Hydraulic turbine generator

A water turbine generator and water wheel technology, which is applied to hydroelectric power generation, engine components, machines/engines, etc., can solve the problem of reducing the utilization rate of water kinetic energy, the load capacity of the runner, reducing the impact of the flow channel on the runner, and the flow rate of the runner. Specific speed and other issues to achieve the effect of improving power generation efficiency, maintaining tail water flow rate, increasing specific speed and load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

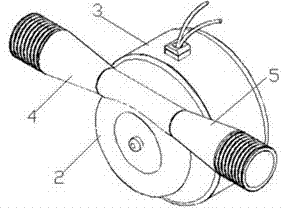

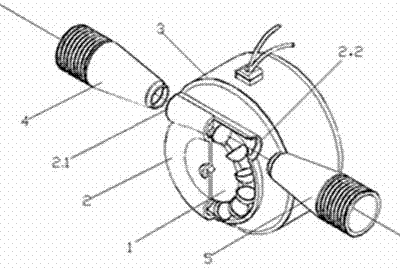

[0019] See attached Figure 1-6 , the present embodiment includes a water wheel chamber 2, a power generation chamber 3, and also includes a water guide pipe 4 and a draft pipe 5. A runner 1 is installed in the water wheel chamber 2, and the runner 1 is composed of a wheel disc 1.1 and a bucket 1.2. The water wheel Chamber 2 is provided with a water inlet 2.1 and a water outlet 2.2. The water inlet 2.1 and the water outlet 2.2 have the same caliber, the axes are coincident, and the directions are opposite. The reducer 4.1, the large-mouth joint 4.2 and the small-mouth joint 4.3 are formed. The shrinkage angle of the reducer 4.1 is 16° and the axial length is about 35mm. The inner diameter of the large mouth of the pipe 4.1 is equal to 20mm, and the inner diameter of the small mouth is set to 10mm. The inner diameters of the water inlet 2.1 and the water outlet 2.2 of the water wheel chamber and the inner diameter of the annular cavity 2.3 surrounding the bucket 1.2 of the wate...

Embodiment 2

[0021] See attached Figure 7 , compared with embodiment 1, the difference mainly lies in that the runner 1 adopts non-directional blades 1.2, therefore, there is no need to select product equipment designed in different directions according to the direction of the pipeline during installation, that is, the water guide pipe 4 and the The draft tube 5 can be interchanged, which has the advantage of being more convenient to install compared with Embodiment 1. All the other unmentioned parts are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com