Antistatic polyurethane elastomer and preparation method thereof

A polyurethane elastomer and antistatic technology, which is applied in the field of polymer material synthesis, can solve the problems of reducing material strength, easy agglomeration of carbon black, and difficulty in dispersing, and achieve the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

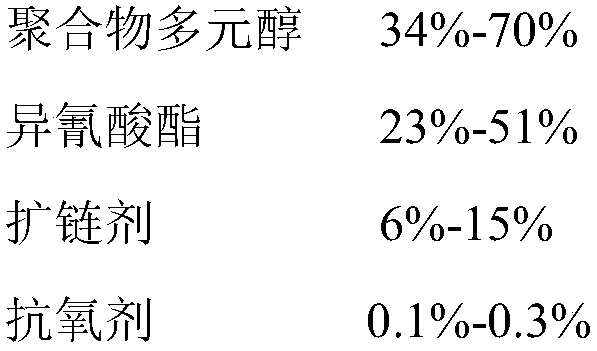

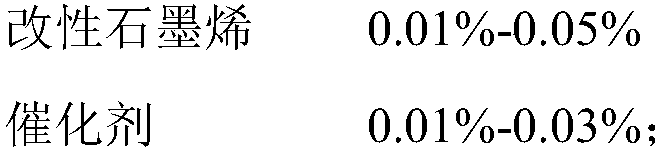

[0032] An antistatic polyurethane elastomer, which is mainly prepared from the following raw materials by weight fraction:

[0033]

[0034] (1) polybutylene adipate diol (M-1000), antioxidant 1010, organotin joins in reactor A by weight percentage, nitrogen protection, keep reactor A temperature is 95 ℃, and in Stir well in the reaction kettle A evenly. Add MDI to reactor B by weight percentage, protect the reactor with nitrogen, and keep the temperature of the reactor at 40°C.

[0035] (2) Add 1,4-butanediol and graphene oxide into reaction kettle C according to weight percentage, and disperse in ultrasonic for 2 hours to form graphene oxide-1,4-butanediol dispersion, nitrogen protection, keep The temperature of the reaction kettle was 55°C.

[0036] (3) When the temperature of each reactor is stable, through the perfusion system with accurate metering, the raw material components in reactors A, B and C are accurately metered by the metering pump according to the weight...

Embodiment 2

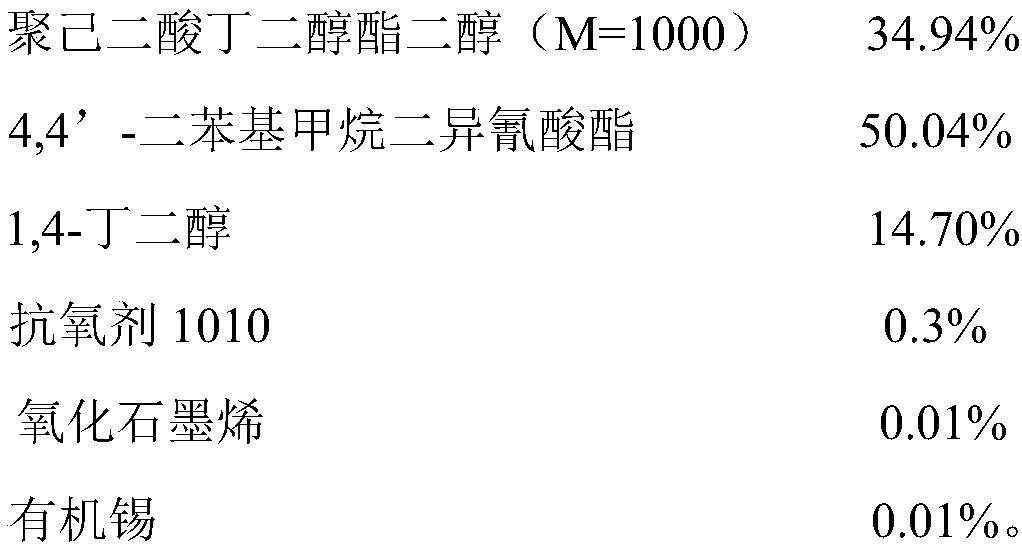

[0038] An antistatic polyurethane elastomer, which is mainly prepared from the following raw materials by weight fraction:

[0039]

[0040]The specific preparation process is the same as that of Example 1, the difference being that the insulation temperature of reactor A is 100°C, the insulation temperature of reactor B is 50°C, the insulation temperature of reactor C is 50°C, and the hydroxylated modified graphene and 1,6 - The hexanediol ultrasonic dispersion time is 4 hours to form a hydroxylated modified graphene-1,6-hexanediol dispersion; the temperature of the twin-screw extruder is 210° C., and the screw speed is 190 rpm.

Embodiment 3

[0042] An antistatic polyurethane elastomer, which is mainly prepared from the following raw materials by weight fraction:

[0043]

[0044] The specific preparation process is the same as in Example 1, the difference is that the temperature of the reactor A is 98°C, the temperature of the reactor B is 60°C, the temperature of the reactor C is 58°C, and the amination modified graphene and 1,6 - The hexanediol ultrasonic dispersion time is 4 hours to form an aminated modified graphene-1,6-hexanediol dispersion; the temperature of the twin-screw extruder is 180° C., and the screw speed is 180 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com