Preparation method for anti-pollution hydrophilic positive permeable membrane

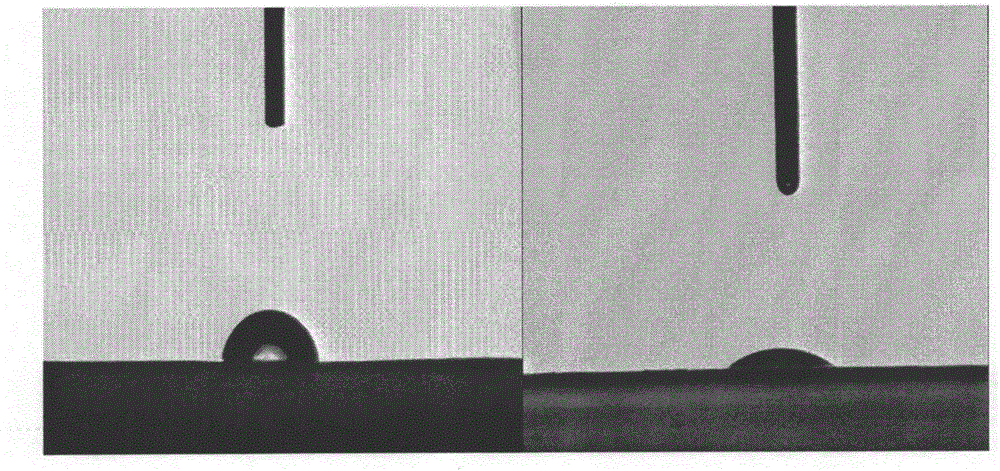

A forward osmosis membrane and hydrophilic technology, applied in the field of membrane separation, can solve the problems of numerous synthesis steps and harsh conditions, and achieve the effect of simple membrane forming process, mild conditions and convenient synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

