Preparation method of transparent conductive film

A transparent conductive and adhesive film technology, which is applied in the direction of conductive adhesives, chemical instruments and methods, film/sheet adhesives, etc., can solve problems such as expensive equipment, poor bending resistance of films, and complicated processes, and achieve Low surface resistivity, simple film forming process, and high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

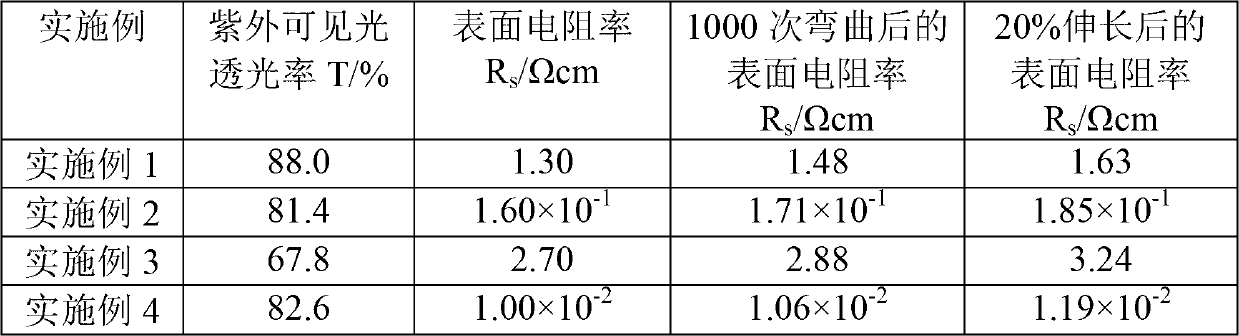

Examples

Embodiment 1

[0012] (1) Take 1mL of 0.05mol / L ethanol solution of silver nanowires, drop the above solution on the surface of the transparent PET film at room temperature, and then use a 200μm scraping rod to scrape a 200μm ethanol solution film layer of nanosilver wires on the surface of the PET film ;

[0013] (2) Dry the ethanol solution thin film layer of 200 μm silver nanowires in step (1) at 60°C for 10 minutes to completely volatilize the ethanol;

[0014] (3) Cover the surface of the volatilized PET film obtained in step (2) with a layer of oiled paper, then transfer the film to a flat hot press at 190°C, and perform hot pressing treatment under a pressure of 5 MPa. The time is controlled as 60s, then take it out, let it cool down naturally, remove the oil-faced paper, and the conductive network of silver nanowires is all embedded in the surface of the PET film, so as to obtain the transparent conductive adhesive film.

Embodiment 2

[0016] (1) Take 1mL of 0.25mol / L ethanol solution of silver nanowires, drop the above solution on the surface of transparent PET film at room temperature, and then use a 200μm scraping rod to scrape a 200μm ethanol solution film layer of nanosilver wires on the surface of PET film ;

[0017] (2) Dry the ethanol solution thin film layer of 200 μm silver nanowires in step (1) at 60°C for 10 minutes to completely volatilize the ethanol;

[0018] (3) The surface of the volatilized PET film obtained in step (2) is covered with a layer of oiled paper, and then the film is transferred to a flat-plate hot press at 200°C, and hot-pressed at a pressure of 10 MPa, and the time is controlled as 180s, then take it out, let it cool down naturally, take off the oil-faced paper, and the conductive network of silver nanowires is all embedded in the PET film surface, and promptly obtains described transparent conductive adhesive film.

Embodiment 3

[0020] (1) Take 1mL of 0.5mol / L ethanol solution of silver nanowires, drop the above solution on the surface of transparent PET film at room temperature, and then use a 200μm film scraping rod to scrape a 200μm ethanol solution film layer of nano silver wires on the surface of PET film ;

[0021] (2) Dry the ethanol solution thin film layer of 200 μm silver nanowires in step (1) at 60°C for 10 minutes to completely volatilize the ethanol;

[0022] (3) The surface of the volatilized PET film obtained in step (2) is covered with a layer of oiled paper, and then the film is transferred to a flat-plate hot press at 210°C, and heat-pressed at a pressure of 15 MPa. The time is controlled as 300s, then take it out, let it cool down naturally, remove the oil-faced paper, and the conductive network of silver nanowires is all embedded in the surface of the PET film to obtain the transparent conductive adhesive film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com