Turning lathe

A lathe and turning technology, used in metal processing machinery parts, maintenance and safety accessories, grain processing, etc., can solve the problems of easy dispersion of debris and difficult cleaning, and achieve the effect of strengthening the cutting effect and strengthening the cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

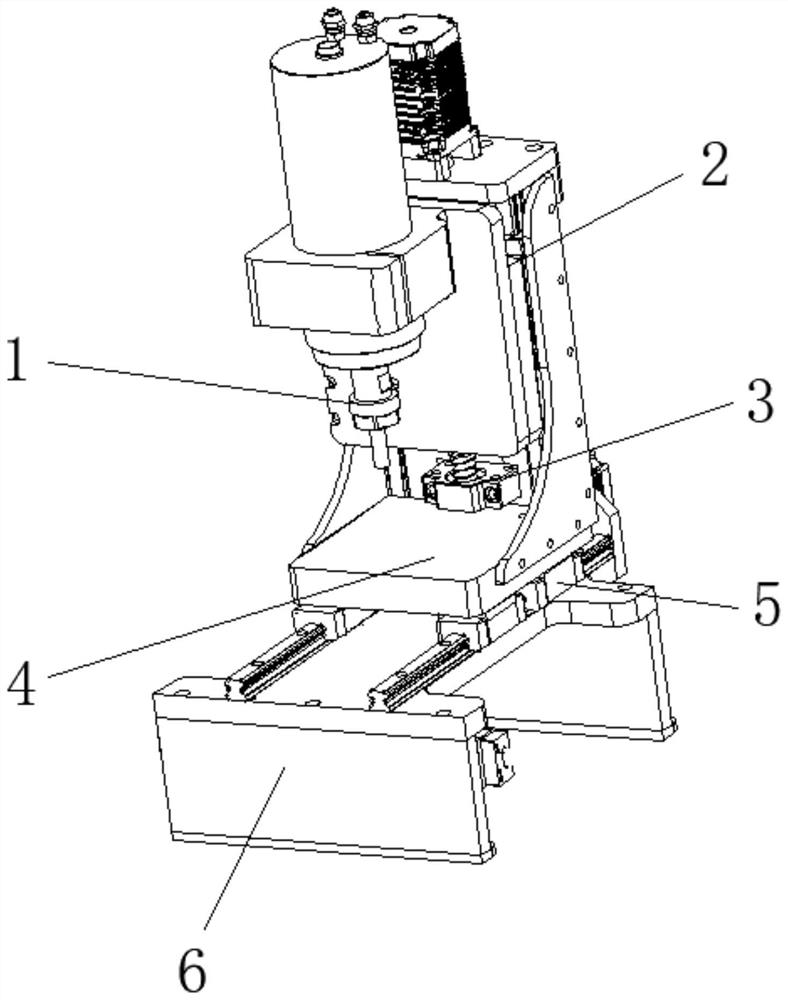

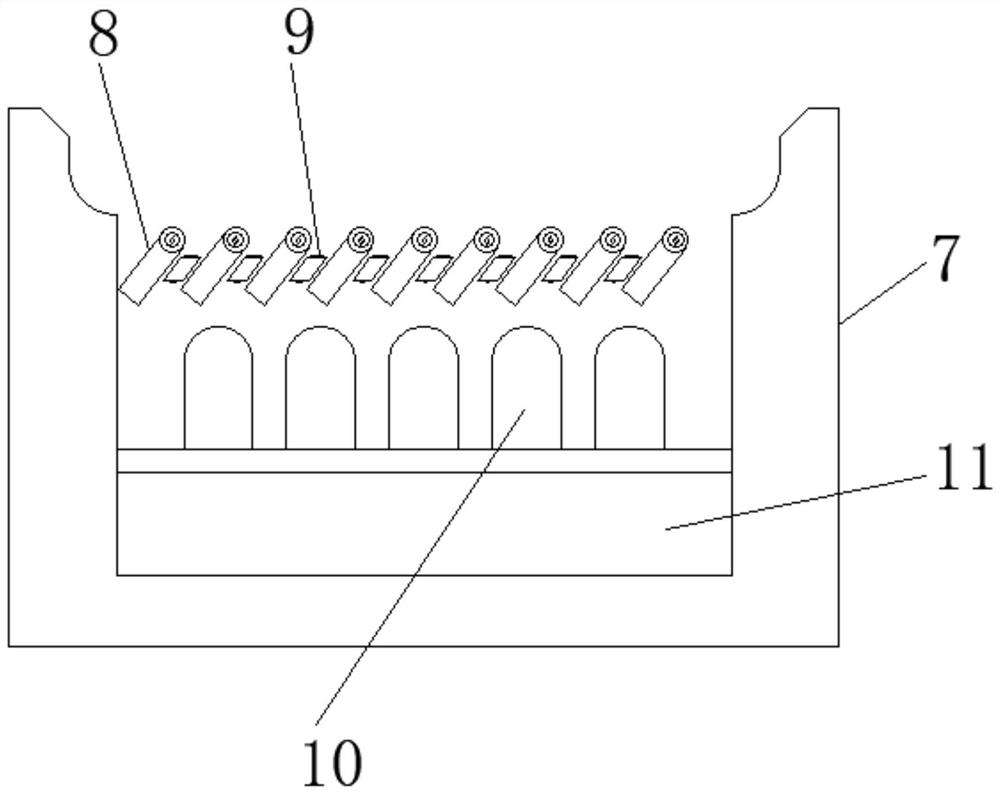

[0029] Such as Figure 1-7 As shown, the embodiment of the present invention provides a turning lathe, including a processing head 1, a mounting plate 2, a fixed plate 3, a pressing plate 4, a movable table 5 and a base plate 6, and one end of the processing head 1 is connected to the mounting plate 2 through a