Method for preparing bacterial cellulose/polyvinyl alcohol composite membrane by wet process

A technology of bacterial cellulose and polyvinyl alcohol, which is applied in the field of wet preparation of bacterial cellulose/polyvinyl alcohol composite membranes, can solve the problems of high requirements and high cost, and achieve the effects of low cost, good elasticity and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

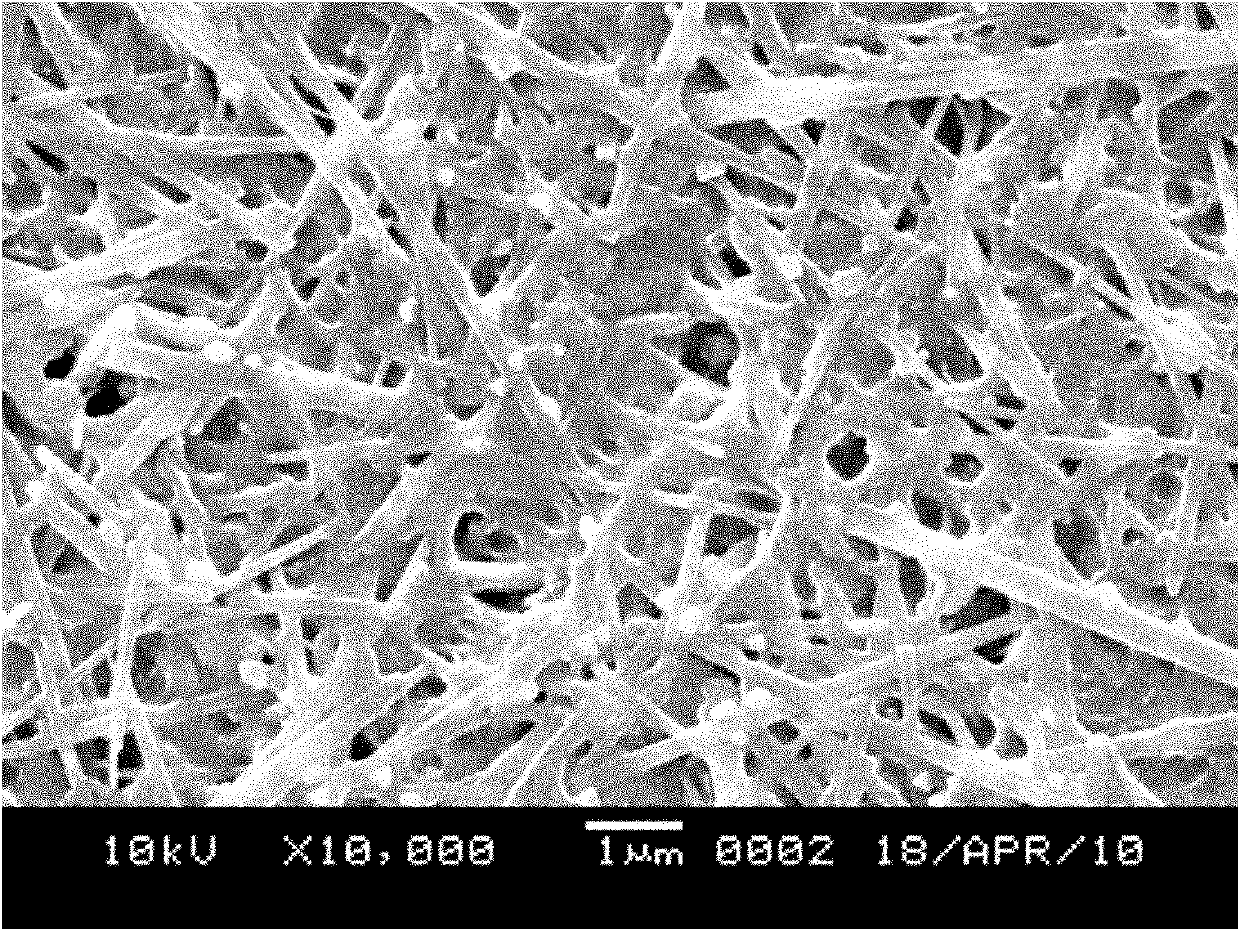

Image

Examples

Embodiment 1

[0025] (1) Place the bacterial cellulose in a container filled with water, crush it with an emulsifier, the treatment conditions are 7000-28000 rpm, 5-60min, and obtain the bacterial cellulose homogenate;

[0026] (2) Determination of the water content of the bacterial cellulose homogenate is: 98% (V / V);

[0027] (3) Distilled polyethylene with distilled water Configured as an aqueous solution with a mass concentration of 10%;

[0028] (4) Based on the moisture content of the bacterial cellulose homogenate as 98%, uniformly mix the bacterial cellulose homogenate with a 10% polyvinyl alcohol aqueous solution in a mass ratio of 1:10;

[0029] (5) Spread the mixture evenly in the mold of the glassware, and make the thickness 0.500-2.500mm. After defoaming, place it at room temperature for 12 hours, and then add it to 100ml of supersaturated K 2 SO 4 In the solution, use 2ml of 37wt% formaldehyde solution to cross-link for 30 minutes at a pH of 1.5 and a temperature of 80° C. ...

Embodiment 2

[0032] (1) Place the bacterial cellulose in a container filled with water, crush it with an emulsifier, the treatment conditions are 7000-28000 rpm, 5-60min, and obtain the bacterial cellulose homogenate;

[0033] (2) Determination of the water content of the bacterial cellulose homogenate is: 98% (V / V);

[0034] (3) Polyvinyl alcohol is configured into an aqueous solution with a mass concentration of 15% with distilled water;

[0035] (4) Taking the water content of the bacterial cellulose homogenate as 98%, uniformly mixing the bacterial cellulose homogenate with a polyvinyl alcohol aqueous solution with a concentration of 15% in a mass ratio of 1:8;

[0036] (5) Spread the mixture evenly in a plexiglass mould, and make the thickness 0.500-2.500mm. After defoaming, place it at room temperature for 15 hours, and then add it to 100ml of supersaturated (NH 4 ) 2 SO 4 In the solution, 2.5ml of 40wt% acetaldehyde solution was used to crosslink for 20 minutes at a pH of 1.5 and...

Embodiment 3

[0039] (1) Place the bacterial cellulose in a container filled with water, crush it with an emulsifier, the treatment conditions are 7000-28000 rpm, 5-60min, and obtain the bacterial cellulose homogenate;

[0040] (2) measure the moisture content of bacterial cellulose homogenate: 98% (V / V);

[0041] (3) Polyvinyl alcohol is configured into an aqueous solution with a mass concentration of 5% with distilled water;

[0042] (4) On the basis of the moisture content of the bacterial cellulose homogenate being 98%, the bacterial cellulose homogenate is uniformly mixed with a polyvinyl alcohol solution having a concentration of 5% in a mass ratio of 1:6;

[0043] (5) Spread the mixture evenly in the ceramic mold, and make the thickness 0.500~2.500mm, defoam and place it at room temperature for 18h, and then add it to 100ml of supersaturated Na 2 SO 4 3ml of 30wt% glyoxal solution was used in the solution to cross-link for 20 minutes at a pH of 2.5 and a temperature of 80° C. to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com