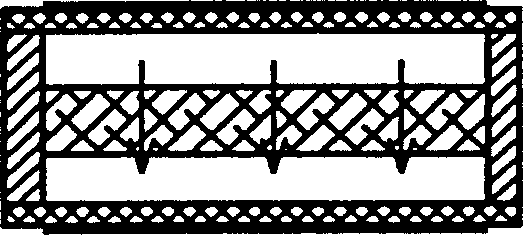

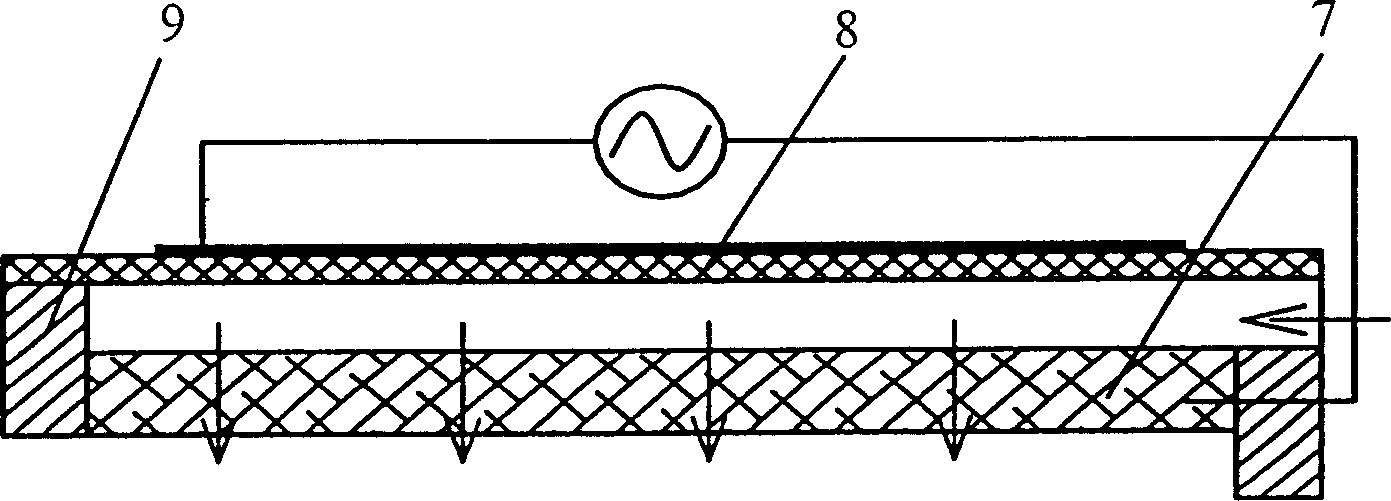

[0023] see figure 1 , figure 2 , two parallel dielectric barrier layers 2 are ceramic flat plates with a thickness of 1 mm, and a copper film with a thickness of 0.02-0.1 mm is plated on the outer side of the ceramic plate 2 (the back side of the discharge gap) as the electrode 1, The flat photocatalytic porous body 3 is a mesh made of copper wire with a diameter of about 0.5 mm. The mesh is about 2 mm, and 12 pieces are stacked. The total thickness is about 6 mm. The photocatalyst is attached to the mesh by coating. The film is titanium oxide TiO 2(anatase type), there is a gap of 5 mm between the dielectric barrier layer 2 and the photocatalytic porous body 3 respectively. The sealing member 6 made of engineering plastics connects the two planar photocatalytic porous bodies into a whole, and forms a sealed inner space. The air inlet 4, the air outlet 5 on the side wall and the holes on the porous photocatalyst 3 constitute a smooth airflow channel, and the flow direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com