coupling. The rotating motor is connected, the inside of the mounting plate 2 has a mounting groove, the inner wall of the mounting groove is provided with a cooling lubricating fluid box, the movable table 5 is fixedly connected with the top outer wall of the bottom plate 6, and the movable table 5 is provided with slide rails, and the mounting plate The bottom of 2 is provided with a sliding plate, and the sliding plate is compatible with the slide rail, the fixed plate 3 is movably connected with the outer wall of one end of the mounting plate 2, and the pressing plate 4 is arranged under the fixed plate 3 .

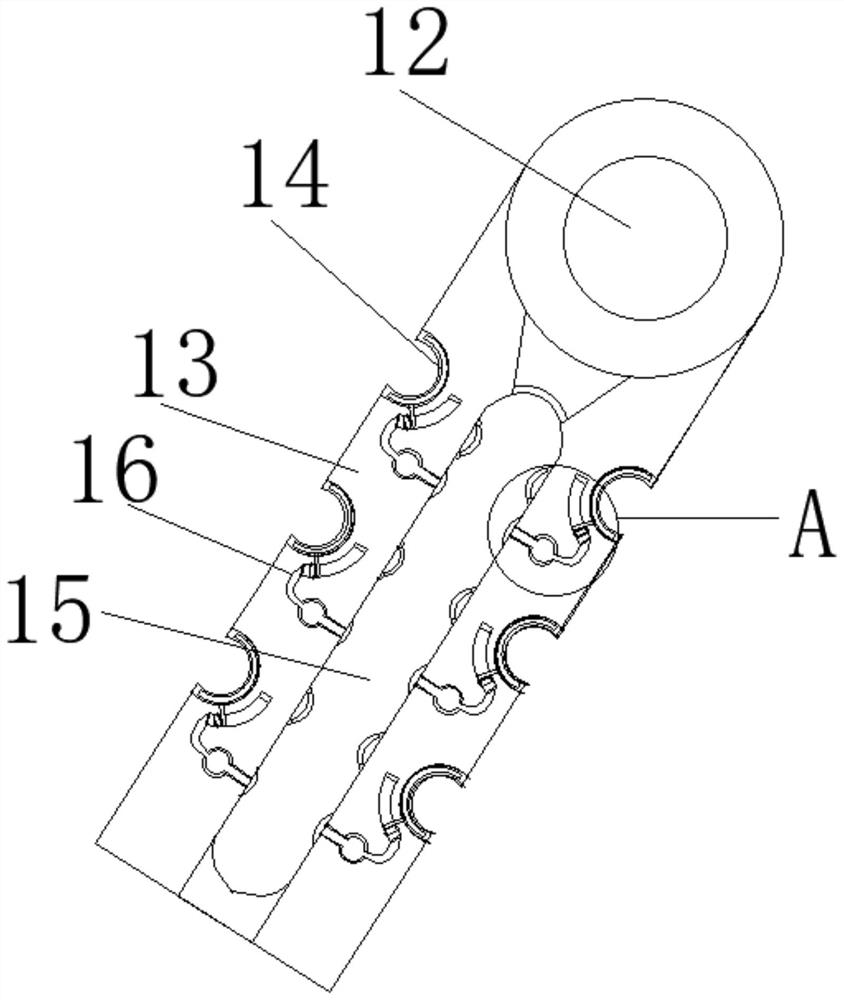

[0030] In the present invention, the pressing plate 4 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com