Double-shaft internally tangent type bidirectional transmission oil-gas multiphase pump

An oil and gas mixed pump and bidirectional transmission technology, applied in non-variable-capacity pumps, pumps, machines/engines, etc., can solve the problems of high vibration and noise, long axial length of mixed pump, and large volume of the pump body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

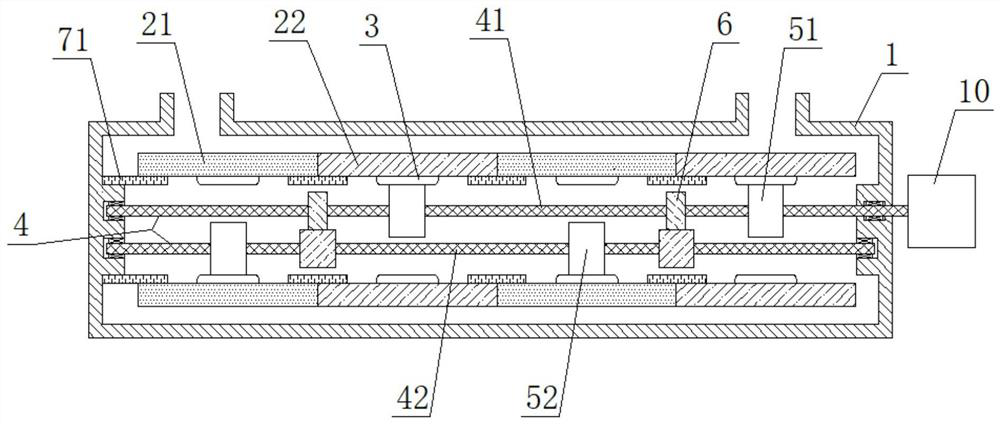

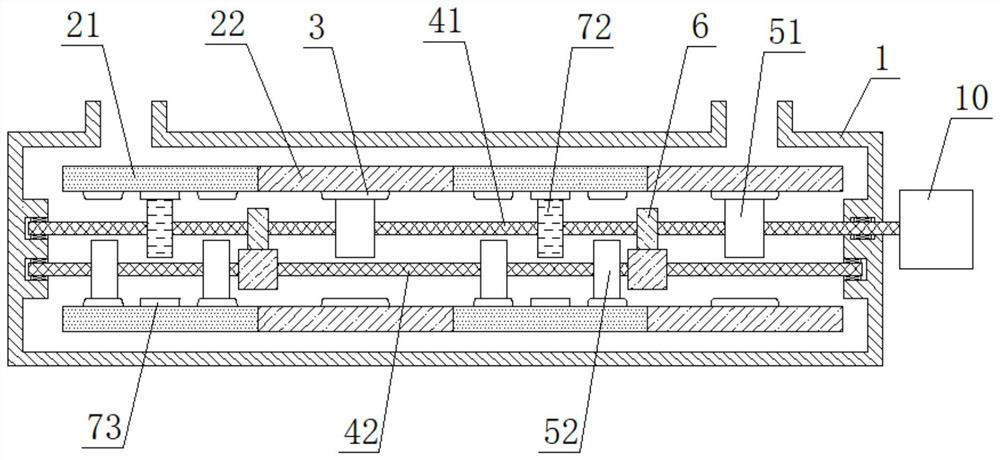

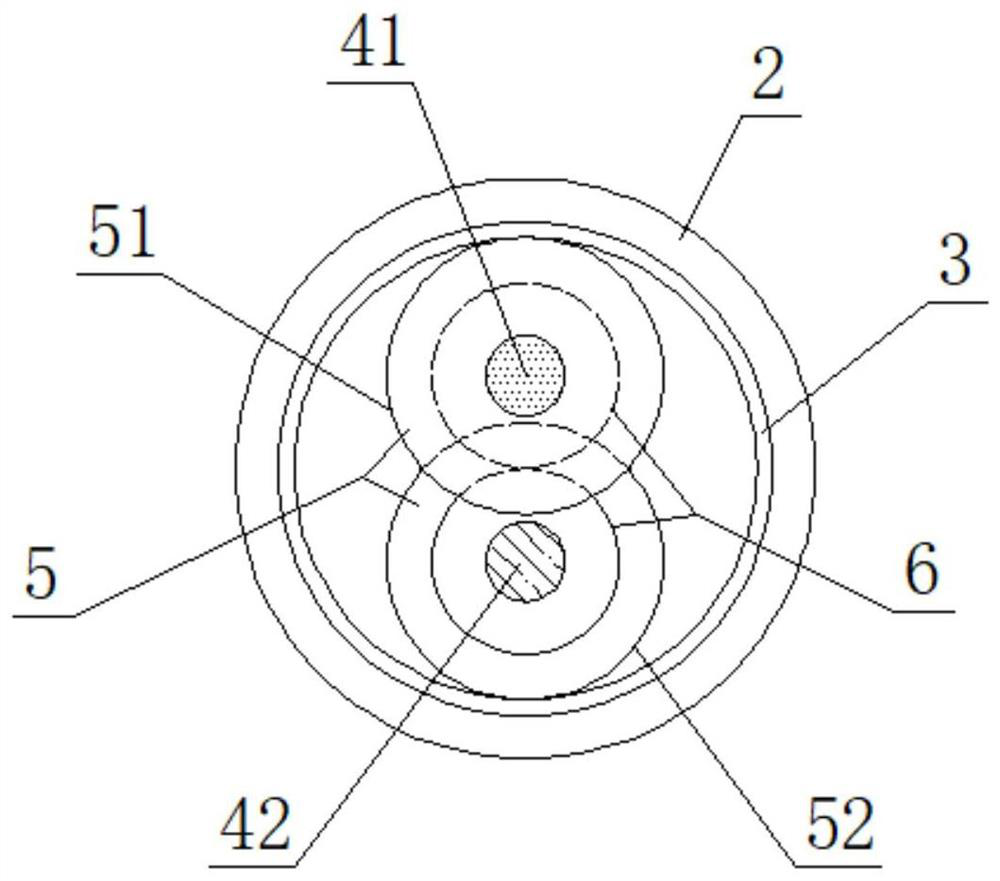

[0015] As shown in the figure, a dual-shaft inscribed two-way transmission oil-gas mixed transmission pump includes a pump body 1 and impellers 2 located in the pump body 1, wherein the impellers 2 include forward impellers 21 and reverse impellers arranged alternately. To the impeller 22, the blade inlet on the latter impeller 2 is designed with the blade outlet conditions on the previous impeller 2, a rack 3 is provided on the inner wall of the impeller 2, and upper and lower blades are arranged in the pump body 1. Two rotating shafts 4, one end of which one rotating shaft 4 is connected with motor 10, is provided with driving gear 5 and transmission gear 6 on described rotating shaft 4, wherein the lower driving gear 52 on the lower rotating shaft 42 is connected with the forward impeller 21 The rack 3 is inscribed and meshed, the upper driving gear 52 on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com