Nitrogen dioxide gas sensor and preparation and testing methods of nitrogen dioxide gas sensor

A gas sensor and nitrogen dioxide technology, applied in the sensor field, can solve the problems of deteriorating the properties of organic semiconductor polymers, etc., and achieve the effects of favorable electrical performance, low production cost, and improved mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

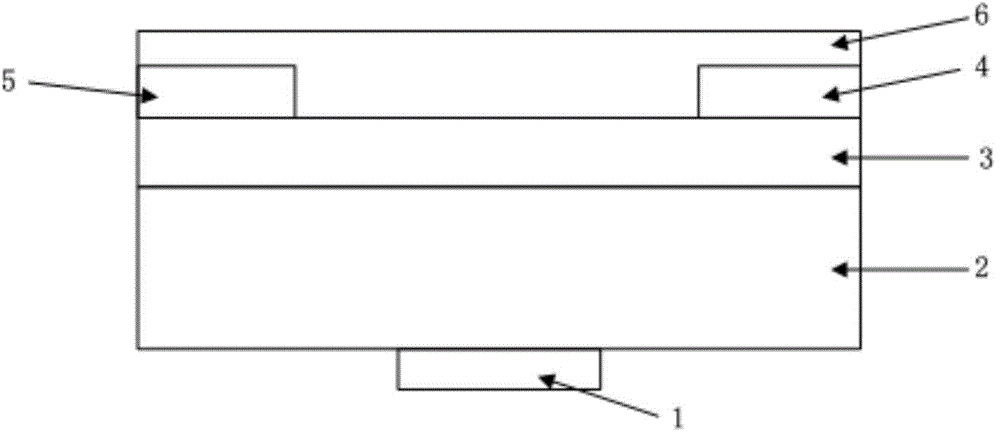

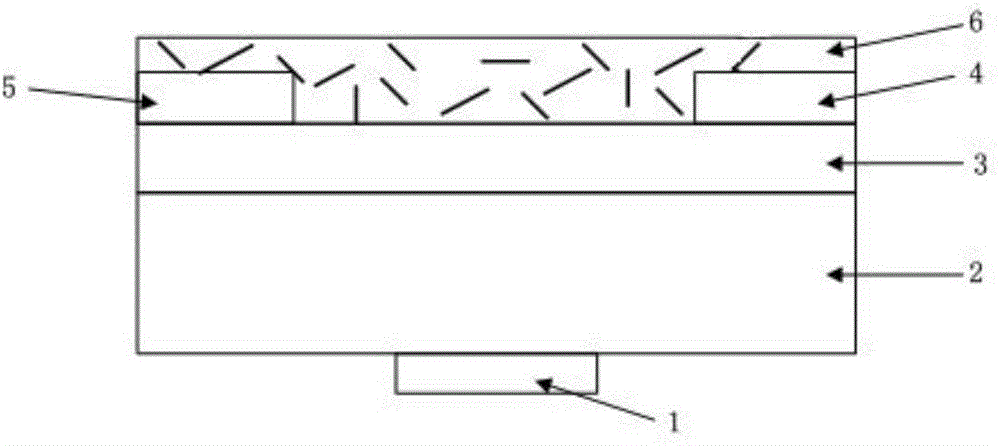

[0036] A nitrogen dioxide gas sensor, the structure of which is an organic thin film field effect transistor, comprising a gate electrode 1, a substrate 2 above the gate electrode 1, an oxide gate layer 3 above the substrate 2, and a source electrode 4 above the oxide gate layer 3 And the drain electrode 5, the active layer 6 above the source electrode 4 and the drain electrode 5, wherein the substrate is a silicon substrate, the oxide gate layer 3 is silicon dioxide, the source electrode, the gate electrode and the drain electrode are gold electrodes, and the active layer It is a composite film formed by combining ZnO nanorods and P3HT polymer. The diameter of the ZnO nanorods is 100 nm, and the length of the ZnO nanorods is 0.5 μm. In the active layer, the mass ratio of P3HT polymer and ZnO nanorods is 6:1. The sensor is a field effect transistor gas sensor with bottom gate and bottom contact. The thickness of the active layer thin film is 60nm-90nm.

[0037] The preparat...

Embodiment 2

[0043] A nitrogen dioxide gas sensor, the structure of which is an organic thin film field effect transistor, comprising a gate electrode 1, a substrate 2 above the gate electrode 1, an oxide gate layer 3 above the substrate 2, and a source electrode 4 above the oxide gate layer 3 And the drain electrode 5, the active layer 6 above the source electrode 4 and the drain electrode 5, wherein the substrate is a silicon substrate, the oxide gate layer 3 is silicon dioxide, the source electrode, the gate electrode and the drain electrode are gold electrodes, and the active layer It is a composite film formed by combining ZnO nanorods and P3HT polymer.

[0044] The diameter of the ZnO nanorods is 250 nm, and the length of the ZnO nanorods is 4 μm. In the active layer, the mass ratio of P3HT polymer and ZnO nanorods is 6:2. The sensor is a field effect transistor gas sensor with bottom gate and bottom contact.

[0045] The thickness of the active layer thin film is 60nm-90nm.

[00...

Embodiment 3

[0052] A nitrogen dioxide gas sensor, its structure is an organic thin film field effect transistor, including a gate electrode 1, a substrate 2, an oxide gate layer 3, a source electrode 4 and a drain electrode 5, and an active layer 6, wherein the substrate is a silicon lining The bottom, the oxide gate layer 3 is silicon dioxide, the source electrode, gate electrode and drain electrode are gold electrodes, and the active layer is a composite material film formed by compounding ZnO nanorods and P3HT polymer.

[0053] The diameter of the ZnO nanorods is 150 nm, and the length of the ZnO nanorods is 2 μm.

[0054] In the active layer, the mass ratio of P3HT polymer and ZnO nanorods is 6:6.

[0055] The sensor is a field effect transistor gas sensor with bottom gate and bottom contact.

[0056] The thickness of the active layer thin film is 60nm-90nm.

[0057] The preparation method of the above-mentioned nitrogen dioxide gas sensor comprises the following steps:

[0058] ①D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com