Double-inlet guide vane and volute combined axially-split multistage centrifugal pump

A combined, double-inlet technology, applied in the field of centrifugal pumps, can solve problems affecting the dynamic balance of centrifugal pump rotors, low working efficiency of centrifugal pumps, and difficult disassembly of guide vanes, etc., to achieve volume reduction, structure simplification, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings:

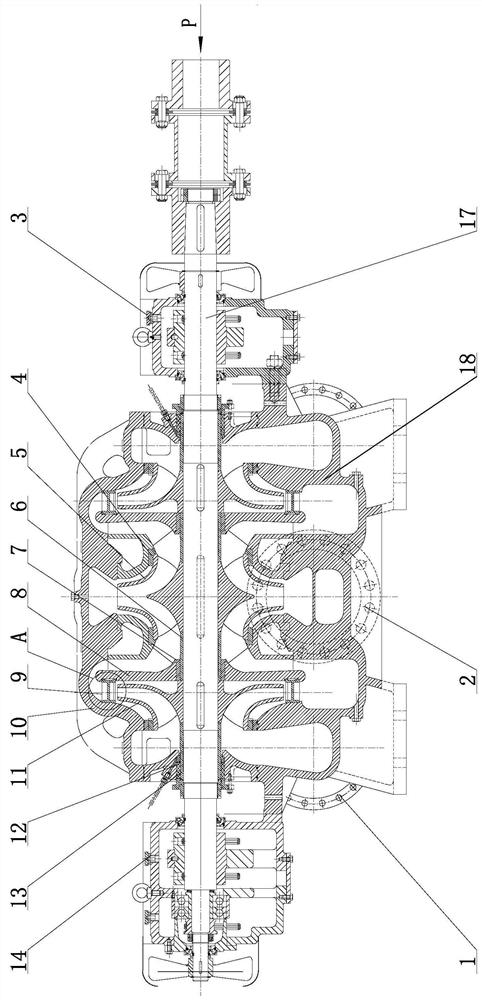

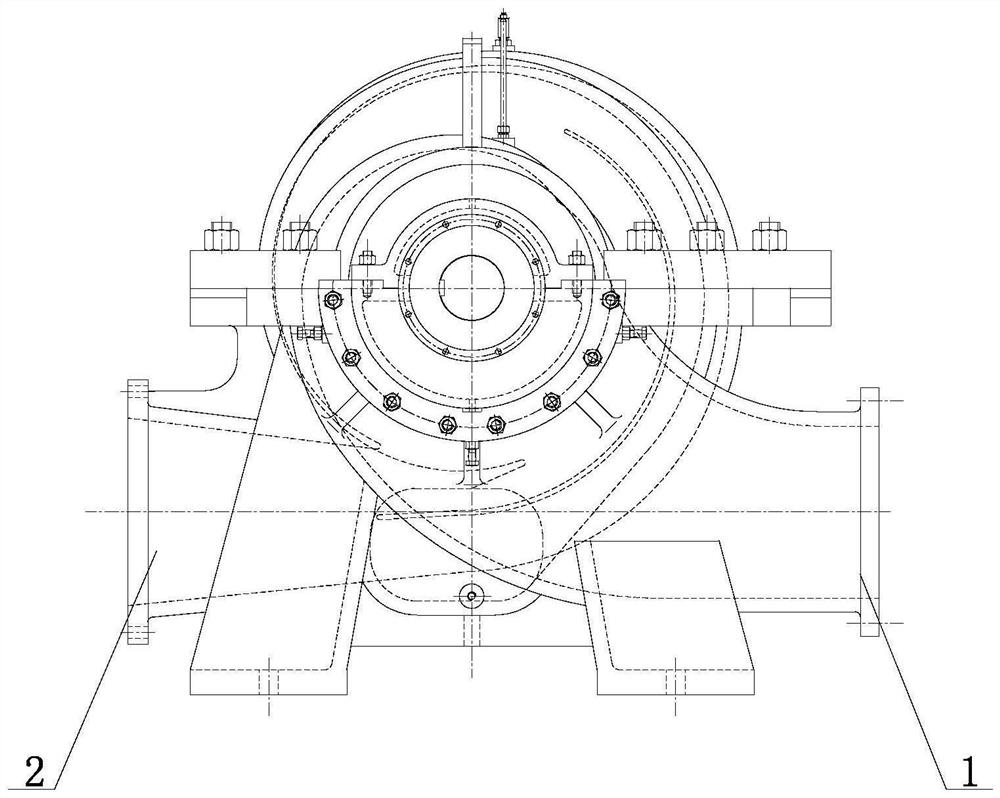

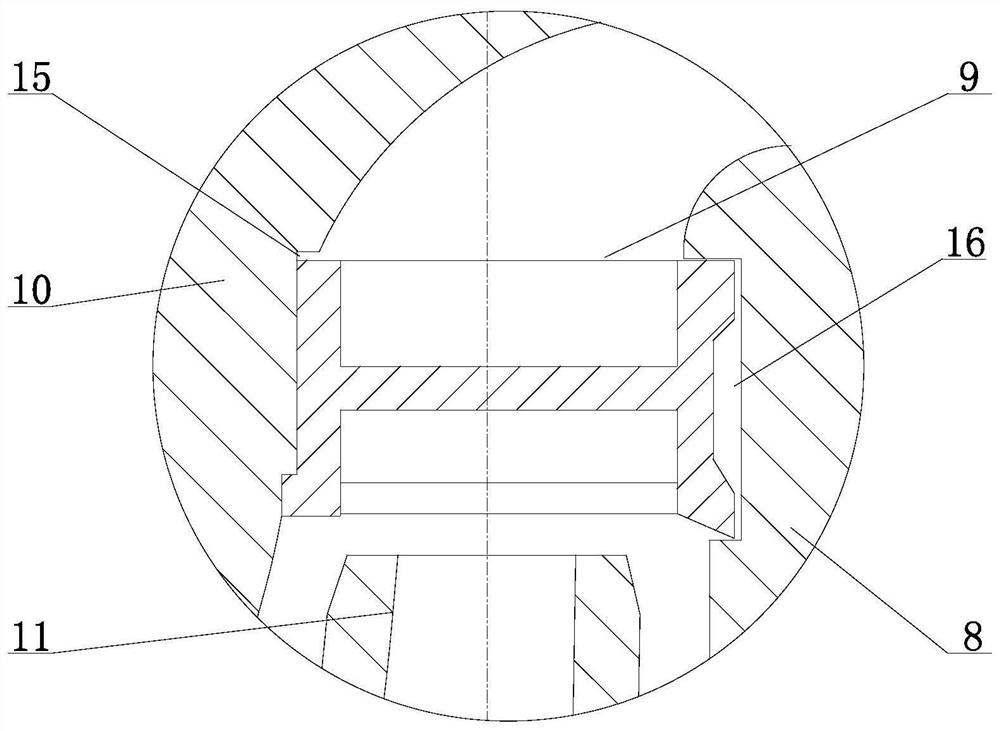

[0021] like Figure 1 - Figure 4 As shown, the dual-inlet guiding and volute of the present invention are combined with a plurality of stage multi-stage centrifugal pumps, including a pump shaft 17, a driving end bearing assembly 3, an overcurrent assembly, and a non-driving end bearing assembly 14, a pump shaft. 17 sequentially passes through the drive end bearing assembly 3, overcurrent assembly, and non-drive end bearing assembly 14, the overcurrent assembly includes a pump cover 10 and a pump body 18, and the pump body 18 is provided with a pump outlet 2, and the pump body 18 ends. The corresponding volute is provided with a pump inlet 1, the pump cover 10 and the pump shaft 17 in the pump shaft 17 in the pump body 18 in the pump body 18, and the pump shaft 5, the pump cover 10 and the pump body 18 two The pump shaft 17 in the corresponding volute of the volute is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com