Gel polymer electrolyte, polymer lithium ion battery and making method of polymer lithium ion battery

A gel polymer and lithium-ion battery technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, non-aqueous electrolytes, etc., can solve problems such as low reaction conversion rate, battery performance degradation, uncontrollable polymerization, etc., to achieve reaction conversion High efficiency, inhibition of lithium dendrites, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

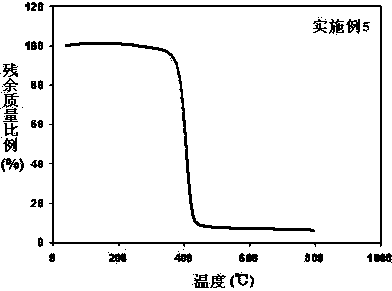

[0037] In the preparation method of the polymer lithium ion battery provided by the present invention, since the polymer film has completed self-crosslinking before being assembled into the battery (that is, it has a three-dimensional cross-linked network structure at this time), only the polymer film occurs after adding the electrolyte. The absorption of the electrolyte and the process of the three-dimensional cross-linked network structure being swollen by the electrolyte to form a gel polymer electrolyte, the process is simple and controllable, and can effectively ensure that the polymer is prepared without leakage, with greatly improved safety and good cycle stability. of lithium-ion batteries.

[0038] According to the preparation method of the present invention, the polymer mixture is first coated on the separator, the positive electrode or the negative electrode, and then the separator, the positive electrode or the negative electrode coated with the polymer mixture is t...

Embodiment 1

[0042] (1) Mix the pure acrylic emulsion with a glass transition temperature of 0 °C and water in a volume ratio of 100:10; then add 0.1% ammonia water (based on the total mass of the pure acrylic emulsion and water), and the ammonia water concentration is 25wt%, After mixing uniformly under magnetic stirring, a polymer mixed liquid was obtained.

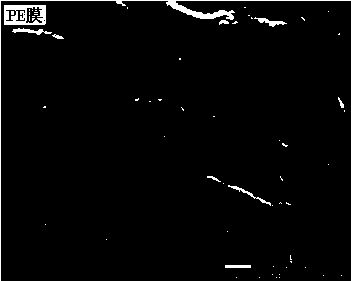

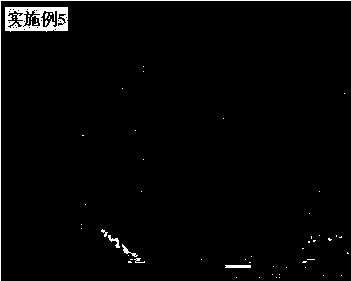

[0043] (2) The polymer mixture was coated on both sides of the PE diaphragm by a film coating machine, and baked at 85° C. for 10 h to obtain a composite diaphragm Ma1 with a polymer film on the surface. The thickness of the polymer film on the surface was 19.3 μm.

[0044] (3) The polymer mixture was cast on a PTFE plate, and baked at 85° C. for 10 hours to obtain a test film Mb1 with a polymer film on the surface.

[0045] (4) The composite membrane Ma1 was cut into discs with a diameter of 17 mm, dried at 30 °C for 12 h, and then quickly transferred to a glove box filled with argon. LiCoO 2 , binder and carbon black in a mass r...

Embodiment 2

[0047] (1) Mix the pure acrylic emulsion with a glass transition temperature of 15 °C and water in a volume ratio of 100:20, then add 0.2% ammonia water (based on the total mass of the pure acrylic emulsion and water), and the ammonia water concentration is 25wt%, After mixing uniformly under magnetic stirring, a polymer mixed liquid was obtained.

[0048] (2) The polymer mixture was coated on both sides of the PE diaphragm by a film coating machine, and baked at 75°C for 10 hours to obtain a composite diaphragm Ma2 with a polymer film on the surface, and the thickness of the polymer film on the surface was 14.2 μm.

[0049] (3) The polymer mixture was cast on a PTFE plate and baked at 75° C. for 10 h to obtain a test film Mb2 with a polymer film on the surface.

[0050] (4) The same steps as in Example 1 (4) were used to prepare the polymer lithium ion battery S20, except that Ma1 in Example 1 was replaced by a composite separator Ma2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com