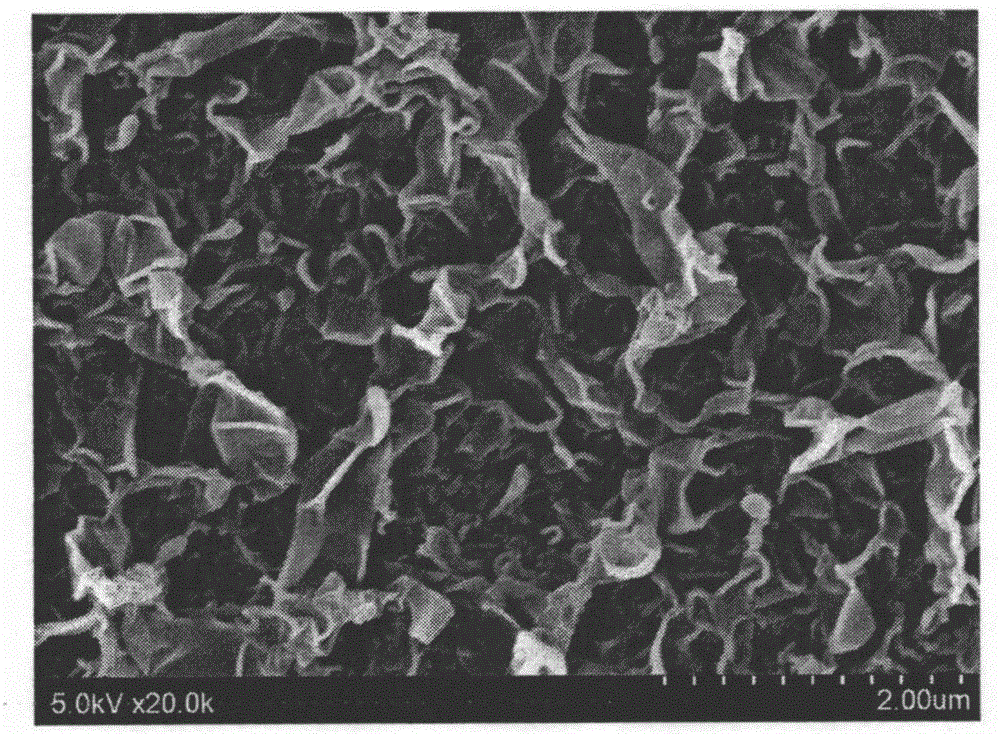

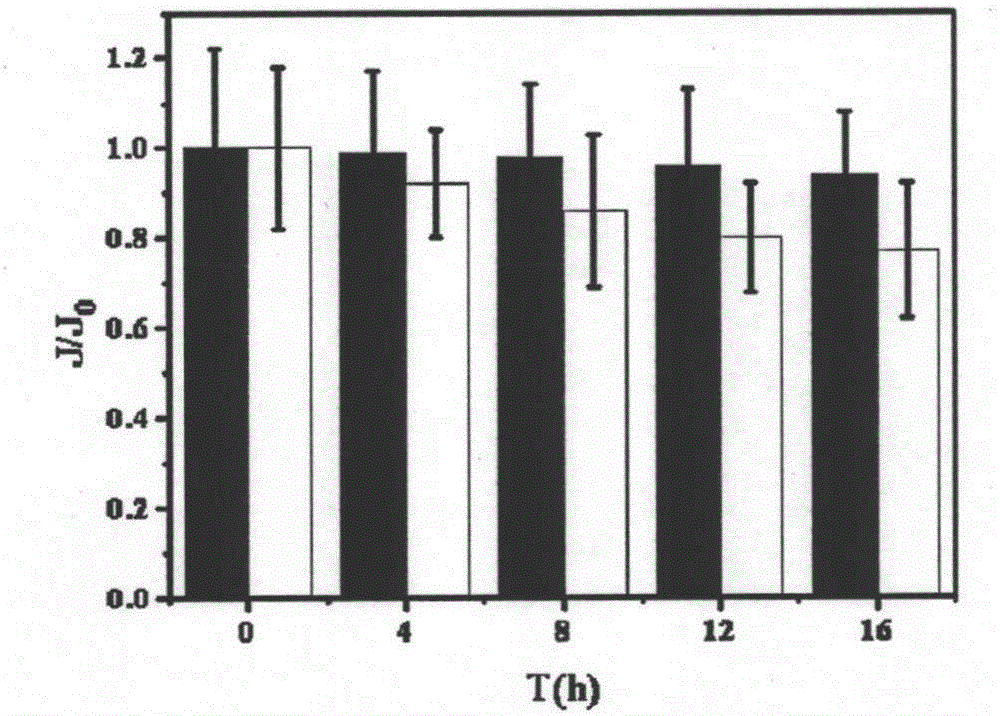

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing an anti-fouling hydrophilic forward osmosis membrane, the specific steps are:

[0029] (1) One-pot preparation of zwitterions with terminal amino groups:

[0030] Dissolve N,N-dimethyl-1,3-diaminopropane and 1,3-propane sultone in acetone solvent at a molar ratio of 1:1.1, heat up to 30°C, and mechanically stir at the same time, React for 8 hours, filter, wash the obtained dark green solid with acetone three times to remove unreacted monomer, and dry it in vacuum at 50°C for 24 hours to obtain zwitterions with terminal amino groups.

[0031] (2) Prepare polyethersulfone support layer by phase inversion method:

[0032] Dissolve 12 parts by weight of PES (BASF, UltrasonE3010) and 10 parts by weight of porogen PEG 400 in N'N-dimethylformamide (DMF) and N'N-dimethylpyrrolidone (NMP ) in 78 parts by weight of mixed solvent, heat up to 25°C, stir to dissolve for 8 hours, and let it stand for defoaming for 24 hours; take a clean and dry ordinary glass...

Embodiment 2

[0037] A method for preparing an anti-fouling hydrophilic forward osmosis membrane, the specific steps are:

[0038] (1) One-pot preparation of zwitterions with terminal amino groups:

[0039]Dissolve N,N-dimethyl-1,3-diaminopropane and 1,3-propane sultone in acetone solvent at a molar ratio of 1:1.1, heat up to 50°C, and mechanically stir at the same time, React for 6 hours, filter, wash the obtained dark green solid with acetone three times to remove unreacted monomer, and dry it in vacuum at 50°C for 24 hours to obtain zwitterions with terminal amino groups.

[0040] (2) Prepare polyethersulfone support layer by phase inversion method:

[0041] Dissolve 18 parts by weight of PES (BASF, UltrasonE3010) and 12 parts by weight of porogen PEG 400 in N'N-dimethylformamide (DMF) and N'N-dimethylpyrrolidone (NMP ) in 70 parts by weight of mixed solvent, heat up to 50°C, stir to dissolve for 8 hours, and let it stand for defoaming for 24 hours; take a clean and dry ordinary glass ...

Embodiment 3

[0046] A method for preparing an anti-fouling hydrophilic forward osmosis membrane, the specific steps are:

[0047] (1) One-pot preparation of zwitterions with terminal amino groups:

[0048] Dissolve N,N-dimethyl-1,3-diaminopropane and 1,3-propane sultone in acetone solvent at a molar ratio of 1:1.1, heat up to 50°C, and mechanically stir at the same time, React for 5 hours, filter, wash the obtained dark green solid with acetone three times to remove unreacted monomer, and dry it in vacuum at 50°C for 24 hours to obtain zwitterions with terminal amino groups.

[0049] (2) Prepare polyethersulfone support layer by phase inversion method:

[0050] Dissolve 20 parts by weight of PES (BASF, UltrasonE3010) and 10 parts by weight of porogen PEG 400 in N'N-dimethylformamide (DMF) and N'N-dimethylpyrrolidone (NMP ) in 70 parts by weight of mixed solvent, heat up to 60°C, stir to dissolve for 8 hours, and let it stand for defoaming for 24 hours; take a clean and dry common glass p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com