Multifunctional finishing agent for costume, as well as preparation and using method of multifunctional finishing agent

A multi-functional, finishing agent technology, applied in the fields of clothing and polymers, can solve the problems of insufficient bonding firmness, affecting the flexibility and air permeability of the fabric, sacrificing the air permeability of the fabric, etc., to achieve the effect of stable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

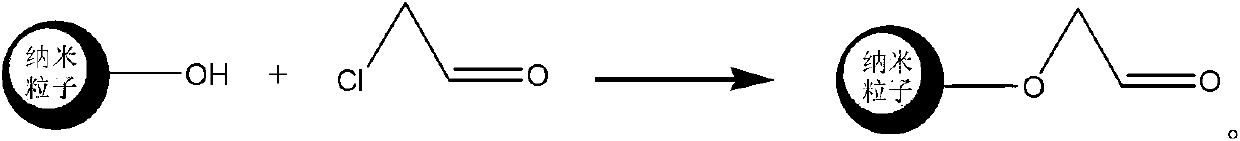

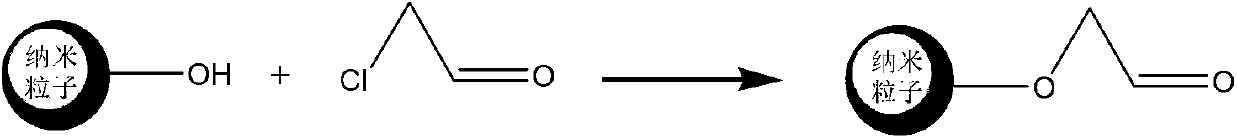

[0026] (1) Surface-modified nano-titanium dioxide particles: 100ml ethanol, 20g titanium dioxide nanoparticles (3nm), 1g chloroacetaldehyde, 80°C, nitrogen protection, reflux of the condenser tube, and react for 2 hours to prepare surface-modified active titanium dioxide nanoparticles.

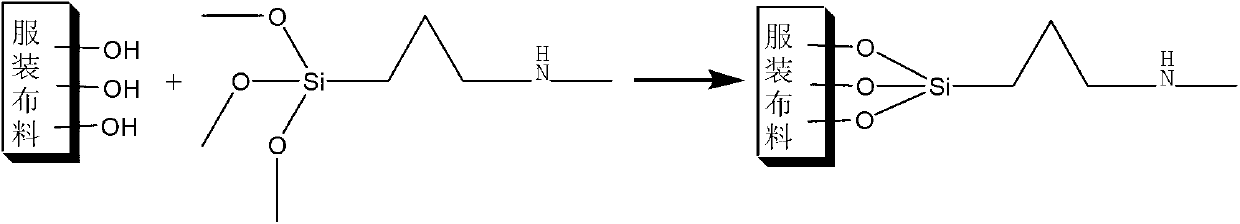

[0027] (2) Clothing fabric for surface modification: Soak the clothing fabric in methylaminopropyl trimethylsilane acetone solution (0.1g / ml) at 50°C for 2 hours. A surface-modified active garment fabric is produced.

[0028] (3) Apply the above-mentioned active titanium dioxide nanoparticle solution on the clothing fabric, heat it at 60° C. for 15 minutes, and wash the fabric to obtain a self-cleaning, mildew-proof and antibacterial clothing fabric.

Embodiment example 2

[0030] (1) Surface-modified nano-titanium dioxide particles: 100ml ethanol, 20g titanium dioxide nanoparticles (3nm), 0.1g chloroacetaldehyde, 40°C, nitrogen protection, condensing tube reflux, and react for 6 hours to prepare surface-modified active titanium dioxide nanoparticles .

[0031] (2) Clothing fabric for surface modification: Soak the clothing fabric in methylaminopropyl trimethylsilane acetone solution (0.1g / ml) at 30°C for 3 hours. A surface-modified active garment fabric is produced.

[0032] (3) Apply the above-mentioned active titanium dioxide nanoparticle solution on the clothing fabric, heat it at 60° C. for 15 minutes, and wash the fabric to obtain a self-cleaning, mildew-proof and antibacterial clothing fabric.

Embodiment example 3

[0034] (1) Surface-modified nano-titanium dioxide particles: 100ml ethanol, 20g titanium dioxide nanoparticles (3nm), 0.5g chloroacetaldehyde, 60°C, nitrogen protection, reflux of the condenser tube, and react for 4 hours to prepare surface-modified active titanium dioxide nanoparticles .

[0035] (2) Clothing fabric for surface modification: Soak the clothing fabric in methylaminopropyl trimethylsilane acetone solution (0.5g / ml) at 30°C for 3 hours. A surface-modified active garment fabric is produced.

[0036] (3) Apply the above-mentioned active titanium dioxide nanoparticle solution on the clothing fabric, heat it at 60° C. for 15 minutes, and wash the fabric to obtain a self-cleaning, mildew-proof and antibacterial clothing fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com